Slow-recovery foam with low temperature resistance and high density as well as preparation method thereof

A slow-rebound sponge and high-density technology, which is applied in the field of organic polymer synthesis, can solve problems such as poor bearing capacity, particularly large impact on hardness, and low density, and achieve cost-saving and good hole-opening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

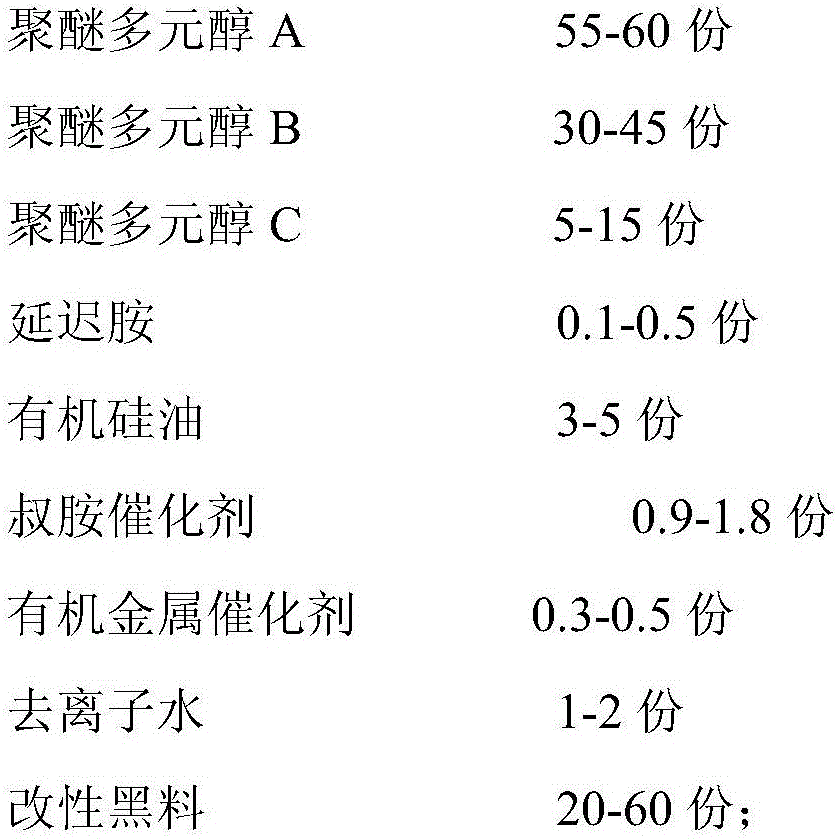

[0028] (1) Polyether polyol A (hydroxyl value 40, functionality 3, polyoxypropylene oxide triol) 55g, polyether polyol B (hydroxyl value 50, functionality 4, polyoxypropylene triol) 45g, Add 15g of polyether polyol C (hydroxyl value 360, functionality 3, polyoxypropylene oxide ethylene triol) into a 1L beaker, then add C-225 0.1g, L-580 3g, A33 0.9g, isooctanoic acid Bismuth 0.3g, deionized water 1g, stirred for 30 seconds.

[0029] (2) Modified black material: weigh 20 g of modified black material.

[0030] (3) Free foaming: Pour the weighed modified black material into the combined polyether, then stir for 7 seconds under a mixer with a rotating speed of 4000-4500r / min, pour the foamed liquid into the mold, Cut after 24 hours. That is, the finished high-density slow-rebound sponge is obtained.

[0031] The rebound time is about 4 seconds; the hardening is not obvious in the temperature range of 0-10 ℃, and it has the effect of low temperature resistance; the density is 62...

Embodiment 2

[0033] (1) Polyether polyol A (hydroxyl value 50, functionality 4.5, polyoxypropylene oxide triol) 48g, polyether polyol B (hydroxyl value 65, functionality 4.5, polyoxypropylene triol) 36g , polyether polyol C (hydroxyl value 400, functionality is 3.5, polyoxypropylene oxide ethylene triol) 8g joins in the beaker of 1L, then adds C-225 0.4g, 3.8g L-580, 1.3gA33, iso 0.3 g of bismuth octoate and 1 g of deionized water were stirred for 30 seconds.

[0034] (2) Modified black material: Weigh 40 g of modified black material.

[0035] (3) Free foaming: quickly pour the weighed modified black material into the combined polyether, then stir for 7 seconds under a mixer with a rotating speed of 4000-4500r / min, and pour the foamed liquid into the mold , cut after 24 hours. That is, the finished high-density slow-rebound sponge is obtained.

[0036] The rebound time is about 4.5 seconds; the hardening is not obvious in the temperature range of 0-10 ℃, and it has the effect of low tem...

Embodiment 3

[0038] (1) Add polyether polyol A polyoxypropylene oxide ethylene triol 55g, DEP-560D 30g, DMN-550 15g into a 1L beaker, then add C-2250.1g, 3gL-580, 0.9g A33, iso 0.3 g of bismuth octoate and 1 g of deionized water were stirred for 30 seconds.

[0039] (2) Modified black material: take 60g of modified black material according to the formula.

[0040] (3) Free foaming: quickly pour the weighed modified black material into the combined polyether, then stir for 7 seconds under a mixer with a rotating speed of 4000-4500r / min, and pour the foamed liquid into the mold , cut after 24 hours. That is, the finished high-density slow-rebound sponge is obtained.

[0041] The rebound time is about 4 seconds; the hardening is not obvious in the temperature range of 0-10 ℃, and it has the effect of low temperature resistance; the density is 75g / m 3 , the bearing capacity is twice as high as that of slow rebound sponges in the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com