Wire-break braking device and method for aluminum-magnesium alloy wire drawing machine

A brake device and aluminum-magnesium alloy technology, which is applied in the field of aluminum-magnesium wire drawing, can solve the problems of messy wires, affecting production output, wasting energy, etc., and achieve the effects of improving production efficiency, shortening wiring time, and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

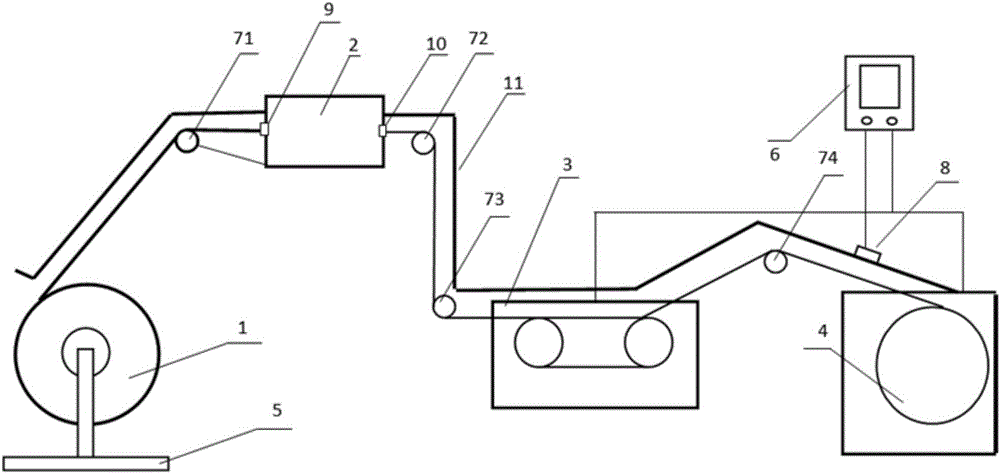

[0017] The brake device for wire breakage of aluminum-magnesium alloy wire drawing machine includes: pay-off device (1), wire drawing die (2), wire draw device (3), wire take-up device (4), base (5), PLC controller (6), rollers (71), roller (72), roller (73), roller (74); the base (5) is fixedly connected with the ground, and the pay-off device (1) is connected with the base (5) through the bearing; There are wire inlets (9) and wire outlets (10) at the end respectively, and rollers (71) and rollers (72) are respectively provided in the wire inlet direction and the wire outlet direction, and the wire inlet and wire outlet directions are rollers (71) respectively. and the upper end point of the roller (72) in the tangential direction, the roller (71) is arranged above the wire-releasing device (1); One end of the direction of the line is provided with a roller (73), and the other end is provided with a roller (74); the take-up device is arranged on the other end of the roller (...

Embodiment 2

[0020] The brake device for wire breakage of aluminum-magnesium alloy wire drawing machine includes: pay-off device (1), wire drawing die (2), wire draw device (3), wire take-up device (4), base (5), PLC controller (6), rollers (71), roller (72), roller (73), roller (74); the base (5) is fixedly connected with the ground, and the pay-off device (1) is connected with the base (5) through the bearing; There are wire inlets (9) and wire outlets (10) at the end respectively, and rollers (71) and rollers (72) are respectively provided in the wire inlet direction and the wire outlet direction, and the wire inlet and wire outlet directions are rollers (71) respectively. and the upper end point of the roller (72) in the tangential direction, the roller (71) is arranged above the wire-releasing device (1); One end of the direction of the line is provided with a roller (73), and the other end is provided with a roller (74); the take-up device is arranged on the other end of the roller (...

Embodiment 3

[0023] The brake device for wire breakage of aluminum-magnesium alloy wire drawing machine includes: pay-off device (1), wire drawing die (2), wire draw device (3), wire take-up device (4), base (5), PLC controller (6), rollers (71), roller (72), roller (73), roller (74); the base (5) is fixedly connected with the ground, and the pay-off device (1) is connected with the base (5) through the bearing; There are wire inlets (9) and wire outlets (10) at the end respectively, and rollers (71) and rollers (72) are respectively provided in the wire inlet direction and the wire outlet direction, and the wire inlet and wire outlet directions are rollers (71) respectively. and the upper end point of the roller (72) in the tangential direction, the roller (71) is arranged above the wire-releasing device (1); One end of the direction of the line is provided with a roller (73), and the other end is provided with a roller (74); the take-up device is arranged on the other end of the roller (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com