Preparation method and application of titanium dioxide-graphene oxide-carbon composite material (TiO2-GO-AC)

A carbon composite material, titanium dioxide technology, applied in chemical instruments and methods, special compound water treatment, physical/chemical process catalysts, etc. and other problems, to achieve the effect of improving catalytic activity, reducing manufacturing cost, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

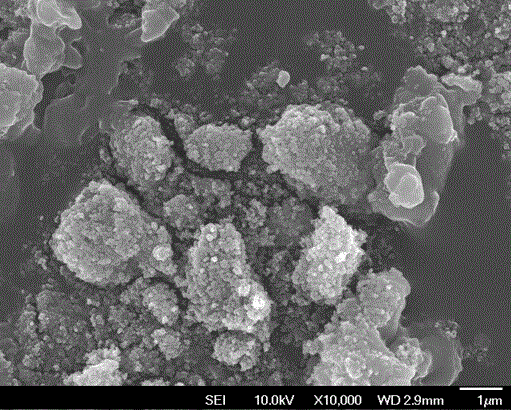

[0017] Sonicate 31.25ml GO for 1h, add 0.125g titanium dioxide powder, add coal-based activated carbon (abbreviated as AC1), stir for 0.5h, then transfer the mixture to a 50ml hydrothermal reactor, put it in a drying oven at 180°C for 12h. After cooling, filter with suction and wash with water until there is no Cl - (tested with silver nitrate solution), and then vacuum-dried at 60°C to obtain the composite photocatalyst TiO formed by activated carbon supported titanium dioxide-GO 2 -GO-AC l).

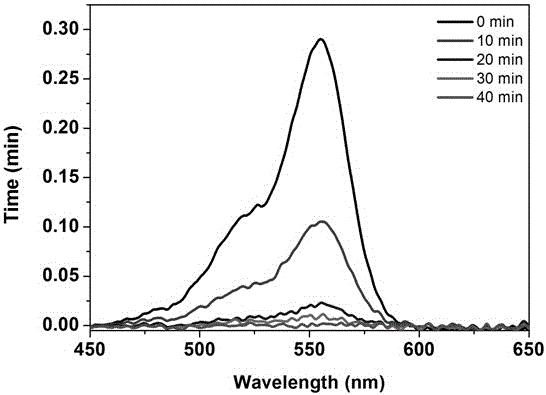

[0018] During the experiment, 50 ml Rhodamine B (2×10 -4 mol / L) solution is placed in the reactor, adding TiO 2 - GO-ACl particles 72.46 mg. Stir for 30 min in the black box under the condition of ventilation, so that the adsorption of Rhodamine B on the surface of titanium dioxide particles is balanced, and then, take 0.5 ml slurry from the reactor for centrifugation, and the concentration of Rhodamine B in the supernatant is marked as C 0 . Then turn on the light source to carry...

Embodiment 2

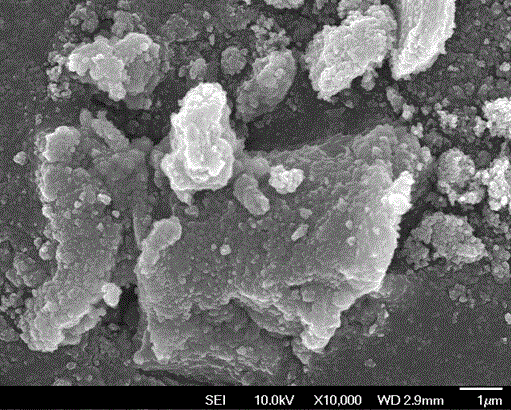

[0020] Ultrasound 31.25ml of GO for 1 hour, add 0.125g of titanium dioxide powder, add 0.025g of coconut shell activated carbon (abbreviated as AC2), stir for 0.5h, then transfer the mixture to a 50ml hydrothermal reaction kettle, put it in a drying oven and react at 180°C 12h. After cooling, filter with suction, wash with water until there is no Cl- (tested with silver nitrate solution), and then vacuum-dry at 60°C to obtain the composite photocatalyst TiO formed by supporting titanium dioxide on activated carbon. 2 -GO-AC2).

[0021] During the experiment, 50 ml Rhodamine B (2×10 -4 mol / L) solution is placed in the reactor, adding TiO 2 - GO-AC2 Granules 72.46 mg. Stir in the black box for 30 min under the condition of air ventilation to balance the adsorption of Rhodamine B on the surface of titanium dioxide particles. Then, take 0.5 ml slurry from the reactor for centrifugation, and the concentration of Rhodamine B in the supernatant is marked as C0. Then turn on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com