Colored metal 3D printing wire and preparing method thereof

A 3D printing and colored metal technology, applied in the field of 3D printing, can solve problems such as single color, mechanical strength that cannot meet the requirements of mechanical strength, and color metal printing wires that have not yet been provided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

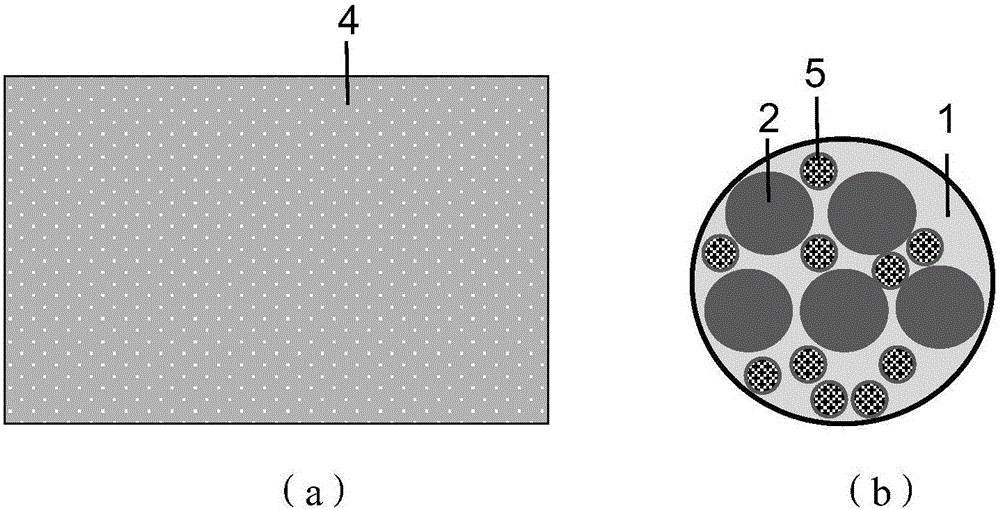

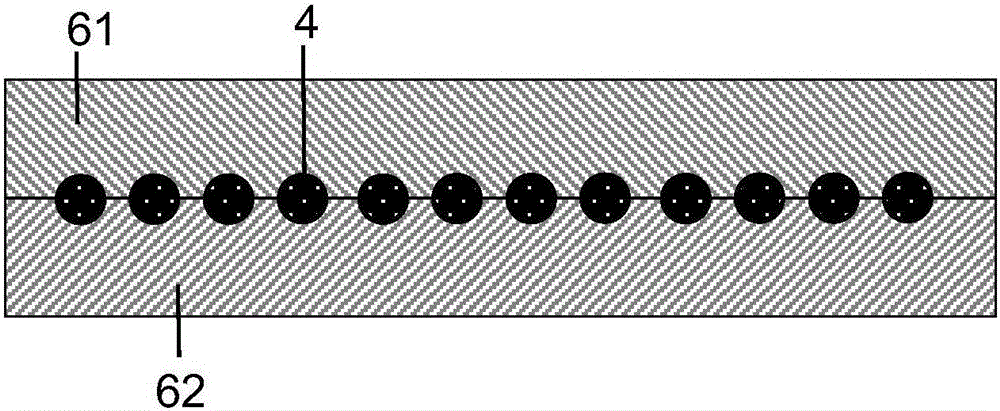

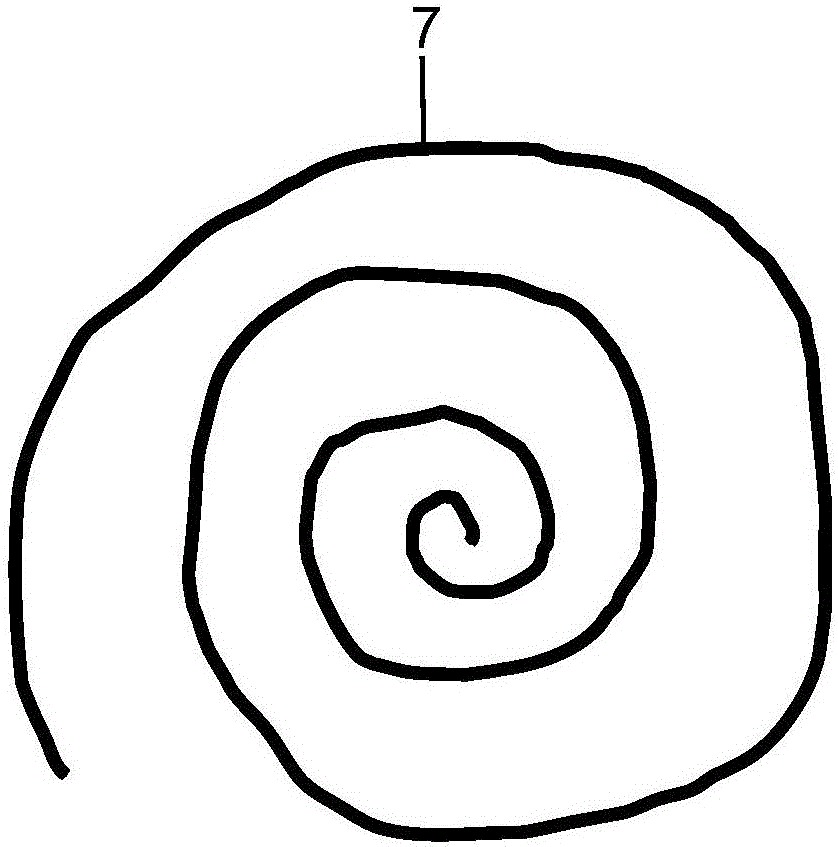

[0056] like Figure 1-2 As shown, a color metal 3D printing wire, its raw materials include low melting point metal 1, pigment 2 and nano conductive particles 5; the low melting point metal is indium bismuth alloy In66.3Bi33.7; the pigment is cinnabar; the The nano-conductive particles are nano-titanium with a particle diameter of 600 nm;

[0057] The mass ratio of the low melting point metal, the pigment and the nano conductive particles is 40:4:1.

[0058] This embodiment also provides a method for preparing the colored metal 3D printing wire, including the following steps:

[0059] S1: Weigh the low melting point indium bismuth alloy In according to the proportion 66.3 Bi 33.7 , pigment cinnabar and nano-conductive titanium particles;

[0060] Among them, indium bismuth alloy In 66.3 Bi 33.7 The preparation method includes mixing metal indium and bismuth in a 300 ℃ high temperature vacuum furnace environment according to the mass ratio of 66.3:33.7, and cooling;

[0...

Embodiment 2-11

[0067] The raw materials of the colored metal 3D printing wire include low-melting-point metals, pigments and nano-conductive particles. The only difference from Example 1 is that the types of pigments are different (the diameter of the pigment particles is the same). The preparation method of the colored metal wire is the same as that in Example 1. The strengths of the colored metal 3D printing wires in Examples 2-11 all meet the requirements of 3D printing wires.

[0068]

Embodiment 12-20

[0070] The raw materials of the colored metal 3D printing wire include low melting point metal 1, pigment 2 and conductive particles 5 with a diameter of 300 nm. The only difference from Example 1 is the type of nano conductive particles (see the table below). The preparation method of the colored metal 3D printing wire is the same as that in Example 1. The strengths of the colored metal 3D printing wires in Examples 12-20 all meet the requirements of the 3D printing wires.

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com