Structure and method for assisting traction skyline to cross river by cable crane traveling trolley

A walking trolley and auxiliary traction technology, which is applied to cable cranes, clockwork mechanisms, cranes, etc., can solve the problems of difficult demolition process, low safety factor of crossing the river, and threats to building safety, so as to save energy consumption and manpower , Improve the safety factor of crossing the river, and the effect of high safety factor of crossing the river

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

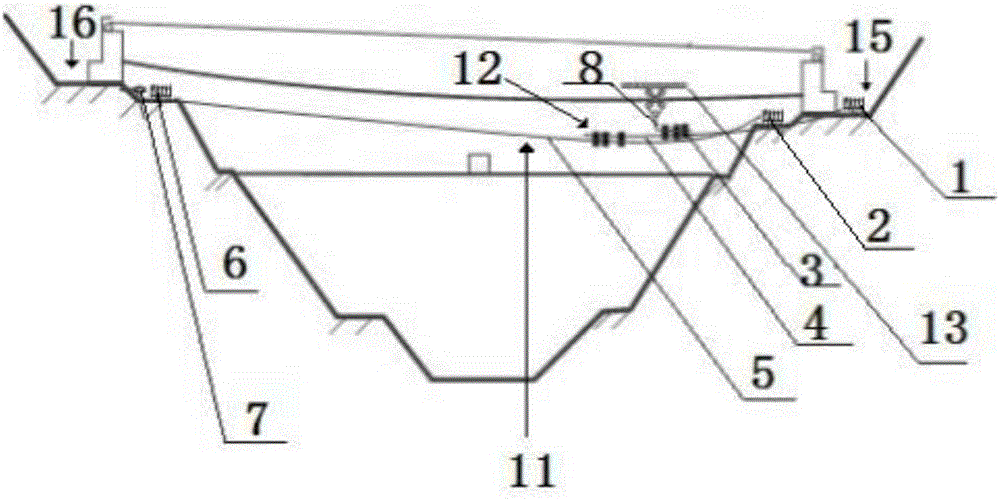

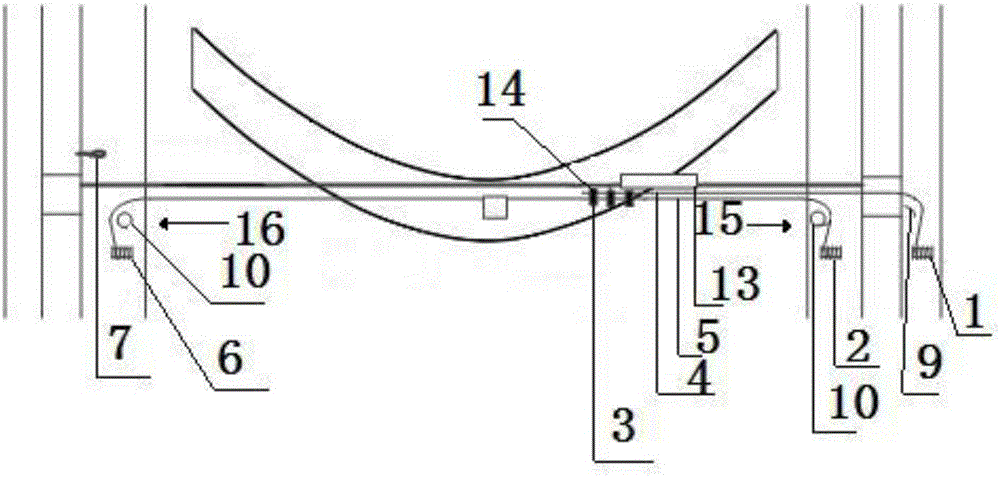

[0032] Referring to the accompanying drawings, it can be seen that the structure of the cable machine walking trolley assists in pulling the load-bearing cable across the river, including a traction system 11 and a connecting system 12, and is characterized in that: it also includes a cable machine walking trolley 13 and a lifting traction rope 8; the traction system 11 includes a cable Machine walking trolley 13, reciprocating rope 5, bearing cable hoist 1, release side reciprocating rope hoist 2, non-release side reciprocating rope hoist 6, curved rail 9, guide wheel 10; the connection system 12 includes rope clamp 3, filling steel wire 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com