Method for preparing monolith catalyst

A monolithic catalyst, catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc. The effect of reducing investment costs, realizing economic benefits, and stabilizing long-term economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

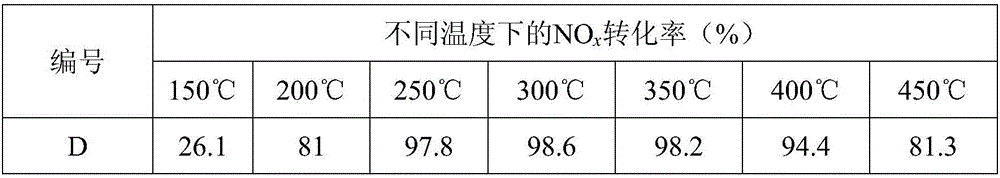

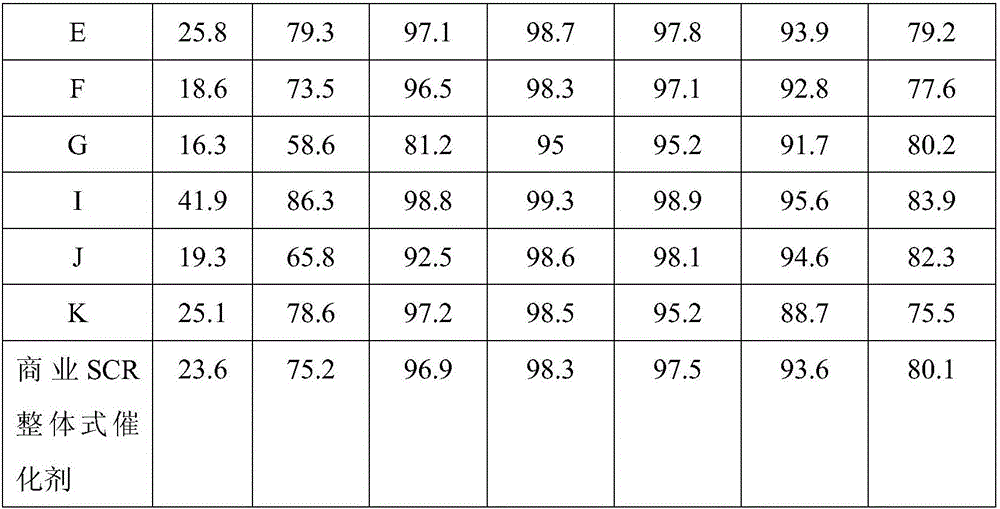

Examples

Embodiment 1

[0062] After preparing a mixed solution with oxalic acid as co-solvent, ammonium metavanadate as vanadium source and ammonium tungstate as tungsten source, add TiO 2 The powder is used as a carrier, and it is fully stirred for more than 1 hour, then the mixed solution is rotary evaporated until the water is fully volatilized, and dried in an air atmosphere at 100°C for 12 hours, and finally roasted in an air atmosphere at 550°C for 3 hours to obtain a load of 4.5wt%V 2 o 5 and 10wt% WO 3 V 2 o 5 -WO 3 / TiO 2 Catalyst, referred to as Catalyst A.

Embodiment 2

[0064] After preparing ammonium metavanadate solution with oxalic acid as co-solvent, add WO 3 Content is 10wt% titanium tungsten powder (10% WO 3 -TiO 2 powder) as a carrier, fully stirred for more than 1 hour, and then the mixed solution was rotatably evaporated until the water was fully volatilized, dried at 100°C for 12 hours, and finally roasted at 550°C for 3 hours to obtain 3% V 2 o 5 / 10% WO 3 -TiO 2 Catalyst, referred to as Catalyst B.

Embodiment 3

[0066] After preparing ammonium metavanadate solution with oxalic acid as co-solvent, add WO 3 Content is 5wt% titanium tungsten powder (5% WO 3 -TiO 2 Powder) as a carrier, fully stirred for more than 1h, then dried the mixed solution in an air atmosphere at 100°C until the water was fully volatilized, and finally roasted in an air atmosphere at 500°C for 3h to obtain 3.5% V 2 o 5 / 5% WO 3 -TiO 2 Catalyst, referred to as Catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com