Sand barrier structure and preparation method thereof

A sand barrier and sand layer technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as short warranty period, impact on environmental protection, poor effect, etc., achieve rapid infiltration and evaporation, reduce evaporation, and improve setting The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

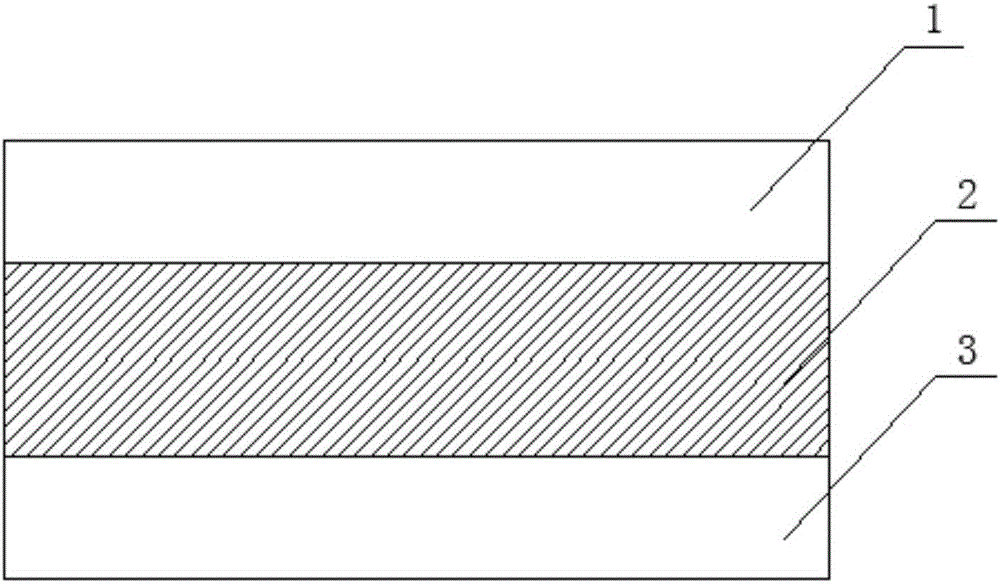

[0034] like figure 1 As shown, a sand barrier structure includes a first sand layer 1 arranged on the outer surface, a second sand layer 3 arranged at the bottom, and a clay layer 2 between the first sand layer 1 and the second sand layer 3,

[0035] The thickness of the first sand layer 1 is 30cm,

[0036] The thickness of clay layer 2 is 20cm,

[0037] The first sand layer 1 is aeolian sandy soil, and its texture belongs to sandy soil in the international soil classification system.

[0038] The second sand layer 3 is aeolian sandy soil, and its texture belongs to sandy soil in the international soil classification system.

[0039] The clay in the clay layer 2 is a loamy soil with a tighter structure than the sandy soil in the International Soil Classification.

[0040] Further, the width of the first sand layer 1 is 1 meter, and the width of the clay layer 2 is 1 meter.

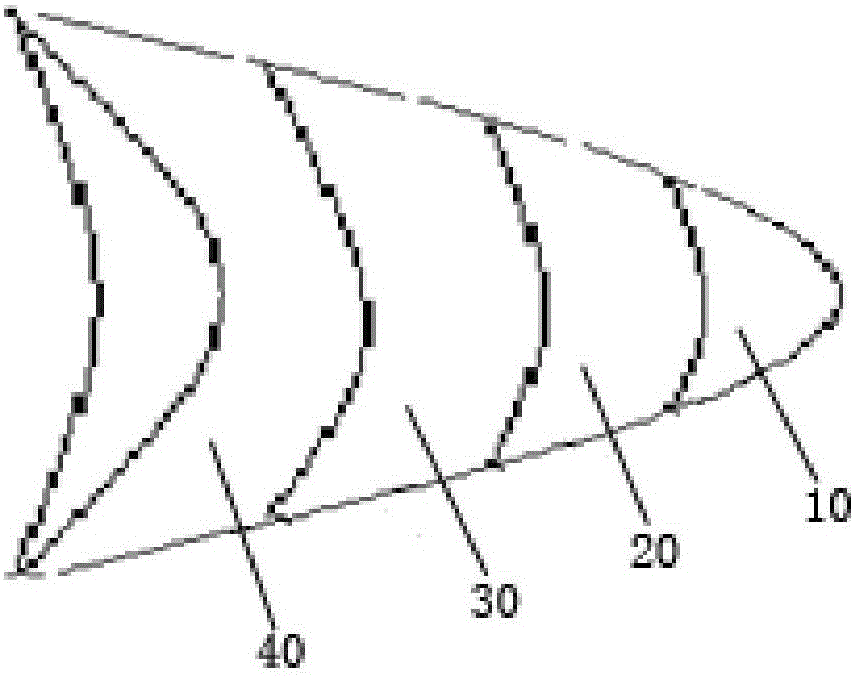

[0041] like figure 2 Shown, a kind of preparation method of sand barrier structure comprises the ...

specific Embodiment 2

[0049] It is roughly the same as the specific embodiment 1, the only difference is that the texture of the clay layer 2 is clay, and the clay is a clay loam soil with a tighter structure than the sandy soil in the international soil classification system.

specific Embodiment 3

[0050] It is roughly the same as the specific embodiment 1, except that the texture of the clay layer 2 is clay, and the clay is a clay with a tighter structure than the sandy soil in the international soil classification system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com