Asynchronous traction motor flux linkage observation method based on iron loss model

A traction motor and iron loss technology, applied in the field of asynchronous traction motor flux linkage observation based on iron loss model, can solve the problems of large discrete error, not considering the influence of iron loss, parameter-sensitive integral saturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] The method for observing the flux linkage of an asynchronous traction motor based on an iron loss model according to the present invention includes:

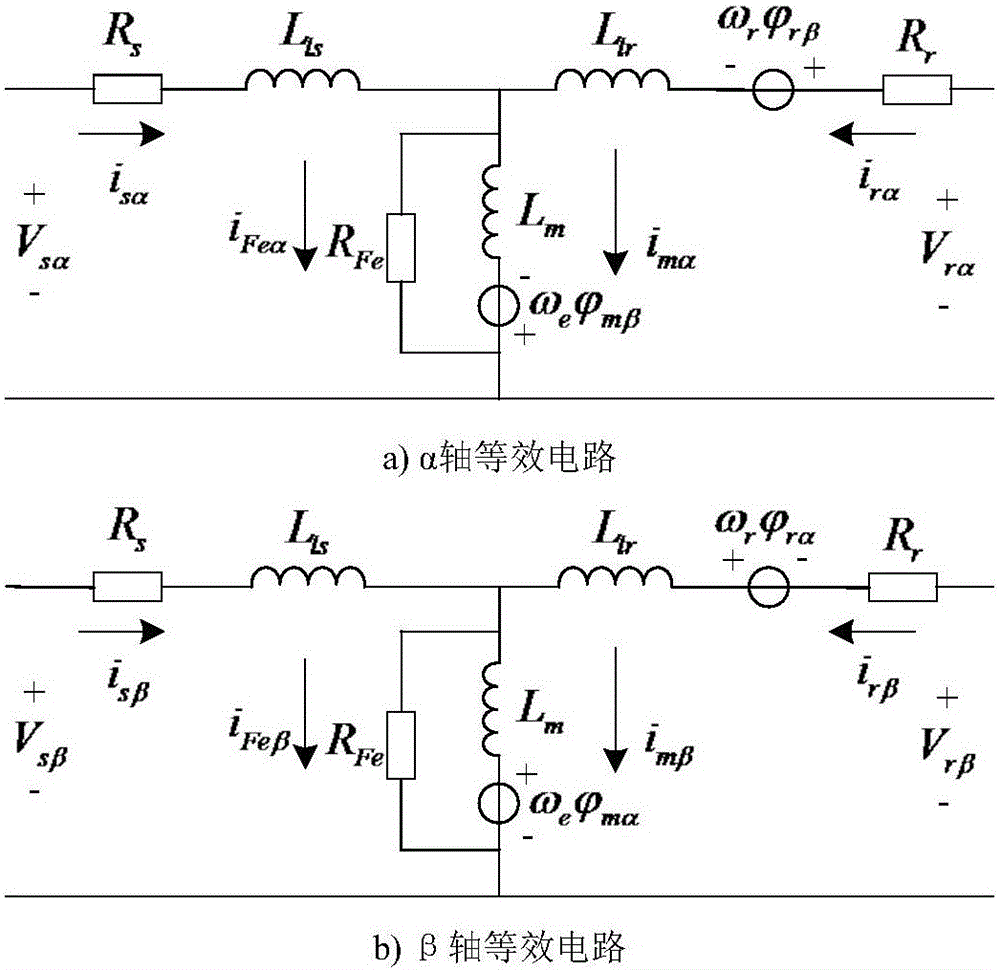

[0035] Based on the equivalent circuit of asynchronous traction motor considering iron loss in two-phase stationary coordinate system, an open-loop state observer considering iron loss is designed;

[0036] Improve the discretization algorithm of the open-loop state observer, obtain an improved open-loop state observer, and solve the problems of divergence of observation results and large observation errors in the medium and high-speed areas of the traditional first-order forward Euler method at low calculation frequencies;

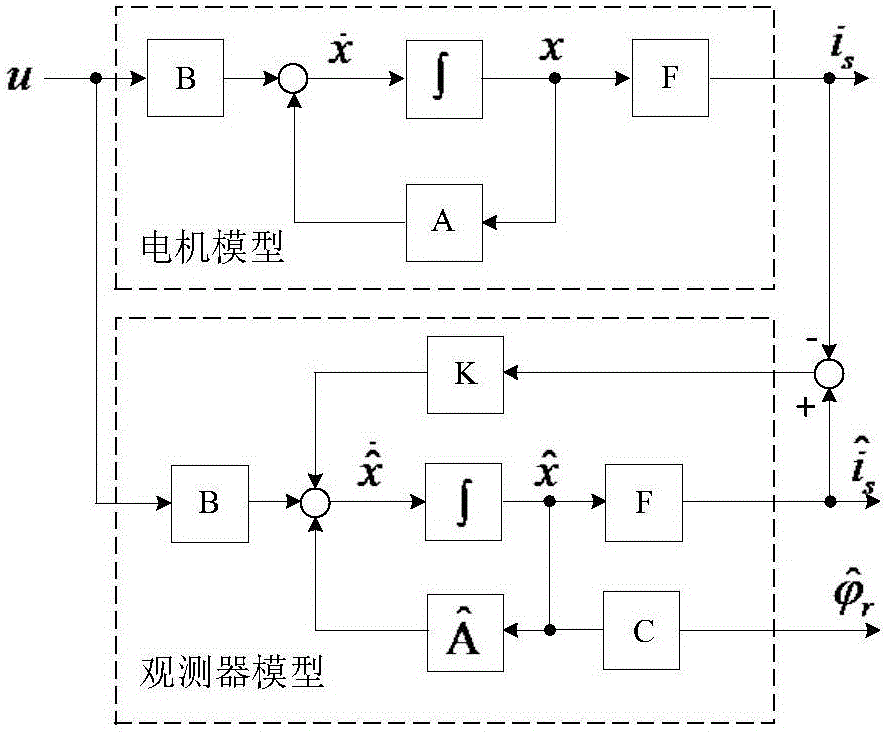

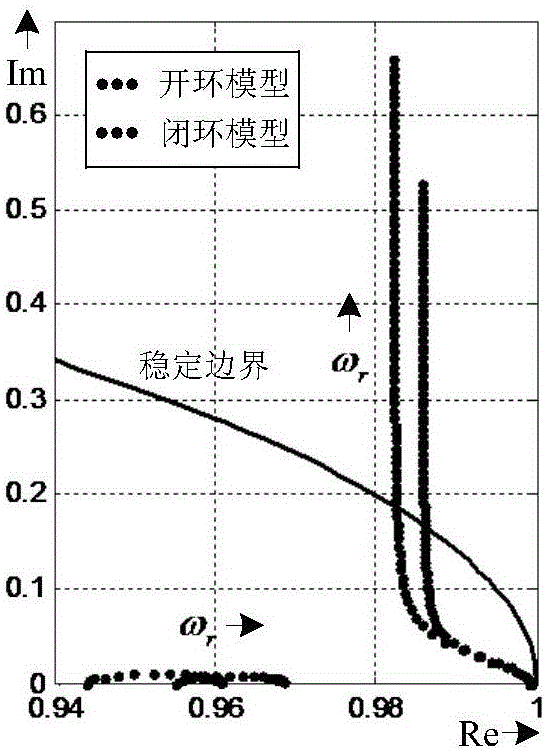

[0037] Taking the stator current observation error as negative feedback, the feedback matrix is designed to configure the poles of the closed-loop state observer to improve the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com