A spinning tube and its manufacturing method

A manufacturing method, technology of spinning tube, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problem that the strength and wear resistance cannot meet the production requirements, affect the stability of production order, and the friction of spinning tube Large and other problems, to achieve the effect of reducing the friction coefficient, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

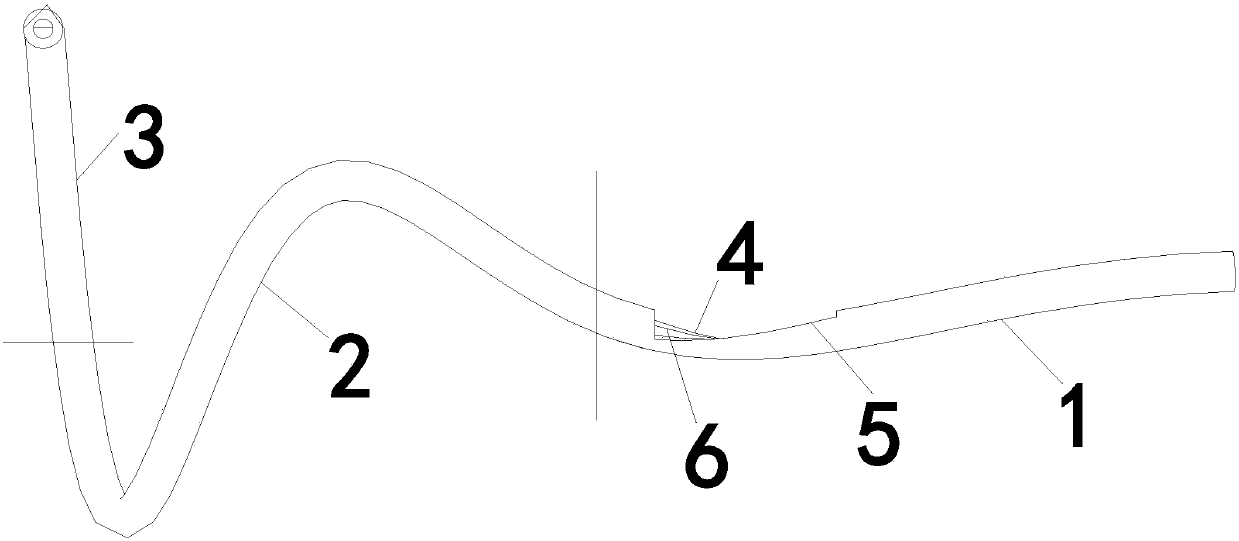

[0035] Such as figure 1 As shown, a spinning tube includes the following components by mass ratio: C: 0.06, Mn: 0.30, P≤0.02, S≤0.01, Si: 0.20, Cr: 7.50, Mo: 0.90, V: 0.18, Nb : 0.06, N: 0.03, Ni: ≤0.10, Cu: 0.10~0.30, W: ≤0.0004, Co: ≤0.001, B: 0.01~0.05, TiC≤0.0006, and the balance is iron.

[0036]The spinning tube in this embodiment includes an introduction section, a deformation section and a stabilization section. Grooves are made on the non-stressed side of the introduction section 300-500 mm, and a plasma arc driven by direct current is used as a heat source to melt tungsten carbide powder and spray it on the A tungsten carbide coating is formed on the stressed side; the thickness of the tungsten carbide coating is 0.05mm; TiC is nanoscale powder.

[0037] The manufacturing method of above-mentioned spinneret tube, comprises the following steps:

[0038] (1) Preparation of raw materials: The following components are taken according to the mass ratio: C: 0.06, Mn: 0.3...

Embodiment 2

[0050] A spinneret, comprising the following components by mass ratio: C: 0.07, Mn: 0.4, P≤0.02, S≤0.01, Si: 0.35, Cr: 820, Mo: 1.00, V: 0.20, Nb: 0.07, N: 0.05, Ni: ≤0.10, Cu: 0.10-0.30, W: ≤0.0004, Co: ≤0.001, B: 0.01-0.05, TiC ≤0.0006, and the balance is iron.

[0051] The spinneret in this embodiment includes an introduction section, a deformation section and a stabilization section. Grooves are made on the non-stressed side of the 400 mm area of the introduction section, and a plasma arc driven by direct current is used as a heat source to melt tungsten carbide powder and spray it at a high speed until the force is applied. The tungsten carbide coating is formed on the side; the thickness of the tungsten carbide coating is 0.07mm; TiC is nano-scale powder.

[0052] The manufacturing method of above-mentioned spinneret tube, comprises the following steps:

[0053] (1) Preparation of raw materials: The following components are taken according to the mass ratio: C: 0.07, ...

Embodiment 3

[0065] A spinneret, comprising the following components by mass ratio: C: 0.10, Mn: 0.60, P≤0.02, S≤0.01, Si: 0.50, Cr: 9.20, Mo: 1.15, V: 0.25, Nb: 0.10, N: 0.07, Ni: ≤ 0.10, Cu: 0.10-0.30, W: ≤ 0.0004, Co: ≤ 0.001, B: 0.01-0.05, TiC ≤ 0.0006, and the balance is iron.

[0066] The spinneret of this embodiment includes an introduction section, a deformation section and a stabilization section. Grooves are made on the non-stressed side of the 500 mm area of the introduction section, and a plasma arc driven by direct current is used as a heat source to melt tungsten carbide powder and spray it on the stressed side at high speed to form Tungsten carbide coating; the thickness of tungsten carbide coating is 0.09mm; TiC is nano-scale powder.

[0067] The manufacturing method of above-mentioned spinneret tube, comprises the following steps:

[0068] (1) Preparation of raw materials: C: 0.10, Mn: 0.60, P≤0.02, S≤0.01, Si: 0.50, Cr: 9.20, Mo: 1.15, V: 0.25, Nb: 0.10, N: 0.07, Ni: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com