Zinc-selenium tea processing technology

A processing technology, selenium tea technology, applied in the direction of tea extraction, tea treatment before extraction, etc., can solve the problems of zinc and selenium element loss, inconvenient processing operation, dependence on manual operation, etc., to reduce labor time and production cost , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

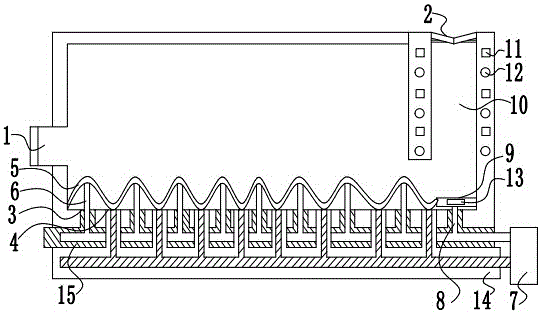

Image

Examples

Embodiment 1

[0032] Step 1: Classify the tea leaves, spread the green tea picked from the mountain on the inclined mesh screen, and the screen is connected with a motor that can make the screen swing and rotate at a constant speed; The weight of the leaves is different, the lighter tender leaves gradually leave the screen during the swing of the screen, and the young leaves fall into the bamboo basket for holding the tender leaves placed near the slanted lower end of the screen; when only the old leaves are left on the screen When pressing the switch used to control the overturning of the screen, the screen stops swinging and rotates in an upwardly inclined direction, and the old leaves on the screen fall into another bamboo basket that is placed on the original inclined upward end of the screen to load the old leaves; After the classification of young leaves and old leaves is completed, all kinds of tea leaves are cleaned and removed for later use;

[0033] Step 2: Tea treatment, soaking ...

Embodiment 2

[0042] Step 1: Classify the tea leaves, spread the green tea picked from the mountain on the inclined mesh screen, and the screen is connected with a motor that can make the screen swing and rotate at a constant speed; According to the difference in weight, the lighter tender leaves will gradually leave the screen while the screen is swinging, and the tender leaves will fall into the bamboo basket for holding tender leaves placed near the inclined downward end of the screen; when only the old leaves are left on the screen Press the switch used to control the overturning of the sieve, the sieve stops swinging and rotates in an upward direction, and the old leaves on the sieve fall into another bamboo basket placed on the slanting upper end of the sieve to load the old leaves ; After the classification of young leaves and old leaves is completed, all kinds of tea leaves are cleaned and removed for later use;

[0043] Step 2: Tea treatment, soak the old leaves prepared in step 1 ...

Embodiment 3

[0052] Step 1: Classify the tea leaves, spread the green tea picked from the mountain on the inclined mesh screen, and the screen is connected with a motor that can make the screen swing and rotate at a constant speed; The weight of the leaves is different, the lighter tender leaves gradually leave the screen during the swing of the screen, and the young leaves fall into the bamboo basket for holding the tender leaves placed near the slanted lower end of the screen; when only the old leaves are left on the screen When pressing the switch used to control the overturning of the screen, the screen stops swinging and rotates in an upwardly inclined direction, and the old leaves on the screen fall into another bamboo basket that is placed on the original inclined upward end of the screen to load the old leaves; After the classification of young leaves and old leaves is completed, all kinds of tea leaves are cleaned and removed for later use;

[0053] Step 2: tea processing, the old...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com