Detection method of steel pipe concrete cavity defect extracted on basis of HHT characteristics

A technology for steel pipe concrete and feature extraction, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problem that errors cannot be visualized and difficult to extract feature modes The main frequency value and other issues, to achieve accurate and intuitive detection results, suppress modal aliasing, and suppress the effects of endpoint effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

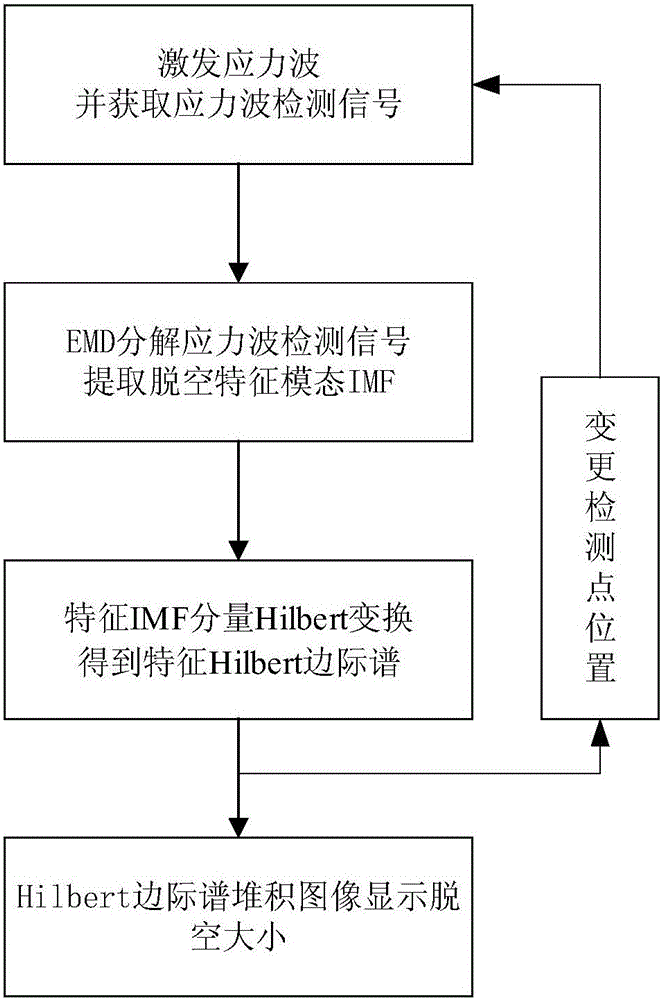

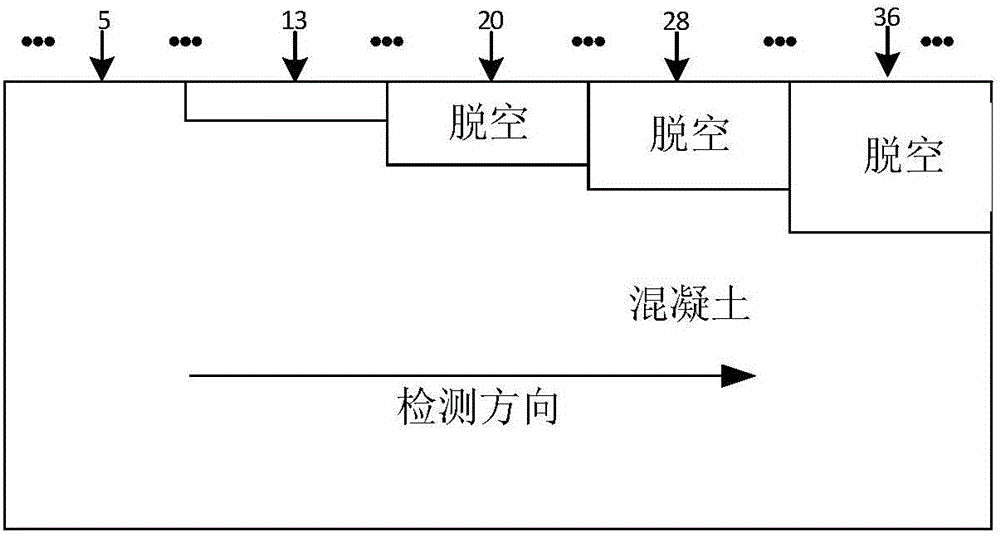

[0024] A method for processing the stress wave detection signal of the concrete filled steel tube void stress wave based on HHT feature extraction provided by the present invention, its flow is as follows figure 1 shown, including the following steps:

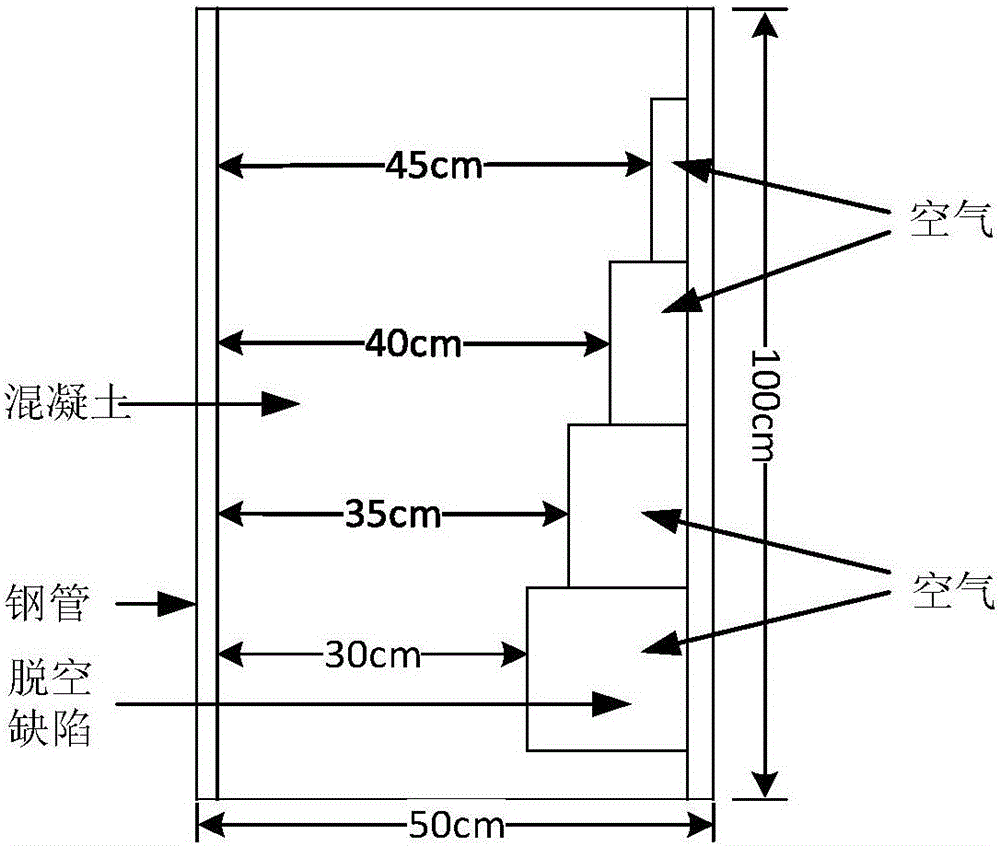

[0025] Step 1: Test the CFST members (see figure 2 ), excite the stress wave on the steel pipe surface and obtain the stress wave detection signal.

[0026] Wherein the preset concrete-filled steel pipe model parameters include: steel pipe diameter 50cm, steel pipe wall thickness 2mm, steel pipe height 100cm, concrete label C35; different degrees of void defects are preset, and the corresponding void diameters are: 0cm, 5cm, 10cm, 15cm, 20cm;

[0027] Wherein the stress wave excites and obtains the specific method of the stress wave detection signal as follows: for the preset steel pipe conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com