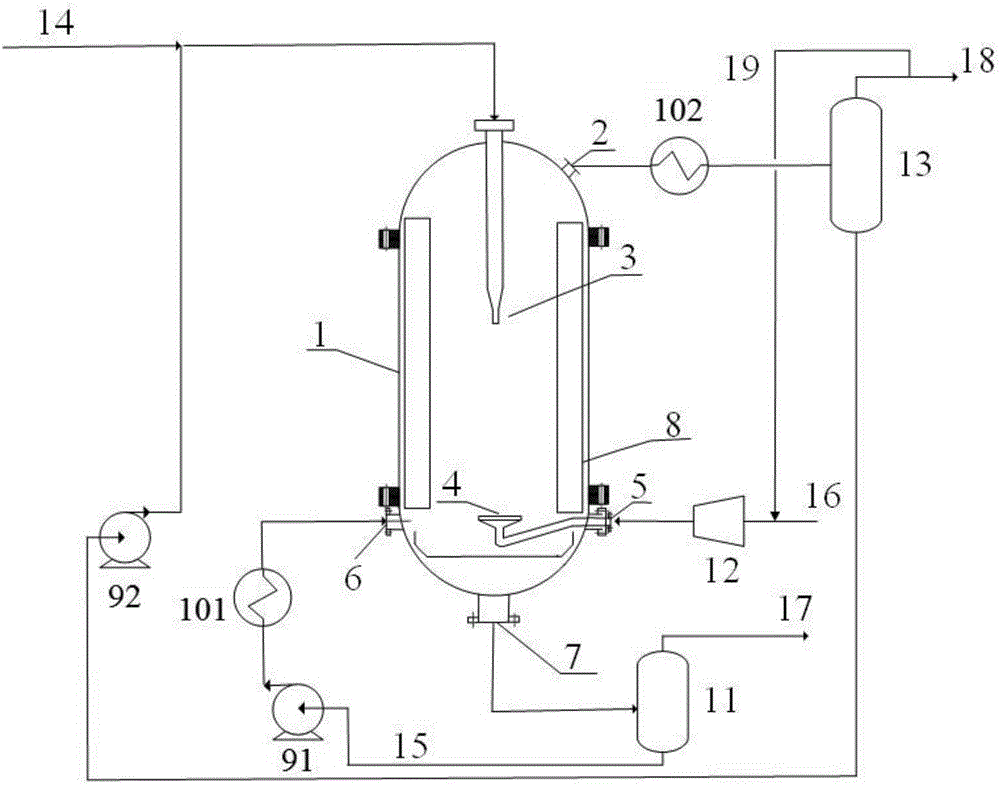

Gas-liquid two-phase jet flow reactor and gas-liquid two-phase jet flow reaction system

A technology of jet reactor and reaction system, applied in the reaction of liquid and gas under foam/aerosol/bubble, chemical method for reacting liquid and gas medium, chemical/physical/physicochemical nozzle reactor, etc. , can solve the problems of not achieving the best gas-liquid mixing effect, complex reactor structure, etc., and achieve the effects of reducing mechanical maintenance costs, good gas-liquid mixing effect, and increasing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

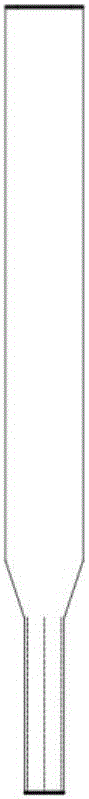

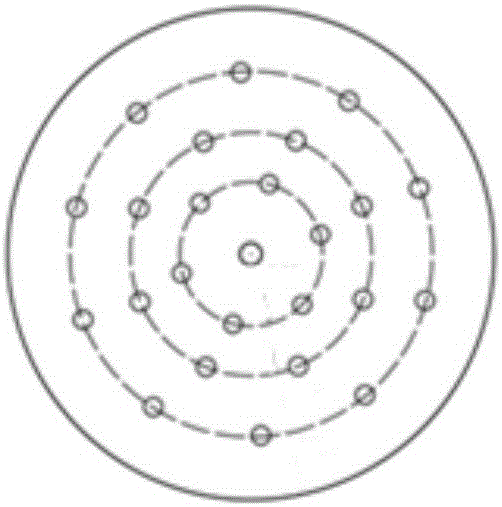

[0037] The height-to-diameter ratio of the gas-liquid two-phase jet reactor is 4:1; the ratio of the length of the reduced-diameter nozzle to the height of the cylinder is 1:2.5, and the length of the reduced-diameter nozzle after shrinking and the length before shrinking The ratio is 1:8; the inlet and outlet flow sections are circular, the ratio of the diameter of the inlet flow section to the diameter of the cylinder is 0.1:1, and the ratio of the diameter of the inlet flow section to the outlet flow section is 1:0.6; The ratio of the diameter of the gas distributor 4 to the diameter of the cylinder is 0.29:1, the number of opening circles is 4 layers, the ratio of the number of openings in each circle is 1:6:8:10, the diameter of the aperture and the diameter of the gas distributor The ratio is 1:40. The number of baffles is 4, the ratio of the length to the height of the cylinder is 1:1, the ratio of the width to the diameter of the cylinder is 0.15:1, and the ratio of th...

Embodiment 2

[0044] The height-to-diameter ratio of the gas-liquid two-phase jet reactor is 4:1, the ratio of the length of the reduced-diameter nozzle to the height of the cylinder is 1:2.5, and the ratio between the length of the reduced-diameter nozzle and the length before the diameter reduction is 1:2.5. The ratio is 1:8; the inlet and outlet flow sections are circular, the ratio of the diameter of the inlet flow section to the diameter of the cylinder is 0.08:1, and the ratio of the diameter of the inlet flow section to the outlet flow section is 1:0.6; The ratio of the diameter of the gas distributor 4 to the diameter of the cylinder is 0.29:1, the number of opening circles is 4 layers, the ratio of the number of openings in each circle is 1:8:8:10, and the ratio of the hole diameter to the diameter of the original disk The ratio is 1:35. The number of baffles is 5, the ratio of the length to the height of the cylinder is 1:1, the ratio of the width to the diameter of the cylinder i...

Embodiment 3

[0050] The height-to-diameter ratio of the gas-liquid two-phase jet reactor is 4:1; the ratio of the length of the reduced-diameter nozzle to the height of the cylinder is 1:2.5, and the length of the reduced-diameter nozzle after shrinking and the length before shrinking The ratio is 1:8; the inlet and outlet flow sections are circular, the ratio of the diameter of the inlet flow section to the diameter of the cylinder is 0.08:1, and the ratio of the diameter of the inlet flow section to the outlet flow section is 1:0.55; The ratio of the diameter of the gas distributor 4 to the diameter of the reactor cylinder is 0.29:1, the number of opening circles is 4 layers, the ratio of the number of openings in each circle is 1:8:10:10, the diameter of the aperture and the diameter of the original disk The ratio is 1:35. The number of baffles is 4, the ratio of the length to the height of the cylinder is 1:1, the ratio of the width to the diameter of the reactor cylinder 1 is 0.15:1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com