Hydrophobic sulfydryl-modified silicone rubber and preparation method thereof

A modified silicon and hydrophilic technology, applied in the field of surface modified vulcanized silicone rubber and its preparation, can solve the problems of low surface free energy of silicone rubber, and achieve the effects of high hydrophilicity, simple process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

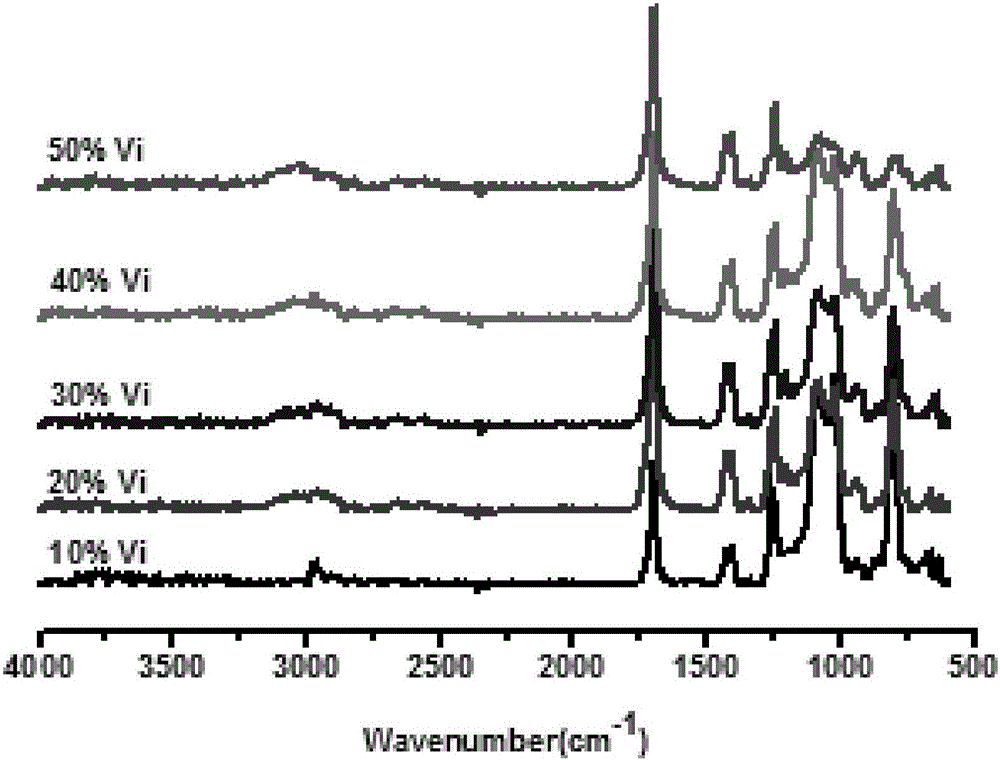

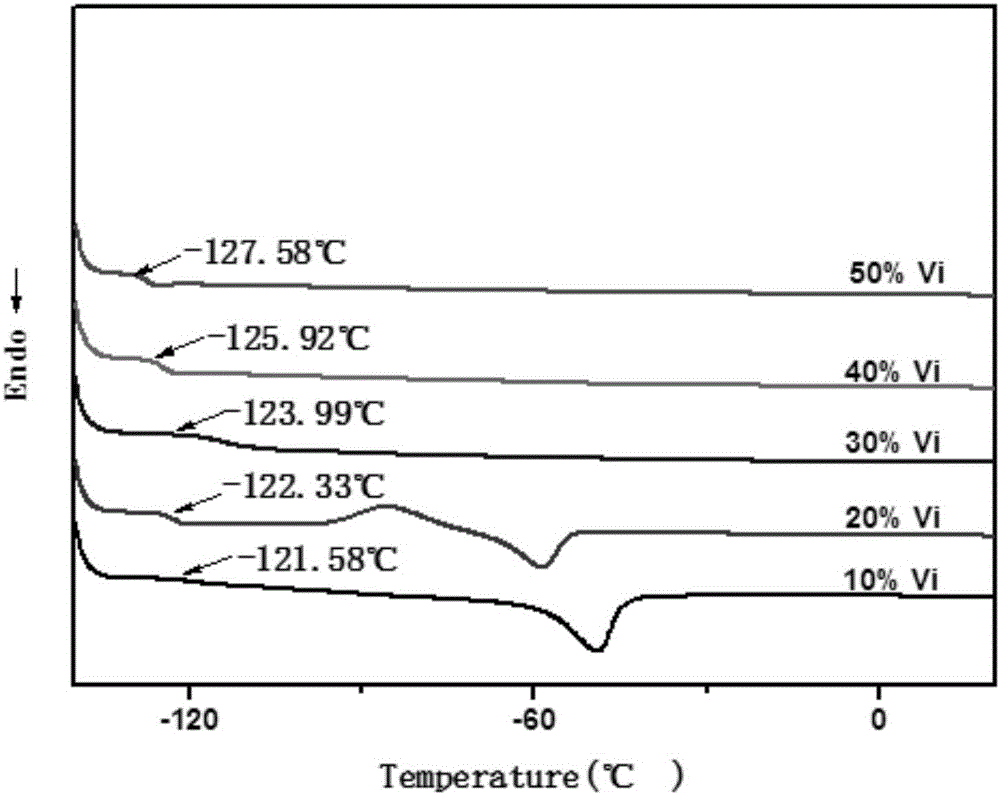

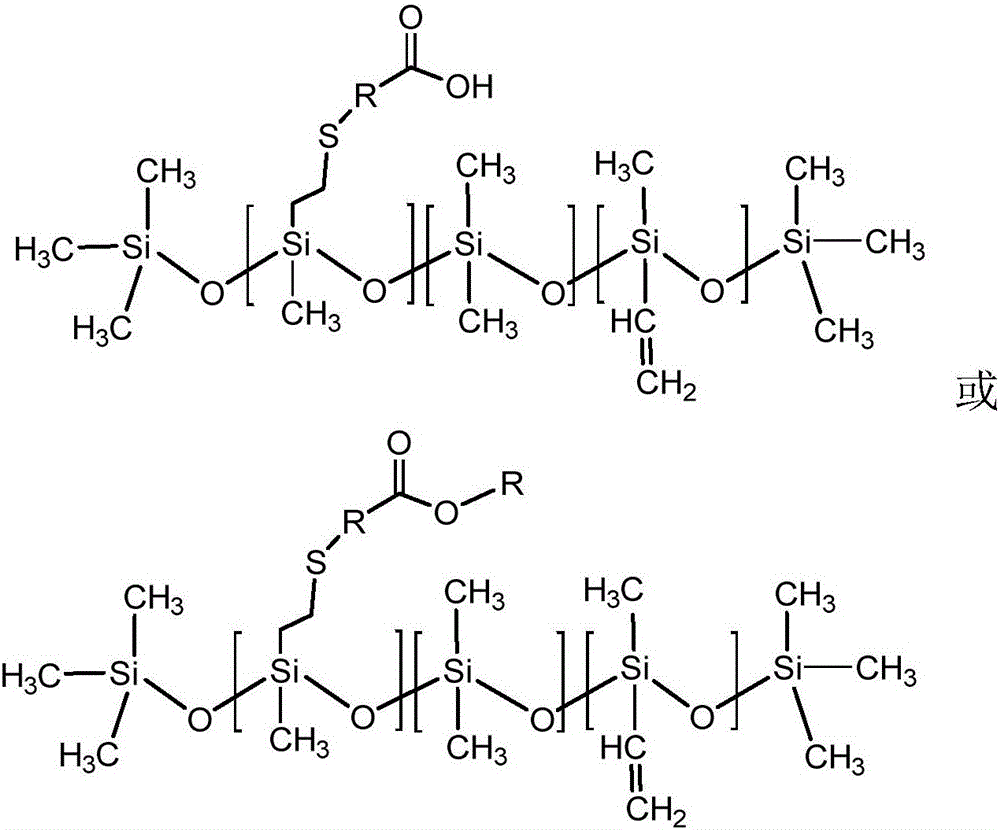

[0021] Get 0.8g tetramethylammonium hydroxide and 20g octamethylcyclotetrasiloxane, vacuum dehydrate at 50°C for 1h, then raise the temperature to 80°C for 1h, and prepare tetramethylammonium hydroxide silicon alkoxide (catalyst base glue). Then take 80g octamethylcyclotetrasiloxane (D 4 ), 20g tetramethyltetravinylcyclotetrasiloxane (V 4 ) and 0.1g of tetramethylhexasiloxane, dehydrated at 40°C for 3h under vacuum, then blown nitrogen gas, added 0.6g of tetramethylammonium hydroxide silicon alkoxide (alkali glue), and raised the temperature to 110°C, Reaction under normal pressure for 3h. After the reaction, the temperature was raised to 160°C, and the small molecules in the product were removed under vacuum for 3 hours, and then cooled to room temperature to obtain a methyl vinyl silicone rubber with a vinyl content of 20%. Take 40g of methyl vinyl silicone rubber, 16g of white carbon black, 2g of hydroxy silicone oil, 0.04g of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) he...

Embodiment 2

[0023] Get 70g octamethylcyclotetrasiloxane (D 4 ), 30g tetramethyltetravinylcyclotetrasiloxane (V 4 ), dehydrated at 40°C for 2h under vacuum conditions, then passed nitrogen to normal pressure, added 0.6g tetramethylammonium hydroxide silicon alkoxide (alkali gel) and 0.1g tetramethylhexasiloxane, and heated to 120°C, reacted for 2h under normal pressure. After the reaction, the temperature was raised to 170°C, and the small molecules in the product were removed under vacuum for 3 hours, and then cooled to room temperature to obtain a methyl vinyl silicone rubber with a vinyl content of 30%. Take 20g of methyl vinyl silicone rubber, 8g of white carbon black, 1g of hydroxy silicone oil, 0.02g of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane and knead, and take 10g of mixed rubber Vulcanize at 160°C for 20min. Cut the vulcanized rubber into rubber sheets of 1cm*1cm, and wash them ultrasonically with ethanol for 10min. Add 5g of mercaptopropionic acid, 0.05g of benzoin d...

Embodiment 3

[0025] Get 50g octamethylcyclotetrasiloxane (D 4 ), 50g tetramethyltetravinylcyclotetrasiloxane (V 4 ), dehydrated at 45°C for 2h under vacuum conditions, then passed nitrogen to normal pressure, added 0.6g tetramethylammonium hydroxide silicon alkoxide (alkali gel) and 0.1g tetramethylhexasiloxane, and heated to 130°C, react under normal pressure for 3h. After the reaction, the temperature was raised to 160°C, and the small molecules in the product were removed under vacuum for 3 hours, and then cooled to room temperature to obtain a methyl vinyl silicone rubber with a vinyl content of 50%. Take 20g of methyl vinyl silicone rubber, 8g of white carbon black, 1g of hydroxy silicone oil, 0.02g of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane and knead, and take 10g of mixed rubber Vulcanize at 160°C for 20min. Cut the vulcanized rubber into rubber sheets of 1cm*1cm, and wash them ultrasonically with ethanol for 10min. Add 5g of mercaptopropionic acid, 0.05g of benzoin dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com