Glass sucking disc sliding device

A sliding device and glass technology, which is applied in the field of mechanical processing, can solve the problems of waste of manpower and material resources and a lot of time, the inability to adjust the direction of the glass sheet, and heavy weight, etc., and achieve the effect of convenient operation, uniform force on the glass, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

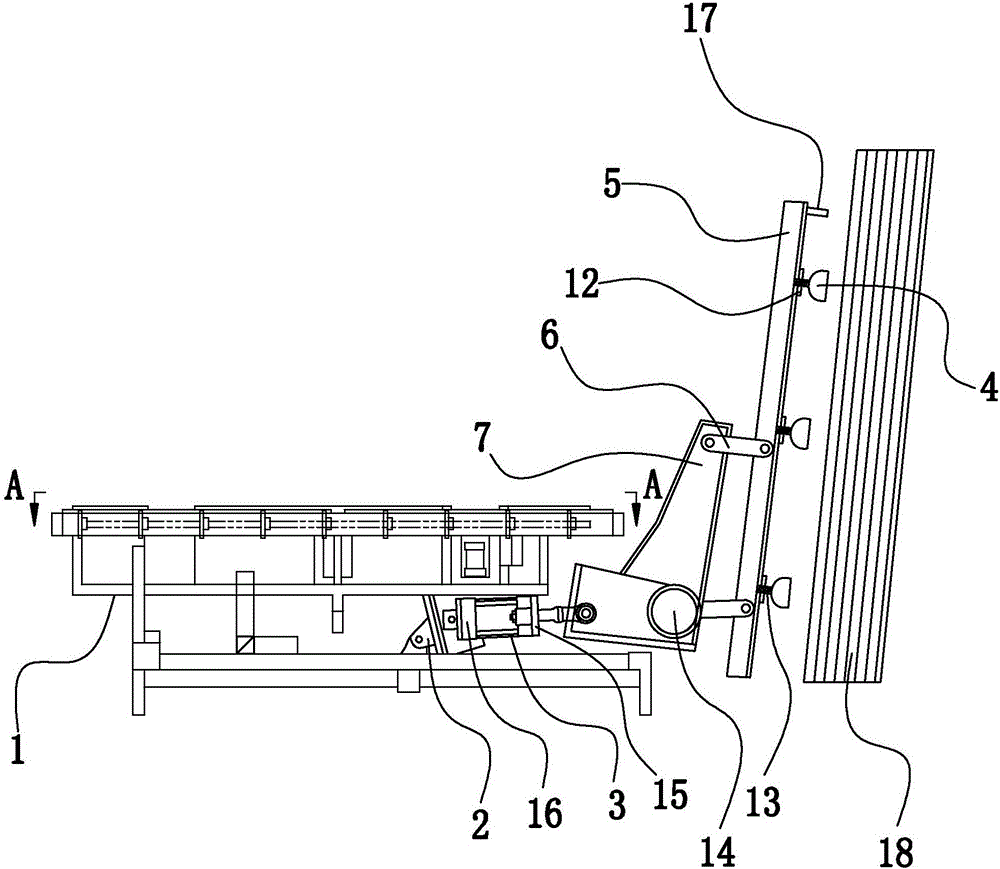

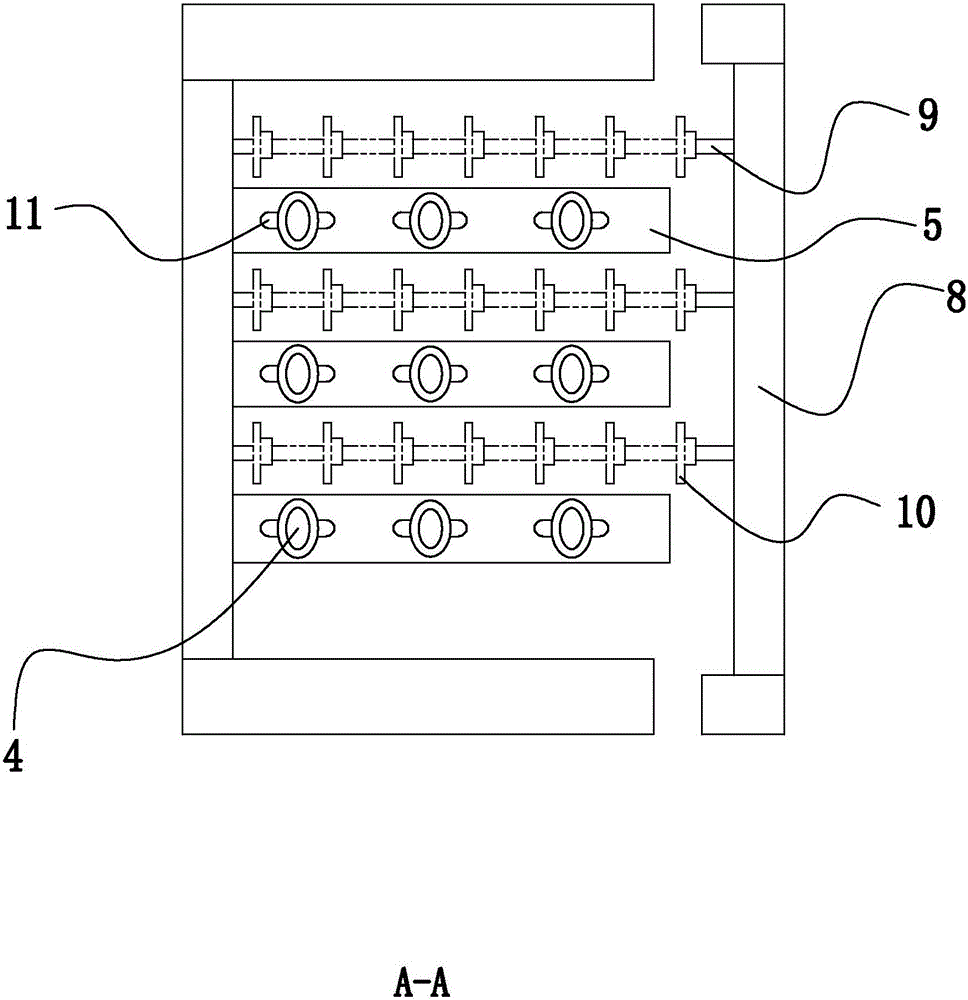

[0021] Example: such as Figure 1-2 As shown, a glass suction cup sliding device includes a frame 1, a glass turning device and a glass bearing device arranged on the frame 1; a turning support seat 2 and a driving cylinder 3 are installed on the frame 1; Support base 2 and driving cylinder 3 are installed on the frame 1, and glass turning device is driven by driving cylinder 3, realizes turning over; Described glass turning device comprises carrying bar 5, the sucker 4 that is arranged on carrying bar 5; Carrying bar 5 A rocking bar 7 is arranged at the lower end, and the carrying rod 5 and the rocking bar 7 are rotationally connected through a parallel arm 6 .

[0022] There are at least two bearing rods 5 on the glass turning device, and each bearing rod 5 equipped with a suction cup 4 is provided with an independent drive cylinder 3; to ensure the consistency of the motion connection between the bearing rod 5 and the drive cylinder 3; the suction cup 4 It is detachably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com