Method for refitting common water meter into frost crack prevention water meter

An anti-freeze and water meter technology, applied in the direction of preventing damage to volumetric instruments, etc., can solve problems such as affecting the normal operation of the water meter, the water meter cannot be used normally, and the glass cover of the water meter is frozen and cracked, so as to speed up the recovery of the use function and improve the ice formation sequence. and structure mode, the effect of accelerating rupture and dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

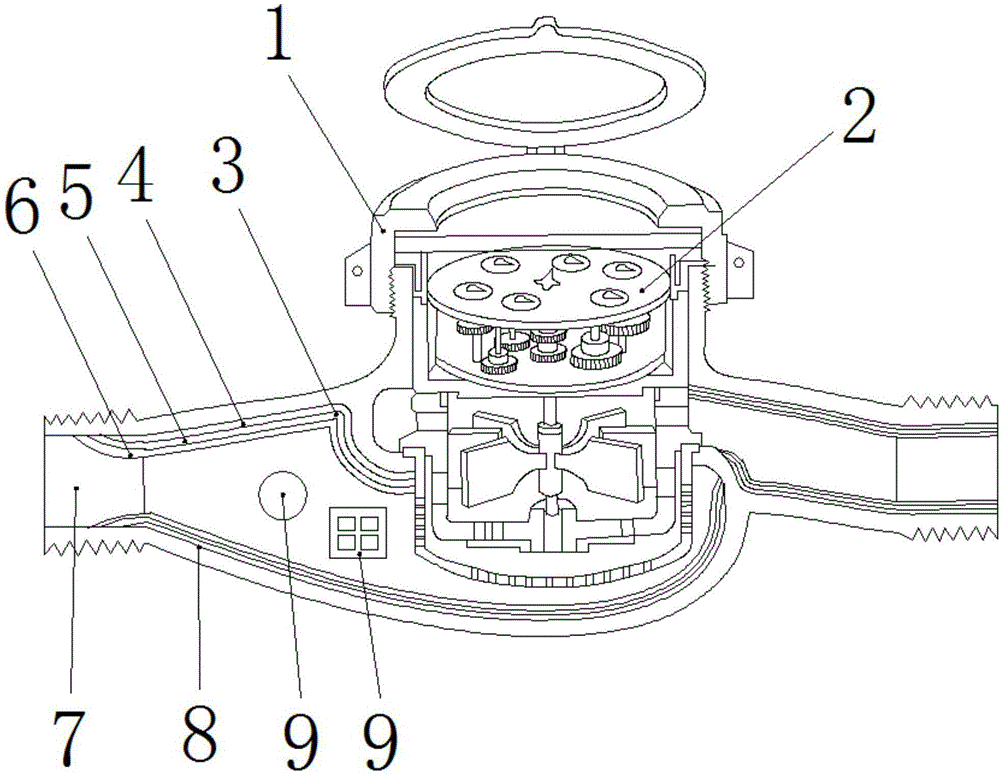

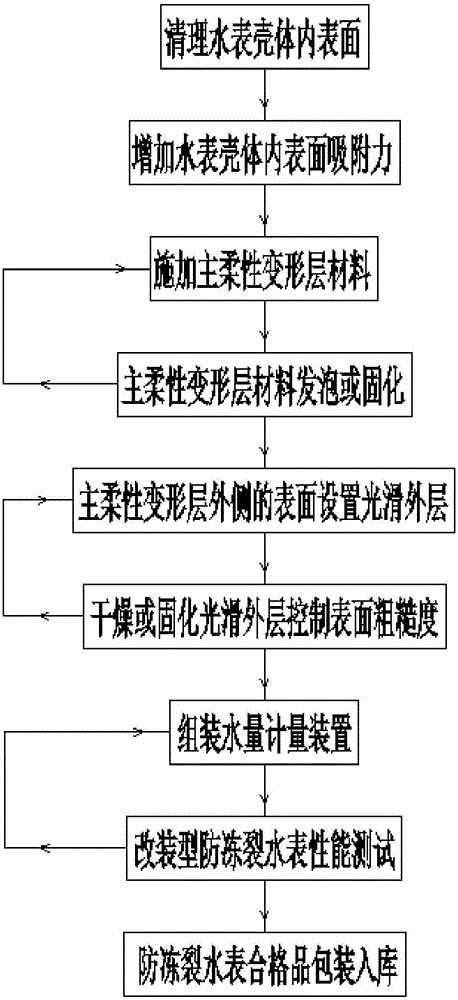

[0037] refer to figure 1 and figure 2 As shown, a method for refitting an ordinary water meter into an anti-freezing and cracking water meter includes a water meter casing, a water metering device, an anti-freezing and cracking tissue and a method for setting the anti-freezing and cracking tissue materials. The water meter casing and the water metering device can constitute a complete conventional For a water meter that is not resistant to frost cracking, the anti-freeze cracking structure is provided with a flexible deformation material, and the flexible deformation material includes a main flexible deformation layer material, a material for changing the surface adsorption force of the water meter casing, and a smooth outer layer that can contact the water in the meter , the antifreeze cracking tissue is closely connected with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com