A connection system and construction method of combined shear wall

A shear wall and system technology, applied to walls, building components, earthquake resistance, etc., can solve problems such as hard to repair, spalling, concrete cracking, etc., and achieve the effects of reducing construction waiting time, saving construction period, and facilitating construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

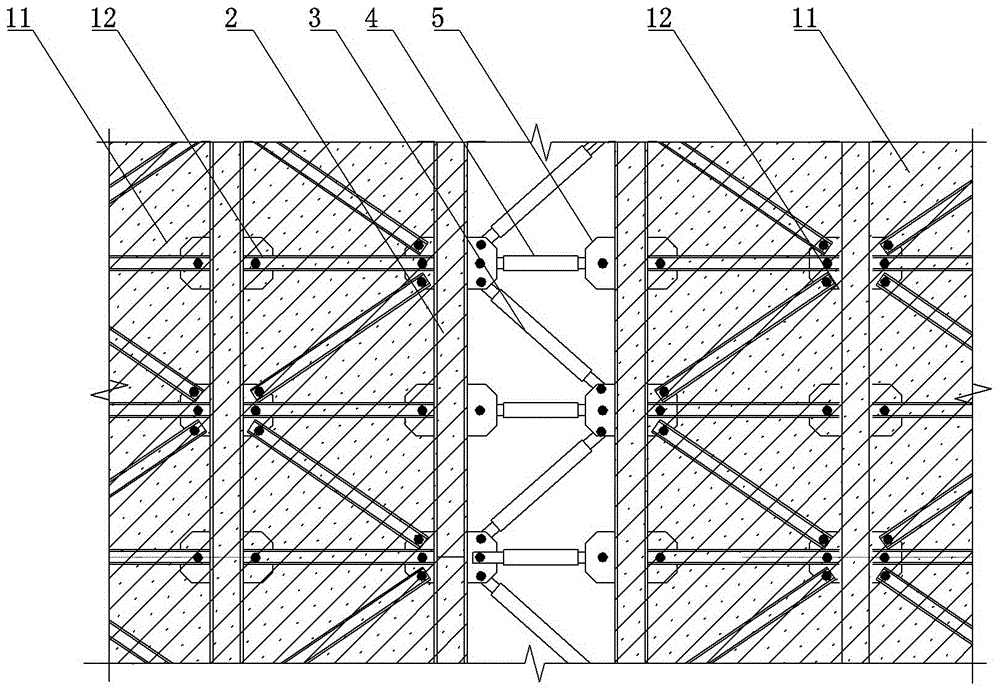

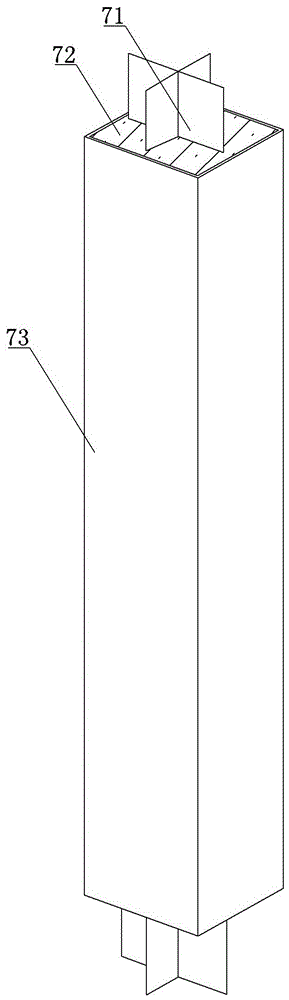

[0049] Example as figure 1 , figure 2 , image 3 , Figure 4 Shown: a connection system for a composite shear wall, including a shear wall limb 11 with a built-in steel truss 12, a steel bone column 2, and an exposed web member. The connecting plate 5 is fixedly connected along the length direction of the steel column 2, and the exposed web and the built-in steel truss 12 are respectively hinged with the connecting plate 5, and the steel column 2, the exposed web and the built-in steel truss 12 are combined to form an integral steel frame. For the truss, the steel bone column 2 serves as the chord of the overall steel truss, and the exposed web serves as the web of the overall steel truss. The steel column 2 is arranged inside the shear wall pier 11 as an outer frame column. The connecting plate 5 can be welded with the steel frame column 2, or can be bolted with the steel frame column 2, etc. In this embodiment, the connecting plate 5 is welded with the steel frame colum...

Embodiment 2

[0057] The applicant also invented another new type of safety telescopic rod for the connection system of combined limb shear walls. The safety telescopic rod includes a hollow sleeve rod 82 and a threaded rod 83 made of high-strength structural steel. Such as Figure 5 As shown, the right end of the hollow sleeve rod 82 is welded with a connector 61, the hollow sleeve rod 82 is formed with a hollow cavity arranged axially along the hollow sleeve rod 82, and the left side wall of the hollow cavity is provided with a The internal thread of the hollow cavity is smooth on the right side. The threaded rod 83 is screwed into the hollow cavity inside the hollow sleeve rod 82 . A piston 84 is mounted on the right end of the threaded rod 83, and the piston 84 is slidingly engaged with the left side wall of the hollow cavity. The piston 84 and the hollow cavity form a closed pressure chamber 85 , the pressure chamber 85 is filled with hydraulic oil, and the pressure chamber 85 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com