Gap filling adhesive for maintaining asphalt concrete pavement and preparing method

A technology for asphalt concrete and joint filling glue, applied in the direction of asphalt material adhesive, adhesive, adhesive type, etc., can solve the problems of low temperature brittleness, poor fluidity, difficult construction and high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

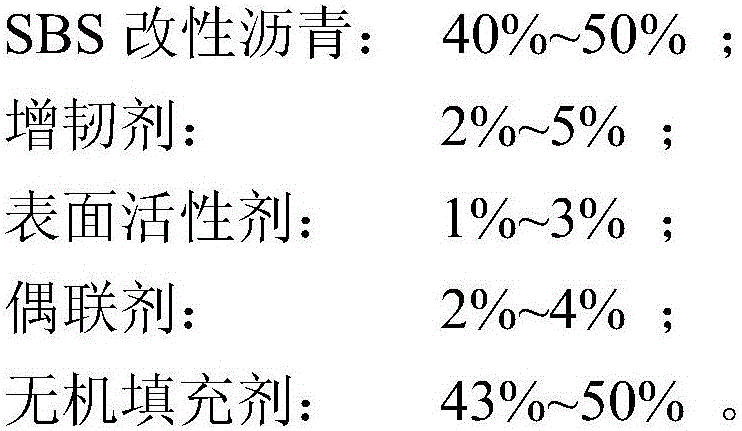

Embodiment 1

[0031] The proportioning raw materials are: SBS modified asphalt: 50%; toughening agent: 2%; surfactant: 3%, coupling agent: 2%; filler: 43%.

[0032] 1) Pump 500kg of liquid SBS modified asphalt at 150~180℃ into a 1200L dispersion tank,

[0033] 2) Open the dispersion slurry and add 20kg of toughening agent (liquid polysulfide rubber JLY-124) at the same time, and then adjust the speed to high speed (600 rpm) for 30 minutes of heat preservation and dispersion.

[0034] 3) Then add cationic surfactant (cetyltrimethylammonium chloride 1631) 30kg, silane coupling agent (γ-aminopropyltriethoxysilane KH550) 20kg and filler nano calcium carbonate 430kg, At 150-180°C; continue to disperse at 600 rpm for 30 minutes to obtain a viscous and uniform black liquid, discharge, cool and solidify, and pack for storage.

Embodiment 2

[0036] The proportioning raw materials are: SBS modified asphalt: 40%; toughening agent: 5%; surfactant: 1%, coupling agent: 4%; filler: 50%. .

[0037] 1) Pump 400kg of liquid SBS modified asphalt at 150-180°C into a 1200L dispersion tank,

[0038] 2) Open the dispersion slurry and add 50kg of toughening agent (liquid polysulfide rubber JLY-124) at the same time, and then adjust the speed to high speed (800 rpm) for 60 minutes of heat preservation and dispersion.

[0039] 3) Add cationic surfactant (hexadecyltrimethylammonium chloride 1631) 10kg, silane coupling agent (γ-aminopropyltriethoxysilane KH550) 40kg and filler nano-calcium carbonate 500kg in sequence, At 150-180°C; continue to disperse at 800 rpm for 30 minutes to obtain a viscous and uniform black liquid, discharge, cool and solidify, and pack for storage.

Embodiment 3

[0041] The proportioning raw materials are: SBS modified asphalt: 45%; toughening agent: 3.5%; surfactant: 2%, coupling agent: 3%; filler: 46.5%.

[0042] 1) Put 20kg of cationic surfactant (hexadecyltrimethylammonium chloride 1631), 30kg of silane coupling agent (γ-aminopropyltriethoxysilane KH550), and 465kg of inorganic filler nano-calcium carbonate into the modified Surfactant fillers can be obtained by performing high-speed kneading modification pretreatment at 100-120°C in permanent equipment (equipment for modification of inorganic fillers, which can be purchased in the market);

[0043] 2) Pump 450kg of liquid SBS modified asphalt at 150-180°C into a 1200L dispersion tank,

[0044] 3) Open the dispersion slurry and add 35kg of toughening agent (liquid polysulfide rubber JLY-124) at the same time, and then adjust the speed to high speed (700 rpm) for 45 minutes of heat preservation and dispersion.

[0045] 4) Add 515kg of the above-mentioned surface-active filler, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com