Preparation method of meerschaum-loaded porphyrin-sensitized Bi2WO6 visible light-driven photocatalyst

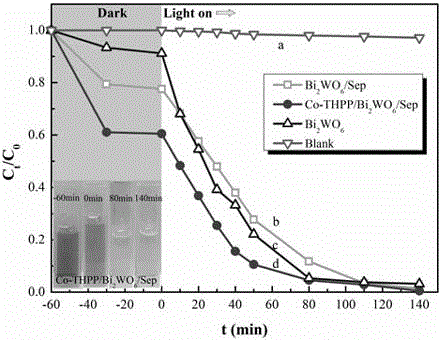

A sepiolite, visible light technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high photogenerated electron-hole recombination rate and organic matter degradation. It can improve the adsorption and enrichment capacity, promote separation, and excellent visible light catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

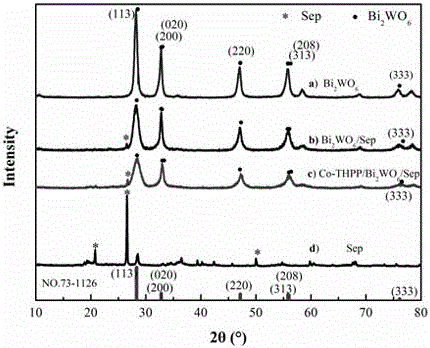

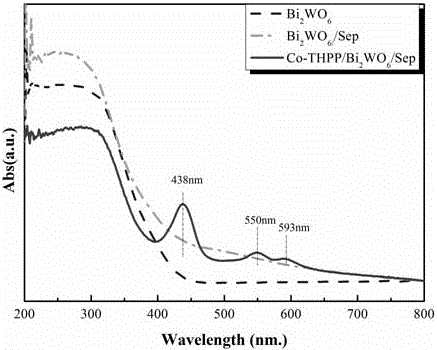

[0022] Co-THPP / Bi 2 WO 6 / Acid-modified sepiolite composite visible light catalyst (Co-THPP / Bi 2 WO 6 / Acid-Sep) preparation, including the following steps:

[0023] (1) Slowly add purified sepiolite to a mass fraction of 10% HCl (liquid-solid mass ratio 10:1), stir at room temperature for 2 hours, remove the supernatant after the reaction is complete, wash with water until neutral, and dry in an oven Dry it and grind it finely. Calcined at 500°C for 5 hours in a muffle furnace to obtain acid-modified sepiolite.

[0024] (2) Dissolve Na with deionized water 2 WO 4 2H 2 O (0.5 g), add the above modified sepiolite (5 g) and stir for 0.5 h. Add Bi(NO 3 ) 3 ·5H 2 O, and 1~3mg of cobalt-tetrakis-(p-hydroxyphenyl)porphyrin (Co-THPP), stirred at room temperature for 8 hours, then transferred to a hydrothermal kettle, and reacted at 150°C for 24 hours.

[0025] (3) Naturally cool the hydrothermal reaction product in step (2) to room temperature, filter and wash three time...

Embodiment 2

[0031] MgTHPP / Bi 2 WO 6 / Acid-modified sepiolite composite visible light catalyst (Mg-THPP / Bi 2 WO 6 / Acid-Sep) preparation, including the following steps:

[0032] (1) Slowly add purified sepiolite to 12% HCl (liquid-solid mass ratio 10:1), stir at room temperature for 3 hours, remove the supernatant after the reaction is complete, wash with water until neutral, and place in an oven to dry Dry it and grind it finely. Calcined at 500°C for 4 hours in a muffle furnace to obtain acid-modified sepiolite.

[0033] (2) Dissolve Na with deionized water 2 WO 4 2H 2 O (0.5 g), add the above modified sepiolite (5 g) and stir for 1 h. Add Bi(NO 3 ) 3 ·5H 2 O, and 1~3mg of magnesium-tetrakis-(p-hydroxyphenyl)porphyrin (Mg-THPP), stirred at room temperature for 3 hours, then transferred to a hydrothermal kettle, and reacted at 180°C for 16 hours.

[0034] (3) Naturally cool the hydrothermal reaction product in step (2) to room temperature, filter and wash 4 times with deioniz...

Embodiment 3

[0037] ZnTHPP / Bi 2 WO 6 / Acid-modified sepiolite composite visible light catalyst (Zn-THPP / Bi 2 WO 6 / Acid-Sep) preparation, including the following steps:

[0038] (1) Slowly add purified sepiolite to a mass fraction of 8% HCl (liquid-solid mass ratio 10:1), stir for 4 hours at room temperature, remove the supernatant after the reaction is complete, wash with water until neutral, and dry in an oven Dry it and grind it finely. Calcined at 400°C for 6 hours in a muffle furnace to obtain acid-modified sepiolite.

[0039] (2) Dissolve Na with deionized water 2 WO 4 2H 2 O (0.5 g), add the above modified sepiolite (5 g) and stir for 1.5 h. Add Bi(NO 3 ) 3 ·5H 2 O, and 1~3mg of zinc-tetrakis-(p-hydroxyphenyl)porphyrin (Zn-THPP), stirred at room temperature for 15 hours, then transferred to a hydrothermal kettle, and reacted at 140°C for 48 hours.

[0040] (3) Naturally cool the hydrothermal reaction product in step (2) to room temperature, filter and wash twice with de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com