Preparation method of microchannel array plate, device for acquiring liquid drops by the same and liquid drop generation method

A micro-channel plate and micro-channel technology, applied in chemical instruments and methods, transportation and packaging, fluid controllers, etc., can solve problems such as poor experimental parallelism, low success rate, and difficulty in achieving high-throughput production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] The cooperation of embodiment 1 microchannel plate and collection device

[0104] Microchannel plate with 1.5mL centrifuge tube

[0105] Add 1ml of the second liquid into the centrifuge tube. Because the second liquid is easy to generate air bubbles, it must be added slowly. After the air bubbles are formed, you can use a 1ml pipette to replace the tip with a new pipette, and quickly aim at the air bubbles to pump out the air. The air bubbles will disappear immediately. was blown apart.

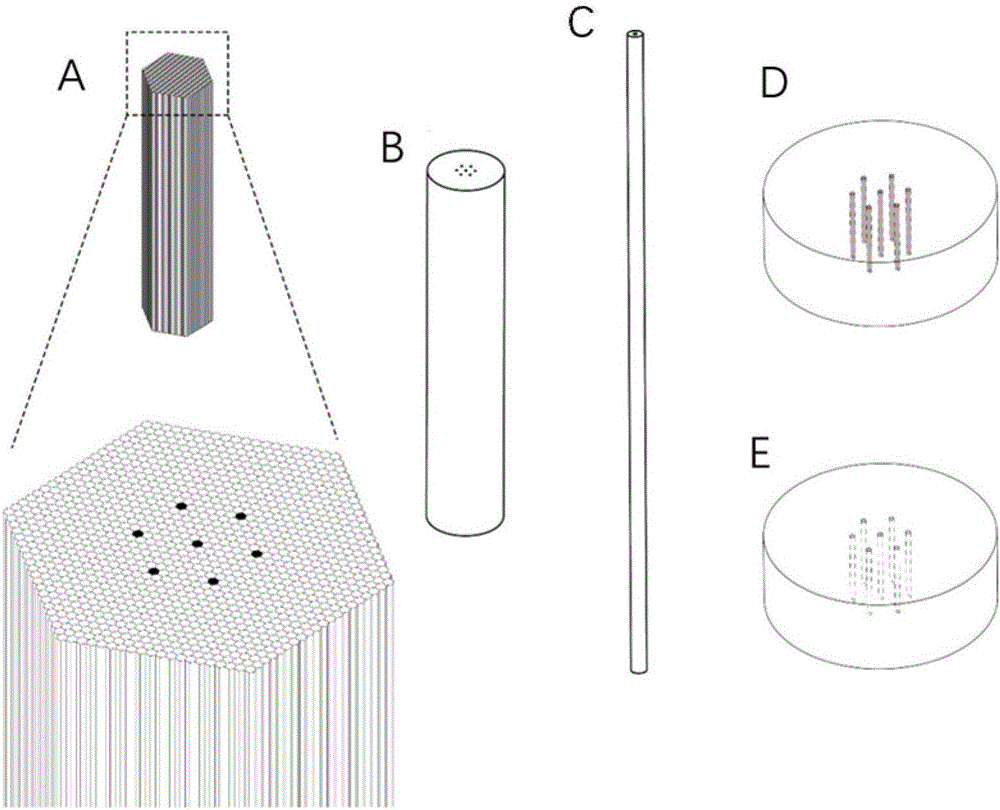

[0106] Assembly diagram as Figure 4 shown. 1 bolt, 1.1 bolt head, 1.2 bolt lower surface, 1.3 male thread, 1.4 through hole, 2 spacer, 3 microchannel array plate, 4 connection part, 4.1 connection part head, 4.2 connection part lower end surface, 4.3 female thread, 4.4 Inner end, 5 1.5mL centrifuge tubes (the caps are omitted here). After the two threads are tightened, fix the microchannel plate and place it lightly in the centrifuge tube filled with the second liquid.

[0107] M...

Embodiment 2

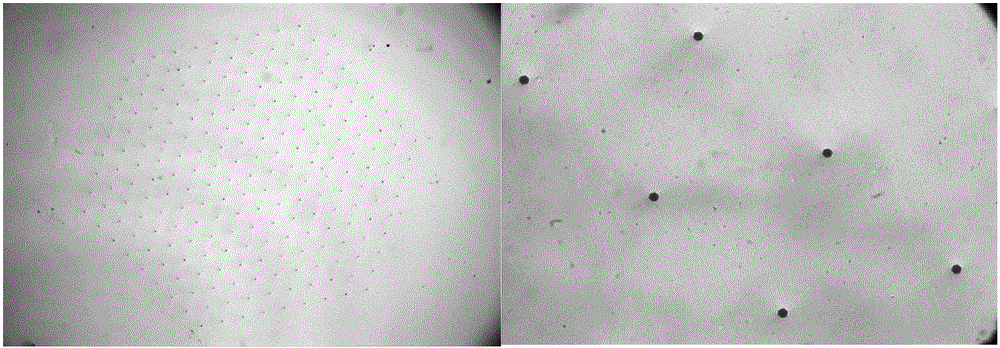

[0111] The droplets produced by the device of the present invention are used in digital chain reaction (dPCR) detection of trace DNA samples based on TaqMan probes

[0112] The second liquid formulation in this example was isopropyl laurate / Abilem 180 v / v 83 / 17 solution and the collection device was a 1.5 ml centrifuge tube.

[0113] The preparation method of the first liquid

[0114] First prepare the following mixture (1), wherein the primers are designed based on a 223bp sequence in lambda phage DNA for PCR amplification, and TaqMan probes are also designed based on this sequence.

[0115]

[0116]After obtaining the mixed solution (1), take 99 μl of the mixed solution and add 1 μl of DNA template. This DNA template is the product after agarose gel purification, and its concentration is determined by Nanodrop. Add 1 μl of 1.00*10^6 copy and 1 μl of 1.00*10^5 to 99 μl of the mixture (1) respectively to obtain reaction samples A and B. in

[0117]

A

B

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com