Sterile cultivation device capable of achieving automatic monitoring and regulation of multiple culture conditions

A technology of culture conditions and automatic monitoring, applied in the field of plant tissue culture, can solve the problems of bacteria contamination and unstable external environment, and achieve the effect of simple and convenient operation and automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

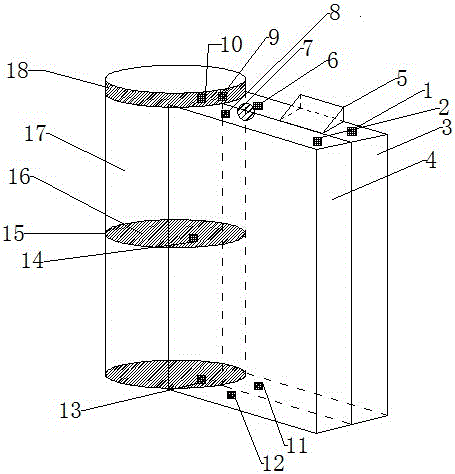

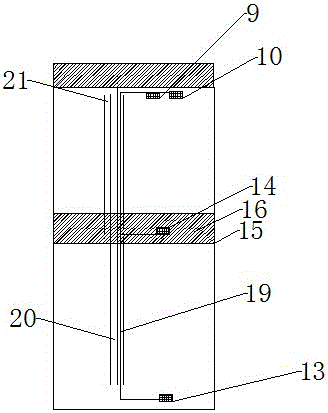

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as figure 1 and 2 as shown,

[0013] The aseptic cultivation device capable of automatically monitoring and regulating a plurality of cultivation conditions of the present invention comprises: a water inlet 1, a water outlet 2, a water storage tank 3, a waste water tank 4, a CPU microprocessor 5, and an aqueduct interface 6 with a bacteria-filtering film , multi-interface suction pump 7, water guide pipe interface 8, oxygen / carbon dioxide concentration meter 9, temperature sensitive sensor 10, pH meter 11, pressure sensor 12, ion concentration detector 13, humidity sensor 14, clapboard 15, seedling raising sponge 16, Cultivation device main body 17, cultivation device cover 18, sensor line channel 19, water guide channel 20 and water injection channel 21, water inlet 1 and water outlet 2 are respectively located on water storage tank 3 and waste water tank 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com