Pipeline and pipeline system

A pipeline and main pipe technology, applied in the field of pollutant treatment, can solve the problems of limiting the extraction capacity of the extraction tube, the effect of gas injection is not obvious, and the injection tube extends in one direction, so as to facilitate installation and transportation, and improve extraction or injection Efficiency and extraction or injection capacity, effect of increasing extraction or injection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

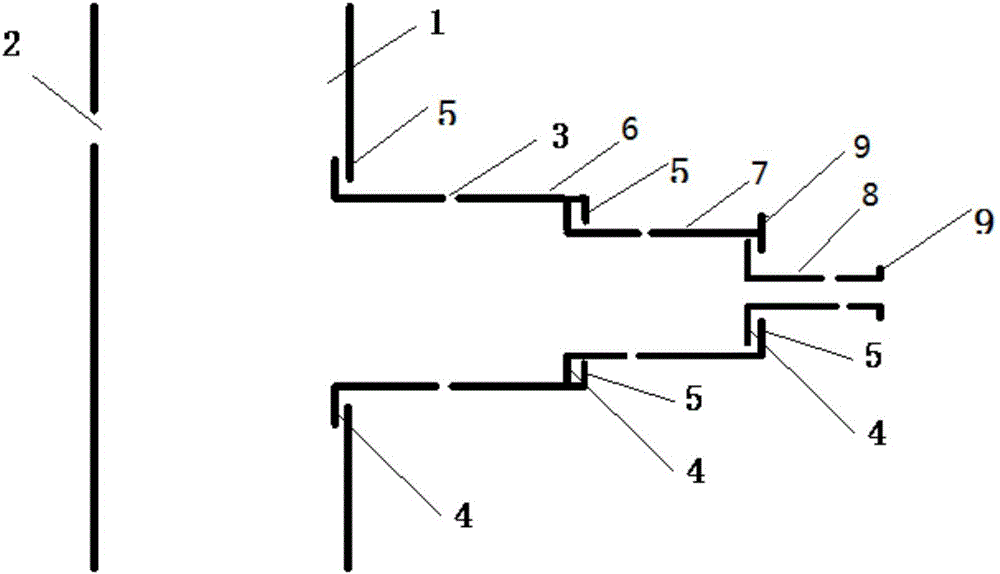

[0047] figure 1 The pipeline provided by this embodiment is shown, including a main pipe 1, a plurality of first air holes 2 are provided on the pipe body of the main pipe 1; and a branch pipe, the branch pipe communicates with the main pipe 1, and the axis of the branch pipe is connected to the The axes of the main pipes 1 form an included angle greater than 0 degrees and less than or equal to 90 degrees, and a plurality of second air holes 3 are arranged on the branch pipes.

[0048] By arranging a branch pipe which communicates with the main pipe 1 and has a number of second air holes 3 arranged at a certain angle, the effective extraction area of the main pipe 1 is extended from the extension direction (vertical direction) of the main pipe 1 in the prior art. , extending to a horizontal direction perpendicular to the extension direction of the main pipe 1 or a direction inclined at a certain angle to the horizontal direction. When the pipeline is used for gas phase extra...

Embodiment 2

[0074] This embodiment provides a gas injection pipeline. The structure of the pipeline is the same as that described in Embodiment 1. In this embodiment, the pipeline is used for gas injection, and the injected gas passes through the main pipe and several nested connections in sequence. The circular tube makes the gas to be injected move in a direction perpendicular to the horizontal direction of the main pipe or inclined at a certain angle to the horizontal direction, and finally enters the underground soil through the second air hole on the composite casing. Therefore, the overall injection area of the pipeline is effectively increased, and the injection efficiency of the gas is improved.

[0075] Specifically, the injected gas can be water vapor. When the high-temperature water vapor is injected into the ground, the volatile organic pollutants in the soil can be changed into a gas phase, and then the gas phase pollutants can be extracted to remove the pollutants. the goa...

Embodiment 3

[0078] This embodiment provides a pipeline system, including a pipeline, and a main pipe lifting device for raising or lowering the main pipe. Through the main pipe lifting device, the extraction pipeline or injection pipeline involved in embodiment 1 or embodiment 2 can be accurately parked at a specific position.

[0079] Specifically, the main pipe lifting device is connected to the pipeline. When extraction or gas injection operation is required, the injection pipeline or extraction pipeline involved in embodiment 1 or embodiment 2 is connected to the main pipe lifting device. Under the action, it extends down along the soil, and when it reaches a specific position, the distance monitoring device sends a signal to stop the main pipe from moving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com