Novel contactless nondestructive method of measuring material hardness

A non-contact, non-destructive testing technology, applied in the direction of measuring devices, analyzing materials, using wave/particle radiation for material analysis, etc., to achieve the effect of eliminating damage and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Provide following embodiment in conjunction with content of the present invention:

[0024] (1) Raw material shot blasting

[0025] The selected brand is GCr15 steel, heat treatment process: oil quenching after heating at 840°C for 15 minutes, annealing at 200°C for 120 minutes. After wire cutting, the size is: 30×20×5mm 3 . Using a pneumatic shot peening machine, the sample is subjected to composite shot peening treatment. The shot peening process includes three processes: the first process has a shot peening intensity of 0.50mmA, the second process has a shot peening intensity of 0.30mmA, and the two shot peening The shot medium of the shot peening is unchanged (cast steel shot, diameter is 0.6mm), the shot peening intensity of the third process is 0.15mmA, and the shot medium of the third shot peening is ceramic shot, and the particle size is smaller (0.3mm in diameter).

[0026] (2) Annealing treatment

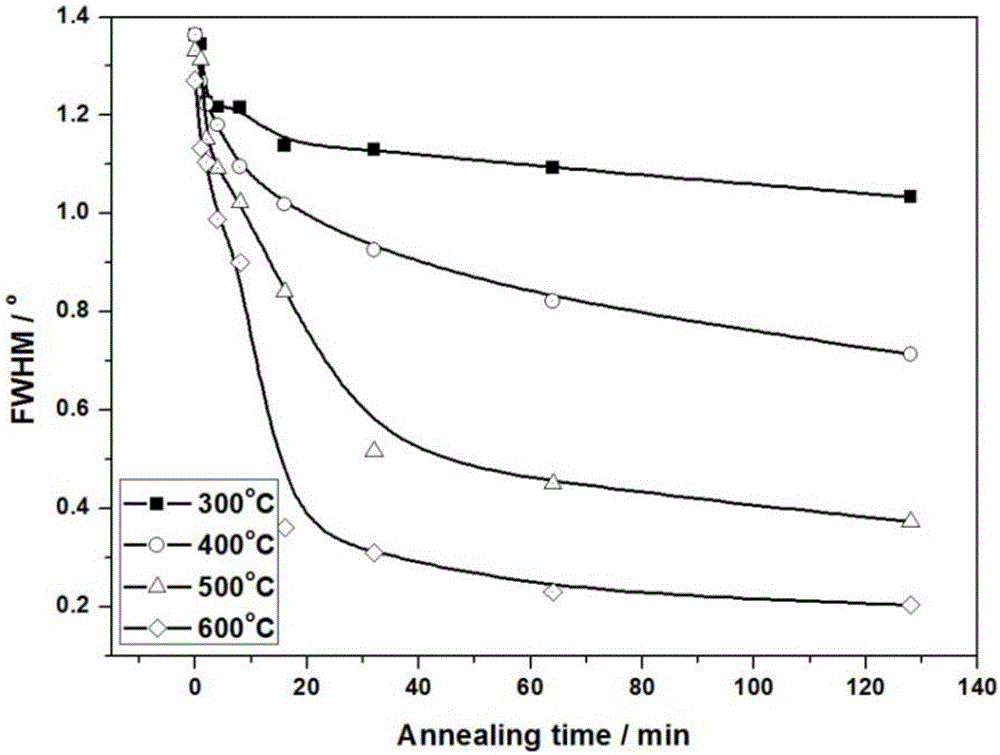

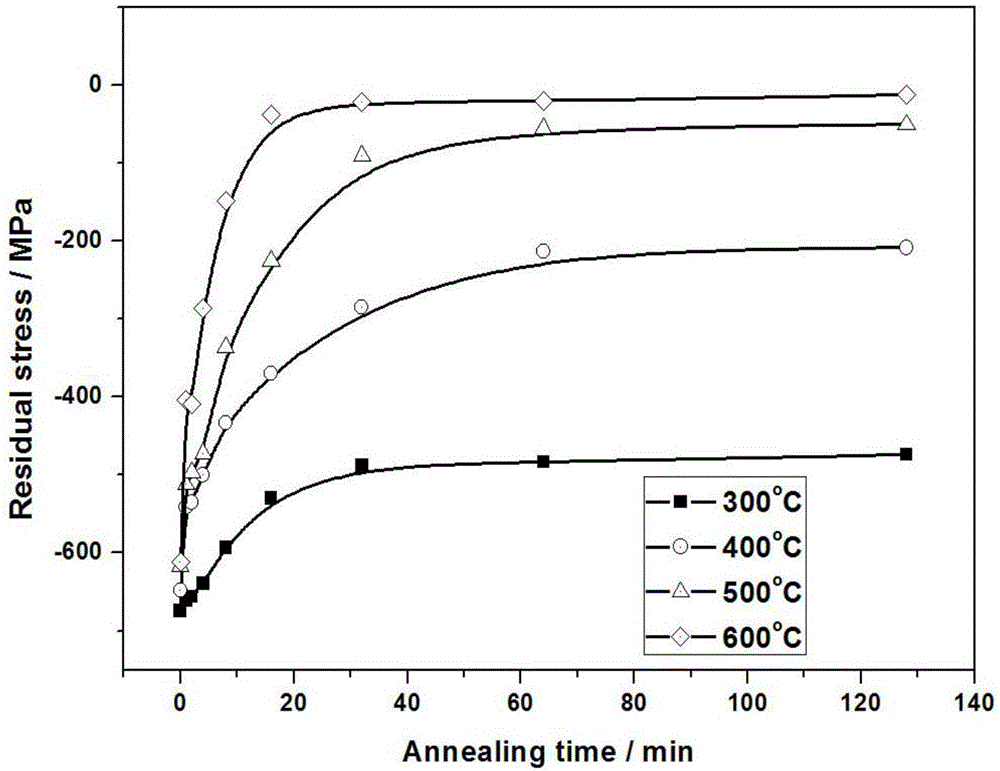

[0027] The samples were annealed at different temperatures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com