Micro-channel side air-out condenser and mounting method thereof

A condenser and microchannel technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve uneven refrigerant flow, affect heat exchange effect, and difficult to distribute gas-liquid two-phase refrigerant uniformly, etc. problem, to achieve good heat dissipation effect, improve heat dissipation effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

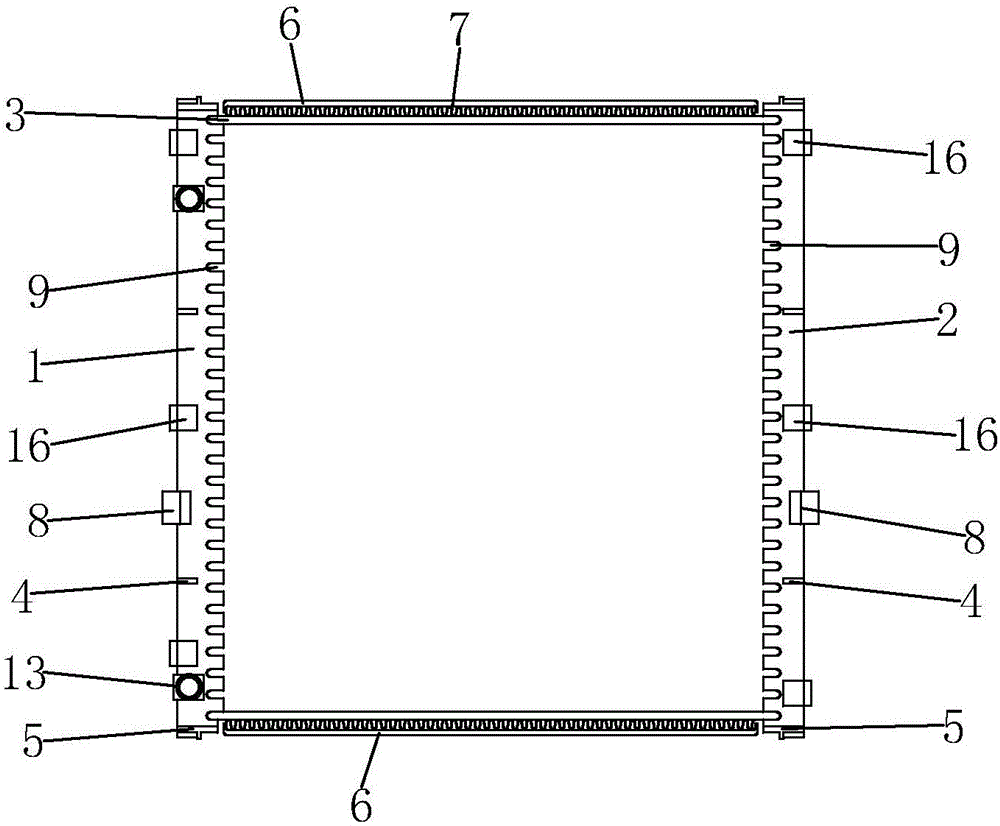

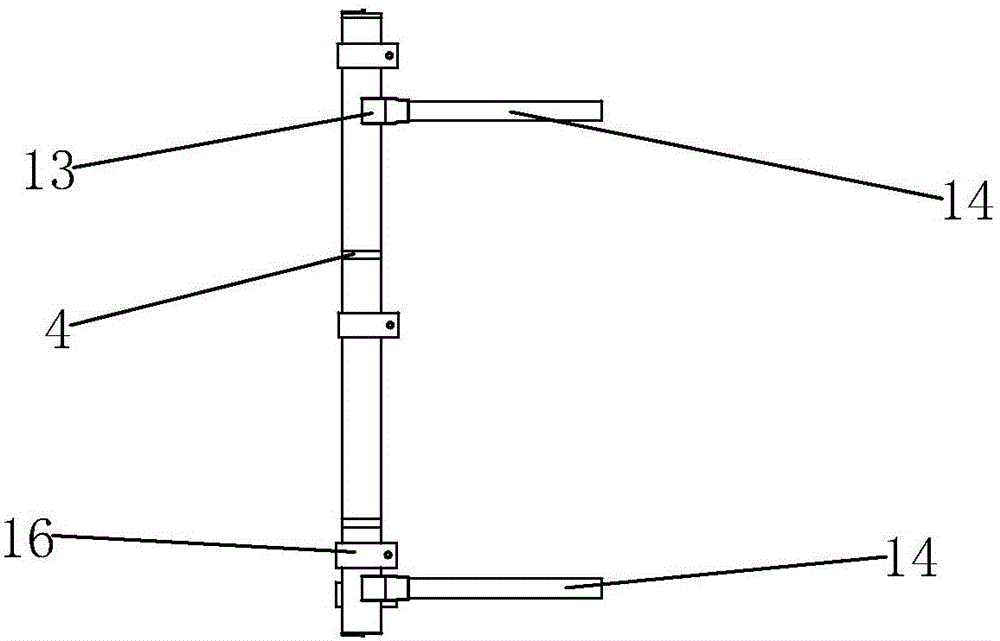

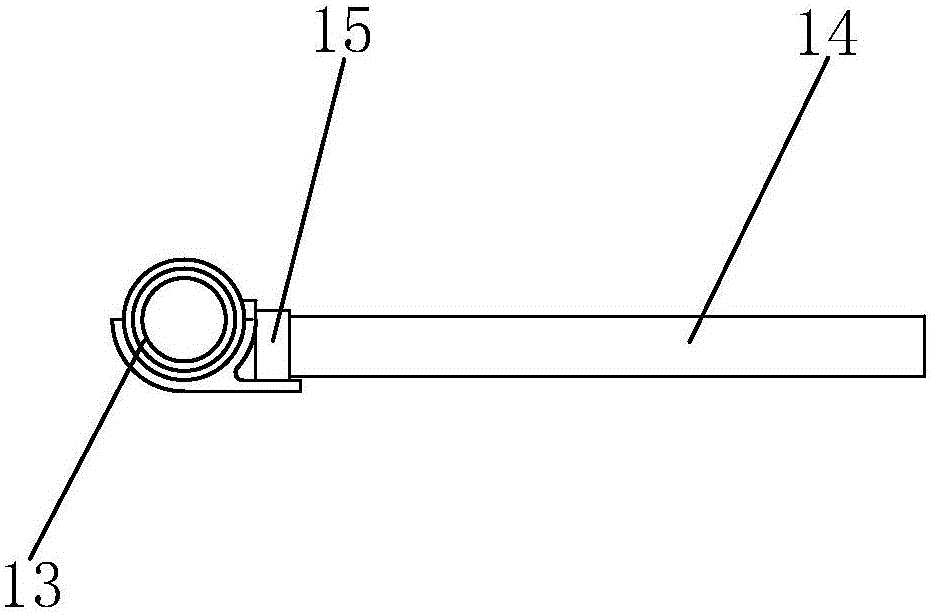

[0031] Such as Figure 1-6 Shown is a micro-channel side air outlet condenser of the present invention, which includes a first header 1, a second header 2, a flat tube 3, a partition 4, an end cover 5, a side plate 6 and a fin 7 , The first header 1 and the second header 2 are both equipped with a pressure-holding accessory 8. The setting of the pressure-holding accessory 8 can maintain the working pressure required by the first header 1 and the second header 2 and avoid The components are damaged due to pressure changes to ensure normal heat exchange efficiency, protect the first header 1 and the second header 2, and prolong the service life of the first header 1 and the second header 2. The partitions 4 are both arranged in the first header 1 and the second header 2, and the partitions 4 seal the inner cavity of the header into multiple chambers.

[0032] Notched grooves 9 are evenly distributed on the first header 1 and the notched grooves 9 are evenly distributed on the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com