Automatic assembly equipment of precise infusion device

An automatic assembly and infusion set technology, which is applied in the direction of drug devices, other medical devices, and devices introduced into the body, can solve the problems of easy fatigue, easy deformation of operation, and affecting the assembly effect of infusion sets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

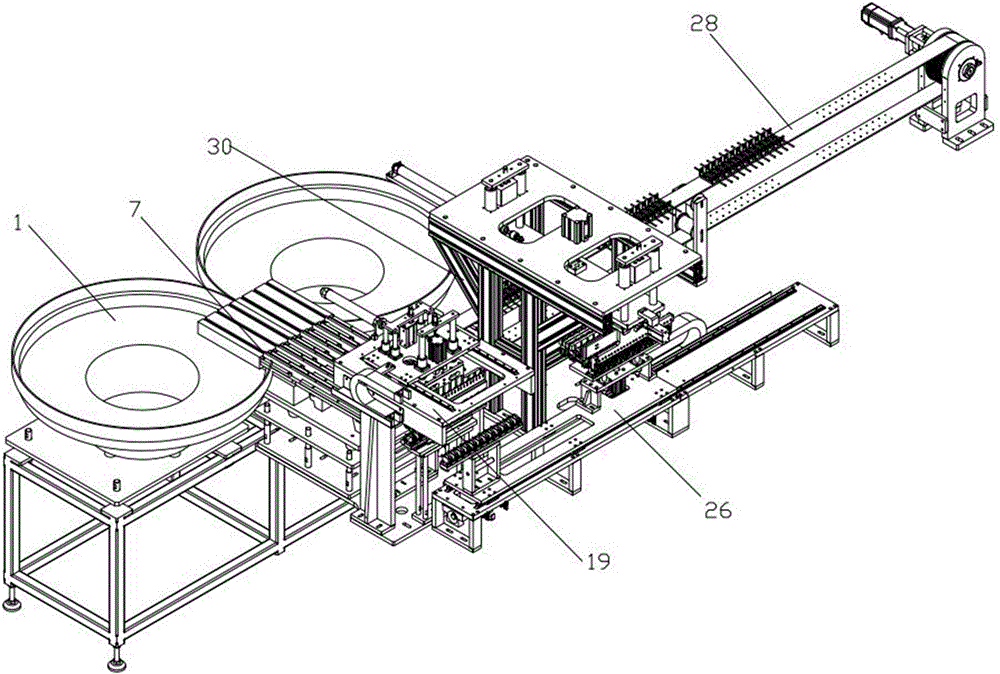

[0066] like Figure 1-13 As shown, the automatic assembly equipment for a precision infusion set provided in this embodiment is mainly composed of a feeding part and an assembly and unloading part, wherein the feeding part includes:

[0067] Two groups of vibrating feeding devices 1;

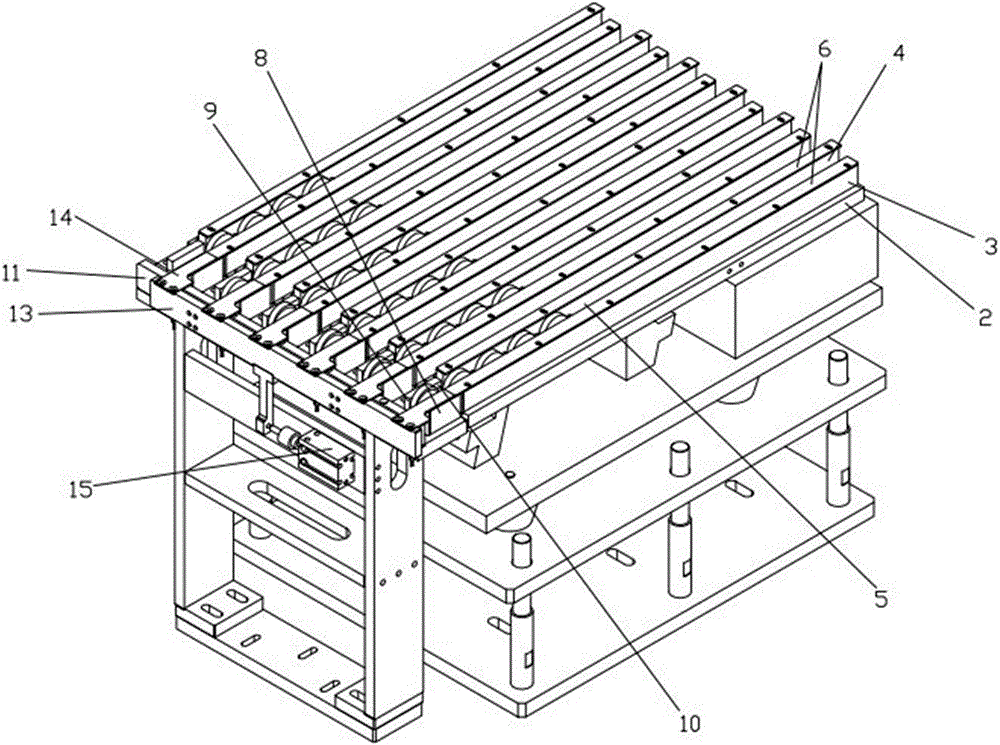

[0068] A discharge and flat delivery device, the discharge and flat delivery device includes a flat delivery base plate 2;

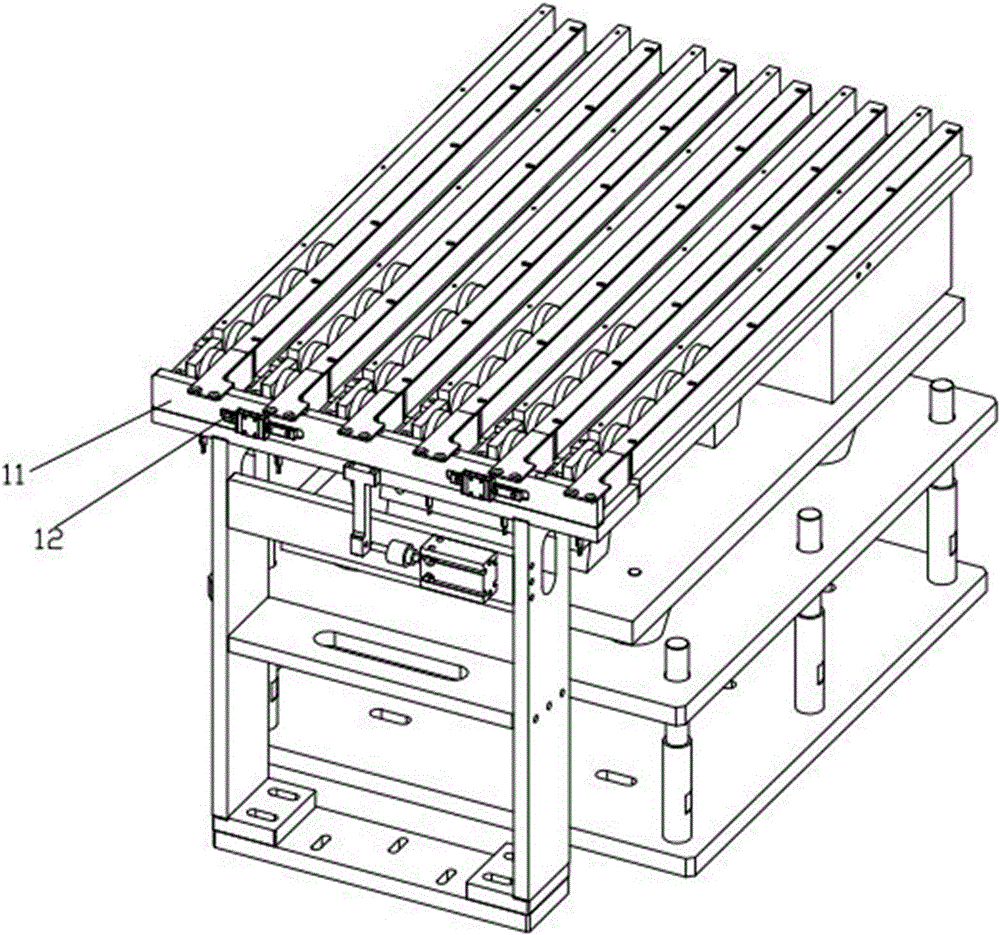

[0069] The first limiting block 3 and the second limiting block 4 arranged at intervals along the horizontal direction of the space on the bottom plate 2, wherein the first limiting block 3 and the second limiting block 4 are distributed alternately, and each An adjacent group of first limit block 3 and second limit block 4 jointly form a flat feed and discharge channel 5 for conveying the filter, and between the first limit block 3 and the second limit block 4 There is a first pressure plate 6 that blocks the opening of the horizontal feeding and discharging channel 5 t...

Embodiment 2

[0083] The automatic assembly equipment of a kind of precision infusion device provided in this embodiment, its general structure is consistent with embodiment 1, as Figure 14 shown, but the translation device 23 described in this embodiment also includes: a group connected to the translation base plate 24, and when the assembly manipulator assembly 33 clamps the filter on the second jig device 21 and the corresponding liquid inlet conduit or When the infusion catheter is assembled, the guiding manipulator assembly 43 acts as a guide for the infusion catheter or the infusion catheter.

[0084] The above-mentioned guide manipulator assembly 43 includes: a fourth support frame 431 fixed to the second slide mechanism 26; a pair of fourth guide rails 432 distributed on the fourth support frame 431 in the vertical direction of space; On the four guide rails 432, the fifth slide table 433 that can reciprocate along the fourth guide rail 432; a seventh cylinder 434 that drives the f...

Embodiment 3

[0087] The automatic assembly equipment of a kind of precision infusion device provided in this embodiment, its general structure is consistent with embodiment 1, as Figure 15 As shown, but in this embodiment, the first support frame 17 is also provided with a first photoelectric switch 44 for detecting whether all twelve first loading fingers 221 have clamped the filter.

[0088] This embodiment provides an automatic assembly device for precision infusion sets, which adds a first photoelectric sensor on the first support frame 17 to detect whether the twelve first feeding fingers 221 have clamped the filter. The switch 44 monitors in real time whether the twelve first loading fingers 221 are working normally through the first photoelectric switch 44, thereby reducing the failure rate of the automatic assembly equipment for precision infusion sets provided in this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com