Method using vacuum negative-pressure slip casting technology to prepare ITO target material

A technology of grouting molding and vacuum negative pressure, which is applied in the field of materials, can solve problems such as long molding time, insufficient strength, and difficulties in large-sized blanks, and achieve the goals of reducing time and cost, reducing internal stress, and improving product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

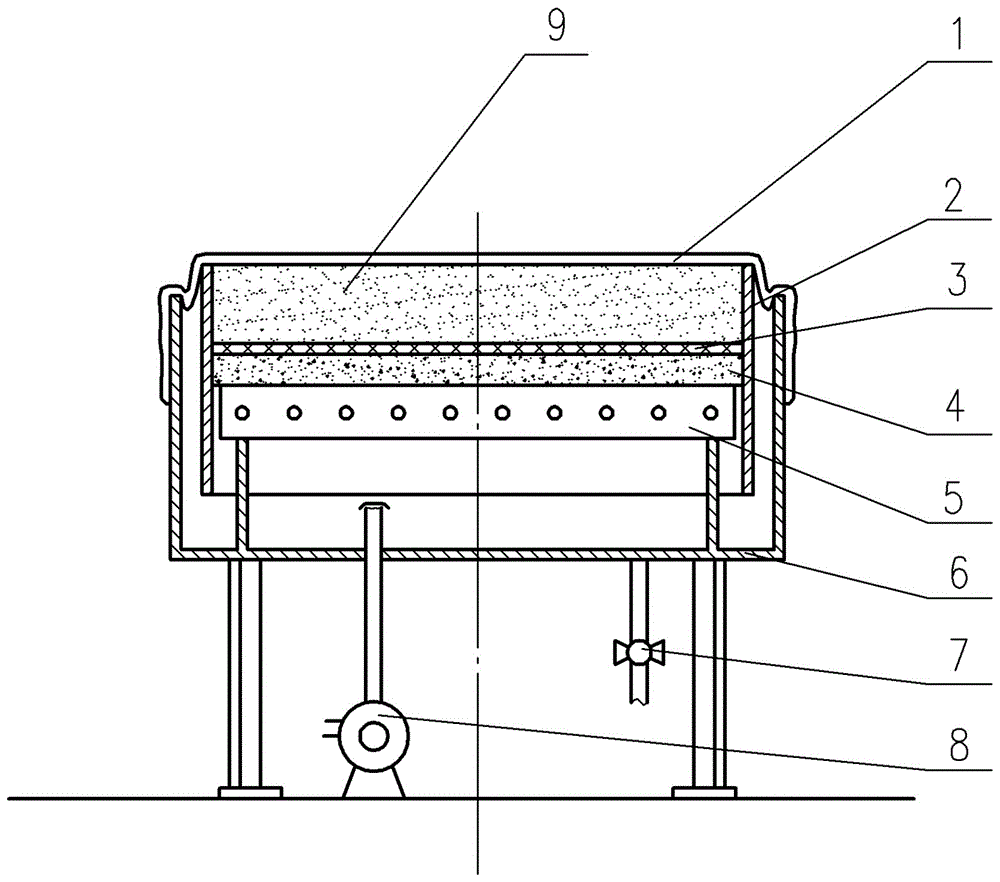

[0049] combined with figure 1 , First prepare the vacuum negative pressure grouting equipment, the size of the movable mold frame 2 is 300X600Xh mm, and the cavity height h is adjusted according to the needs.

[0050] Take 8000 g of indium oxide powder with a purity of more than 99.99% and an average particle size of 40 nm, 820 g of tin oxide powder, and 2000 g of sol with an indium oxide content of 10% and a particle size of 10 nm. After mixing them together, add them to the grinder and grind for 12 hours. The ground slurry 9 is subjected to vacuum degassing treatment, and then injected into the mold cavity, so that the slurry 9 completely fills the mold cavity and smoothes the surface, and is covered with a flexible high-temperature-resistant vacuum sealing film 1 .

[0051] Vacuum and dehydrate for 30 minutes, remove the water in the vacuum chamber 6, continue to vacuum and start heating, control the heating rate to be 10 degrees per hour, and keep the temperature for 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com