Large-caliber organic matter treatment equipment

A processing equipment, large-diameter technology, applied in mechanical equipment, grain processing, large containers, etc., can solve the problems of inability to achieve blasting effect, difficult to increase the effective cross-sectional area, and difficult to increase the pressure relief speed of the pressure relief device. , to achieve the effect of compact structure, increasing force and reducing thrust demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

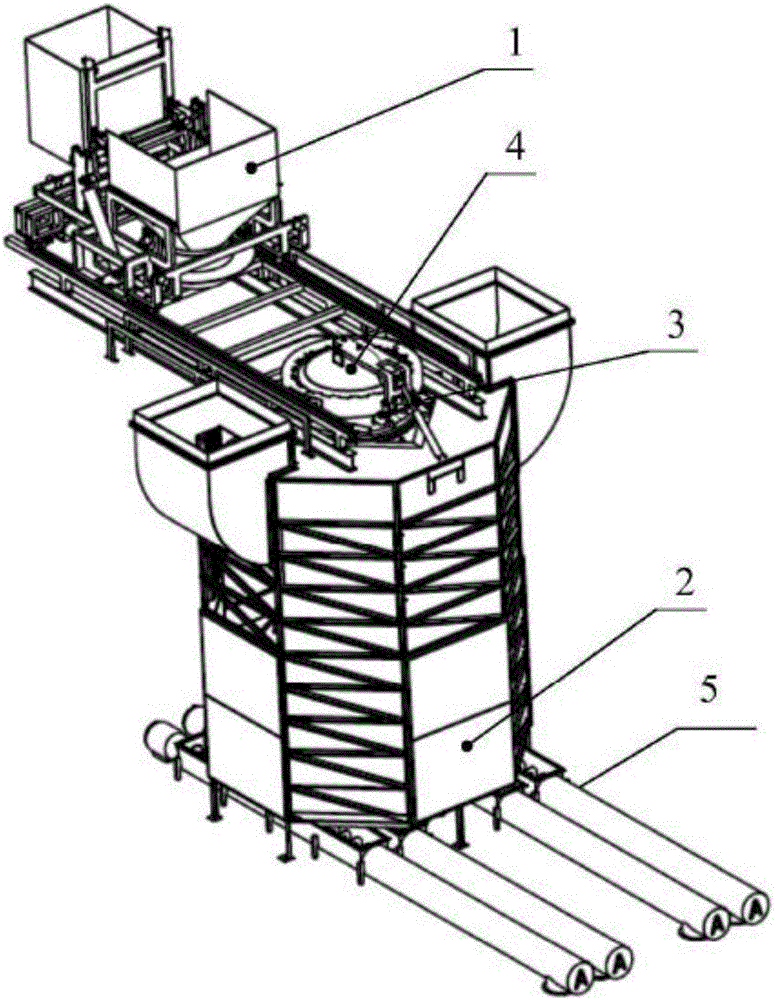

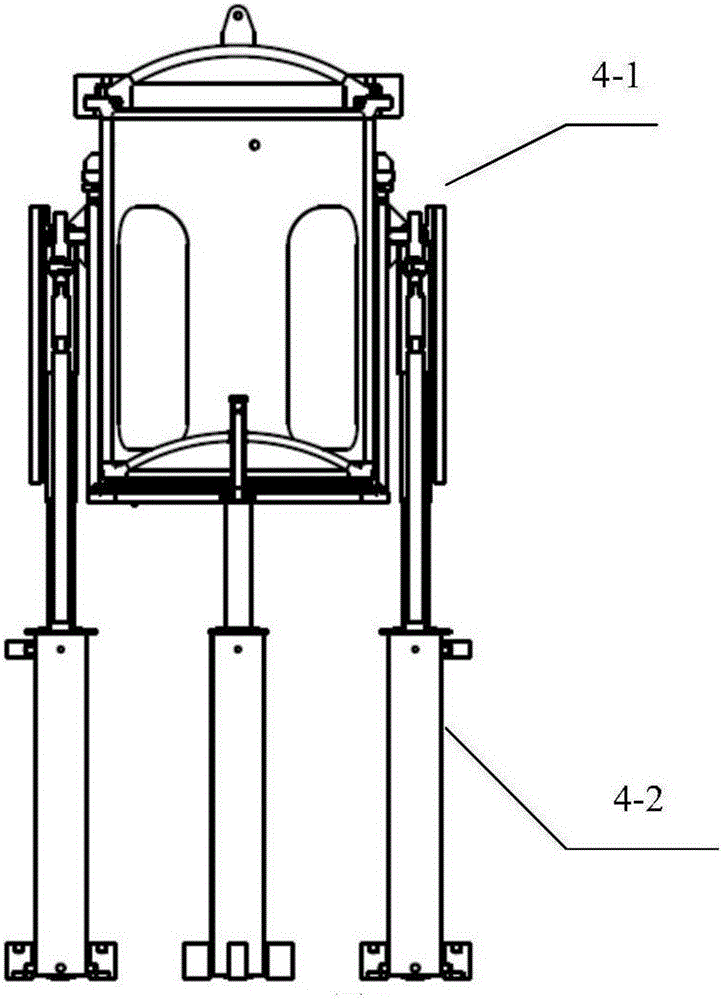

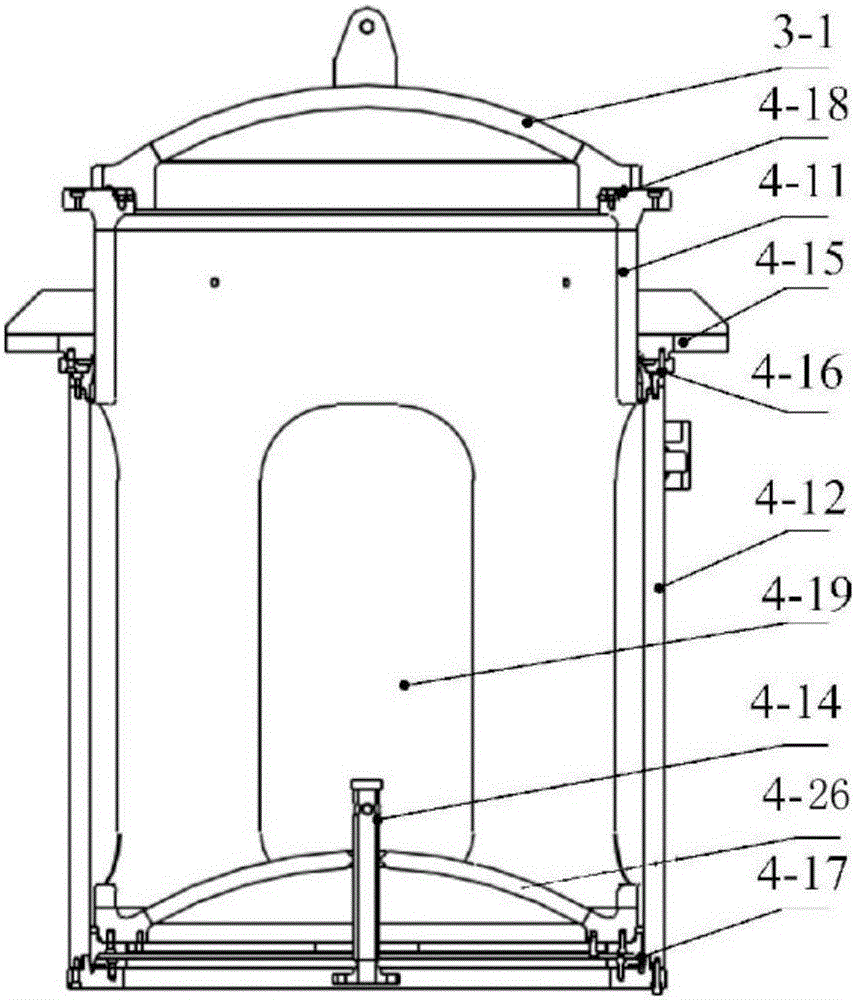

[0063] Such as figure 1 Shown is a schematic structural diagram of the large-diameter organic matter processing equipment. It can be seen from the figure that the large-diameter organic matter processing equipment specifically includes a feeding device 1, a separator 2, a cover opening mechanism 3, a pressurization and pressure relief device 4, and a discharge device 5. The pressure relief device 4 is installed inside the separator 2, the cap opening mechanism 3 and the feeding device 1 are installed on the upper part of the pressure relief device 4, that is, the top of the separator 2, and the discharge device 5 is located below the separator 2 , wherein the feeding device 1 injects the material into the inside of the pressure relief device 4 through the cap opening device 3, the pressure relief device 4 heats and pressurizes the material, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com