Ethylene-alpha-olefin copolymer and olefin resin composition

一种烯烃共聚物、烯烃系树脂的技术,应用在聚烯烃系树脂改性用乙烯-α-烯烃共聚物领域,能够解决强度、透明性降低、改良水平不充分、乙烯系聚合物设计不充分等问题,达到改良效果优异、冲击强度与刚性的均衡性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0157] Preparation of sample: ODCB (containing 0.5 mg / mL of BHT) was used as a sample, a 1 mg / mL solution was prepared, and it was dissolved at 140° C. for about 1 hour.

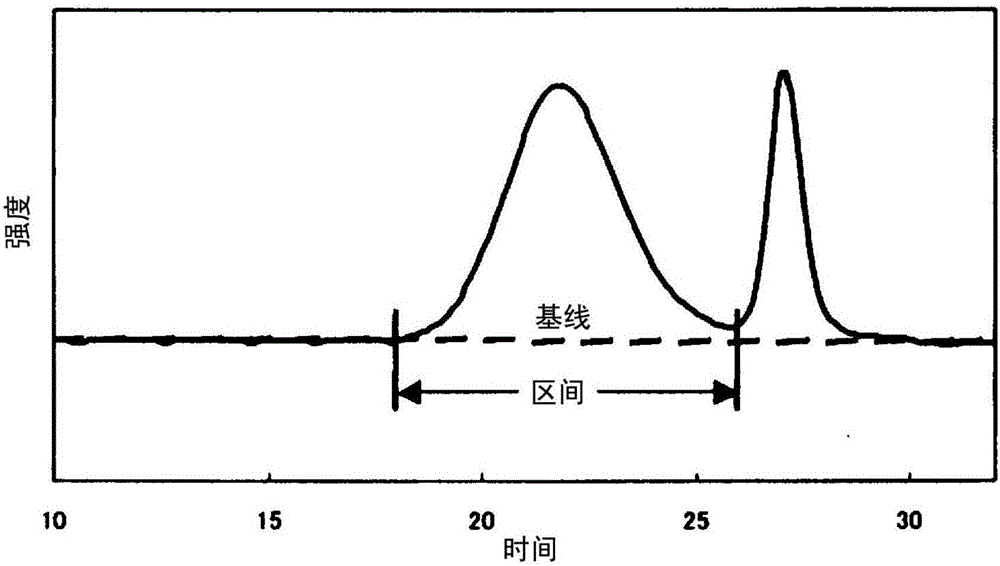

[0158] It should be noted that the baseline and interval of the obtained chromatogram are as follows figure 1 Proceed as shown.

[0159] 1-7. Conditions (4)

[0160] The ratio (Mz / Mw) of the Z weight average molecular weight (Mz) to the weight average molecular weight (Mw) of the ethylene-α-olefin copolymer in the present invention is 2.0 to 6.0, preferably 2.1 to 5.5, more preferably 2.2 to 5.3 , more preferably more than 2.2 and less than 5.0, particularly preferably 2.3 to less than 3.6. When Mz / Mw is less than 2.0, moldability, especially melt fluidity, when blended with a polyolefin resin is poor, or it is difficult to mix with other polymer components, so it is preferably avoided. When Mz / Mw exceeds 6.0, the improvement effect of the rigidity and impact strength of the polyolefin resin and its mold...

Embodiment 1

[0335] (1) Synthesis of bridged cyclopentadienyl indenyl compounds;

[0336] According to the method described in [0140] to [0143] of Japanese Patent Laid-Open No. 2013-227271, dimethylsilylene (4-(4-trimethylsilyl-phenyl)-indene was synthesized by the following method base) (cyclopentadienyl) zirconium dichloride.

[0337] (II) Materials used

[0338] [Synthesis of Metallocene Compounds]

[0339] (i) Metallocene compound A: Synthesis of dimethylsilylene (4-(4-trimethylsilyl-phenyl)-indenyl)(cyclopentadienyl)zirconium dichloride

[0340] (1-1) Synthesis of 4-(4-trimethylsilyl-phenyl)-indene

[0341] Add 10.0g (51.5mmol) of 4-trimethylsilylphenylboronic acid and 200ml of dimethoxyethane into a 500ml flask to form a solution, then add 27.3g (128mmol) of potassium phosphate, 100ml of water, and 4-bromo Indene 8.37g (43.0mmol), triphenylphosphine 0.22g (0.86mmol), PdCl 2 (PPh 3 ) 2 0.300g (0.430mmol), stirred and refluxed for 12 hours. Cool to room temperature and add 100...

Embodiment 2

[0352] (1) Synthesis of catalysts for olefin polymerization;

[0353] In a nitrogen atmosphere, 30 g of silica obtained by firing at 400° C. for 5 hours was added to a 500 ml three-necked flask, and then 195 ml of dehydrated toluene was added to form a slurry. Under a nitrogen atmosphere, add the dimethylsilylene (4-(4-trimethylsilyl-phenyl)-indene synthesized in Example 1 (1) to a separately prepared 200ml two-necked flask Base) 410 mg of (cyclopentadienyl) zirconium dichloride was dissolved in 80.4 ml of dehydrated toluene, and then 82.8 ml of 20% methylalumoxane / toluene solution manufactured by Albemarle Corporation was added at room temperature, and stirred for 30 minutes. A 500ml three-necked flask to which the toluene slurry solution of silica was added was heated and stirred in an oil bath at 40° C., and the toluene solution of the reactant of the zirconocene complex and methylaluminoxane was added in a total amount. After stirring at 40° C. for 1 hour, the mixture was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com