Direction adjusting structure for hygiene product production equipment

A technology for the production of equipment and sanitary products, which is applied in the direction of mechanical equipment, belts/chains/gears, transmission devices, etc. It can solve the problems of inability to meet high-speed and stable transmission of items, high manufacturing costs, and large cam volume, and achieve good mechanical properties. , low manufacturing cost and high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

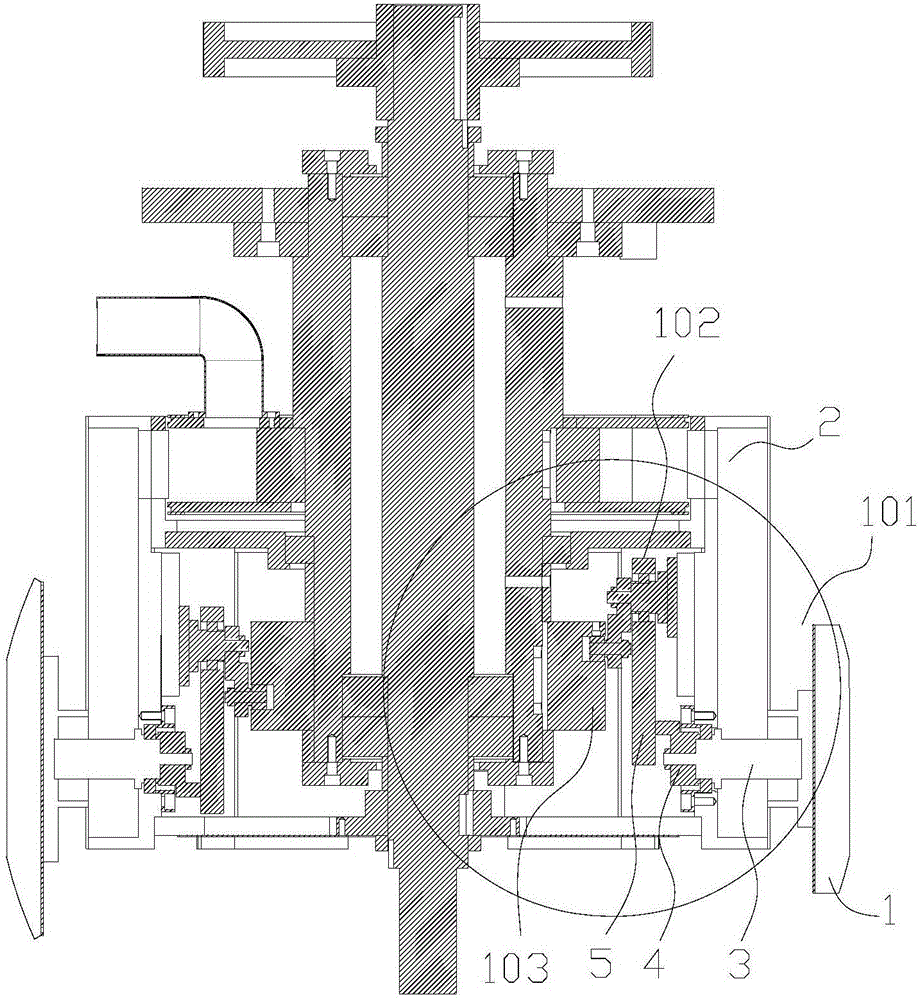

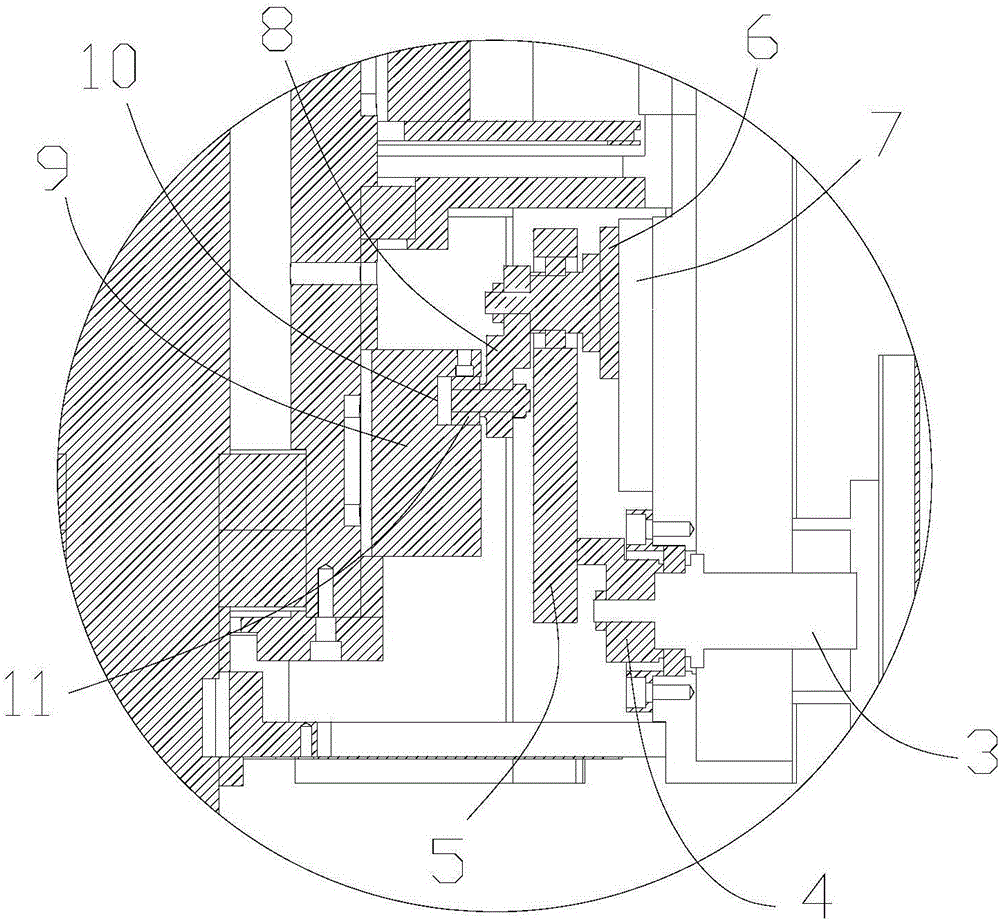

[0019] see Figures 1 to 2 , a direction adjustment structure for sanitary product production equipment, including a rotating part 101, a direction changing part 102 and a guiding part 103.

[0020] Wherein, the rotating part 101 rotates periodically under the action of the guiding part 103 , which has a rotatable adsorption part 1 , a transmission case 2 , and a pivot 3 perpendicular to the rotation plane of the adsorption part 1 .

[0021] Several suction holes leading to the interior of the adsorbent 1 are opened on the surface of the adsorbent 1 , and the transmission case 2 and the adsorbent 1 are hollow and communicate with each other. The pivot 3 runs through the transmission box 2 and is connected with the absorber 1 . The manner of the adsorbing member is not limited to vacuuming, and the manner of electrostatic attraction can also be used. According to the position of the cam guide 11 , the adsorption member 1 periodically rotates along the direction-changing cam g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com