An environmentally friendly decorative material with high hardness and light specific gravity

A decorative material and light specific gravity technology, applied in the field of building materials, can solve the problems of cumbersome installation and construction, radioactive pollution, excessive formaldehyde content, etc., and achieve the effect of long service life, easy maintenance and light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

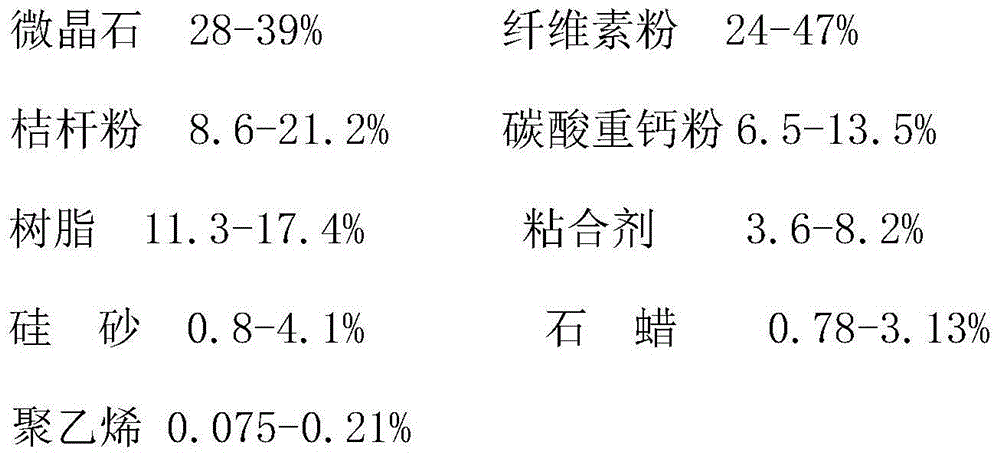

[0014] An environmentally friendly decorative material with high hardness and light specific gravity, its components and weight are:

[0015]

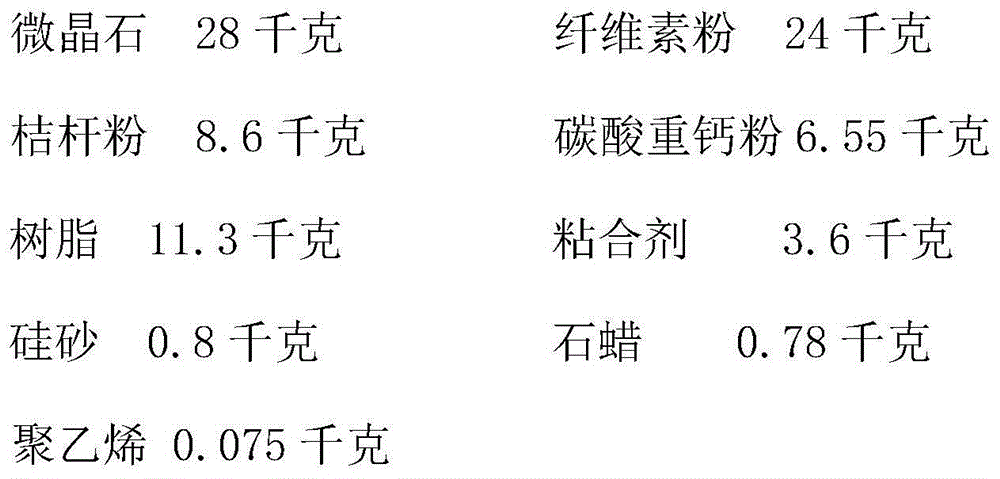

[0016] The above materials are mixed and then extruded at 160°C to obtain 83.705 kg of the present invention.

Embodiment 2

[0018] An environmentally friendly decorative material with high hardness and light specific gravity, its components and weight are:

[0019]

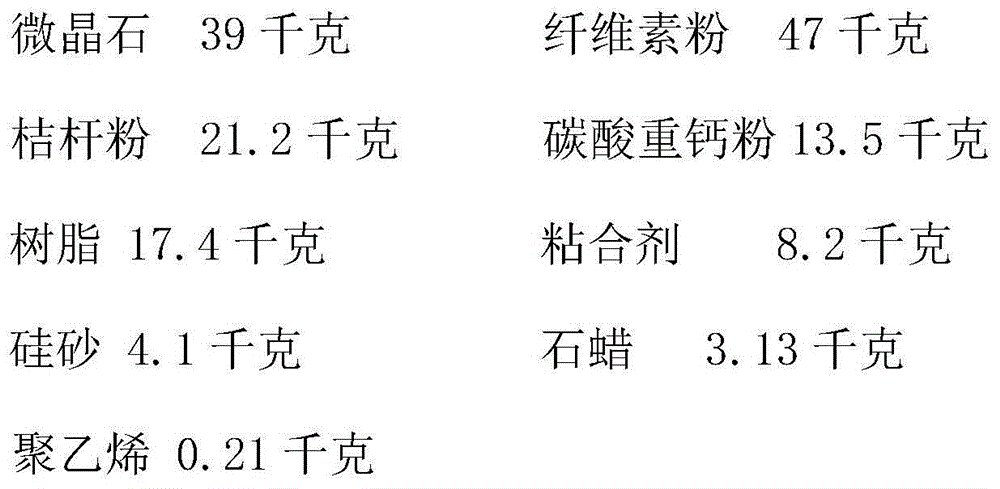

[0020] The above materials are mixed and then extruded at 230°C to obtain 153.74 kg of the present invention.

Embodiment 3

[0022] An environmentally friendly decorative material with high hardness and light specific gravity, its components and weight are:

[0023]

[0024] The above materials are mixed and then extruded at 210°C to obtain 100 kg of the present invention.

[0025] The microcrystalline stone of the present invention has no radioactive hazard, and has strong plasticity. Substituting stone for wood can effectively save wood resources and protect the ecological environment. High density, high hardness, compression resistance, bending resistance, impact resistance and other properties are superior to natural stone, durable and wear-resistant, not easy to be damaged, due to the addition of a certain proportion of cellulose powder, the specific gravity is lighter and more convenient to use. It has the advantages of environmental protection, flame retardant, moisture-proof, insect-proof, no deformation, high hardness, not afraid of water immersion, easy maintenance, high wear resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com