3D cell culture system

A cell culture, 3D technology, applied in tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., can solve problems such as adverse effects, time-consuming and laborious, cell contamination, etc., to save labor costs, unmanned Chemical operation, avoid the effect of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

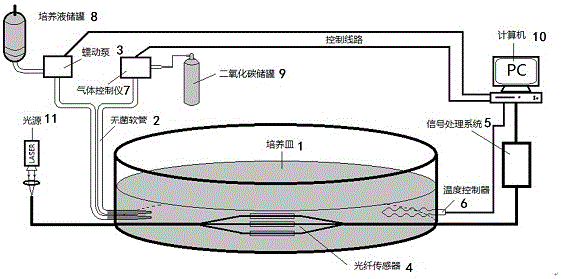

[0028] In this example, see figure 1 , the 3D cell culture system includes a cell culture dish (1), a sterile hose (2), a peristaltic pump (3), an optical fiber sensor (4), a signal processing system (5), a temperature controller (6), Gas controller (7), cell culture solution storage tank (8), carbon dioxide gas storage tank (9), computer and supporting control software (10) and light source (11). It is characterized in that two sterile hoses (2) are connected to the bottom of the cell culture dish (1), a temperature controller (6) is inserted and an optical fiber sensor (4) is connected, and the two sterile hoses ( 2) Through the peristaltic pump (3) and the gas controller (7), connect the cell culture solution storage tank (8) and the carbon dioxide gas storage tank (9) to deliver the cell culture solution and gas to the cell culture dish (1). carbon dioxide gas; one end of the optical fiber sensor (4) is connected to the light source (11), and the other end is connected to...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, especially in that:

[0033] The structure of the cell culture dish (1) is a general-purpose petri dish for cell experiments or a cell culture plate composed of multiple petri dishes. There are several interfaces at the bottom, and a bundle of optical fiber sensors (4) are used to detect the Temperature, pH value and refractive index; two sterile hoses (2) are connected to add culture medium and carbon dioxide to the cell culture dish through peristaltic pump (3) and gas controller (7); add temperature control The device (6) can regulate the internal temperature of the culture medium.

[0034] The structure of the optical fiber sensor (4) is divided into two optical fiber transmission sections and a sensing section. One of the optical fiber transmission sections receives the injection of standard laser light from the light source (11). When the standard laser light is transmitted to the sensing section, it is affec...

Embodiment 3

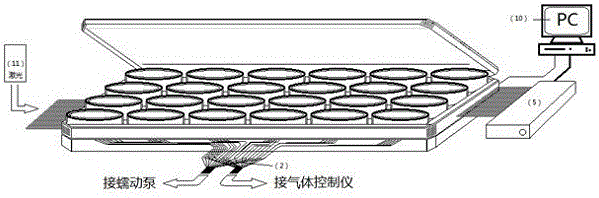

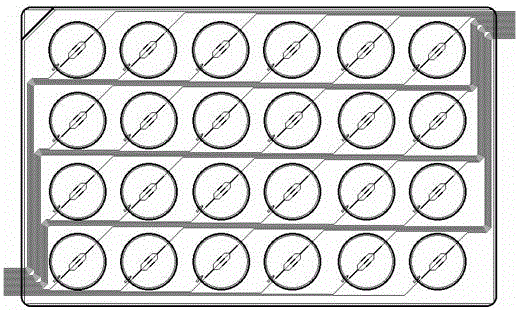

[0037] In this example, the system can be combined with a multi-well cell culture plate ( figure 2 , image 3 ), also known as a multi-dish system, each culture well or dish is independently installed with the same optical fiber sensor (4), sterile soft (2) tube, temperature controller (6) and other supporting equipment as in the embodiment , and reasonably arrange the lines of optical fibers, hoses and wires on the culture plate ( image 3 ). All culture dishes in the whole system can work simultaneously and independently, and each well or dish can achieve different culture conditions, which are individually controlled by the computer to meet the needs of different cell experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com