Steel ball automatic sorting equipment

An automatic sorting and steel ball technology, applied in classification, solid separation, coating, etc., can solve the problems affecting the production cycle of enterprises, low production efficiency, incomplete screening, etc., to improve work efficiency, improve production efficiency, and sort Pick the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

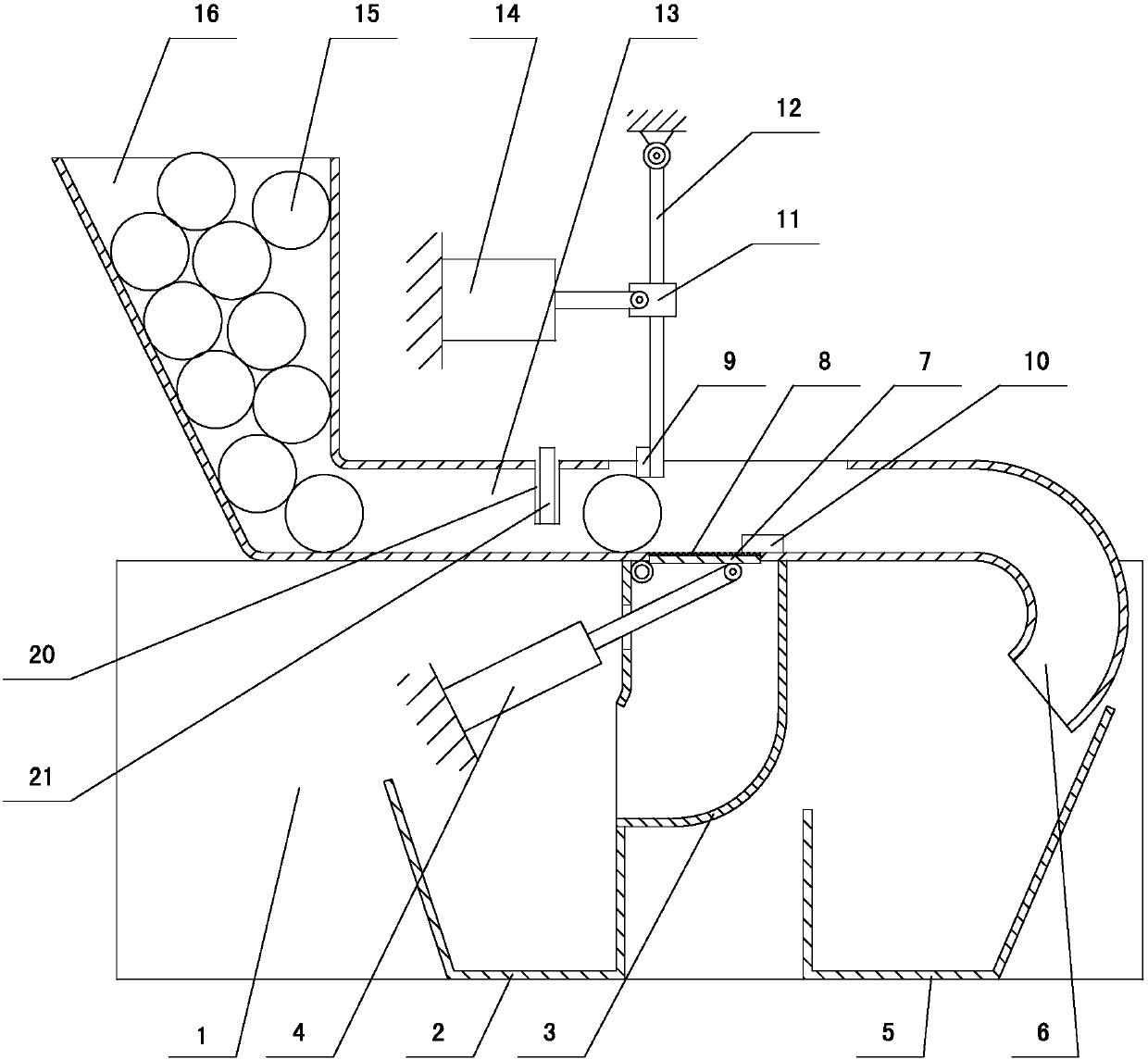

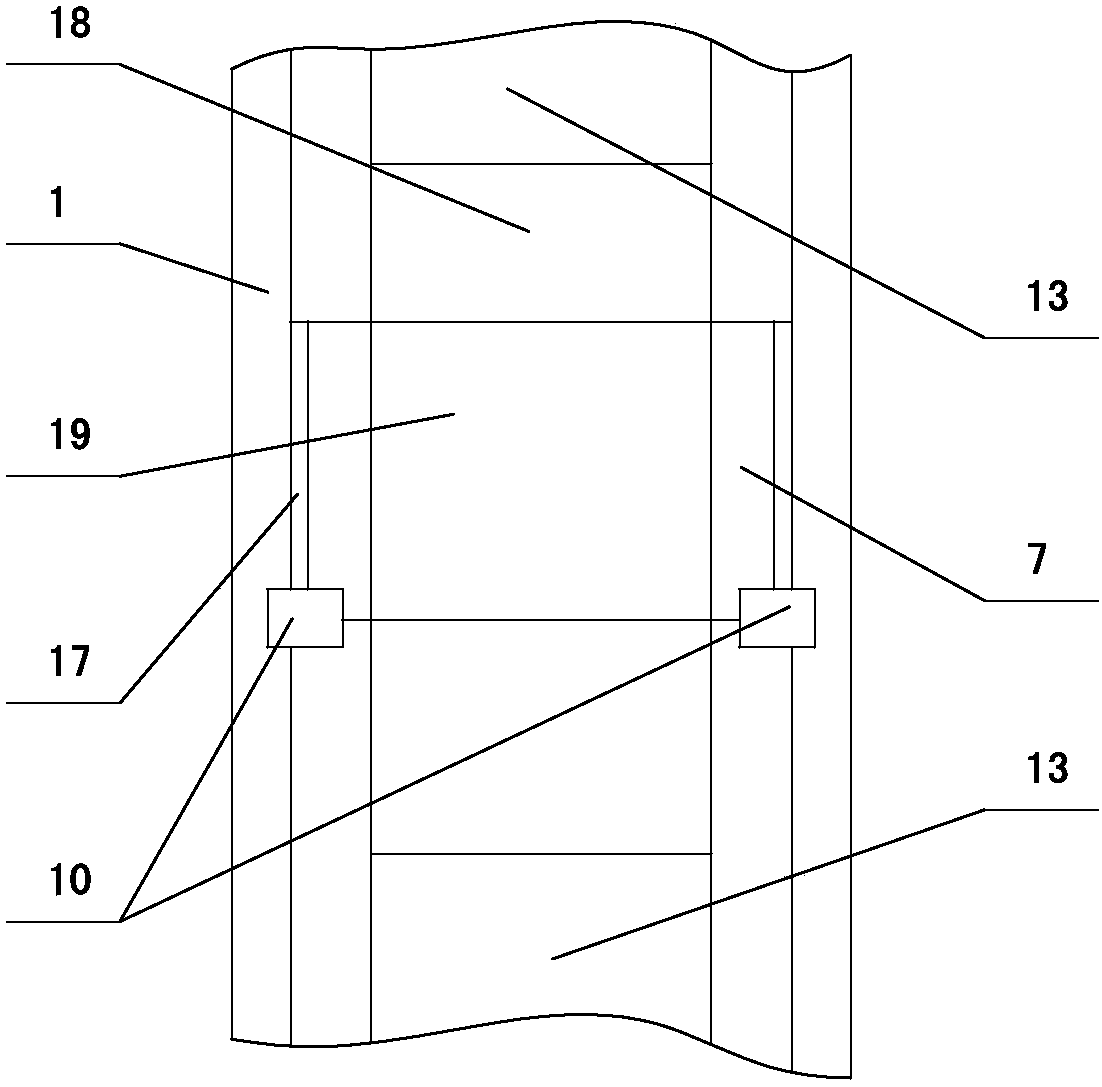

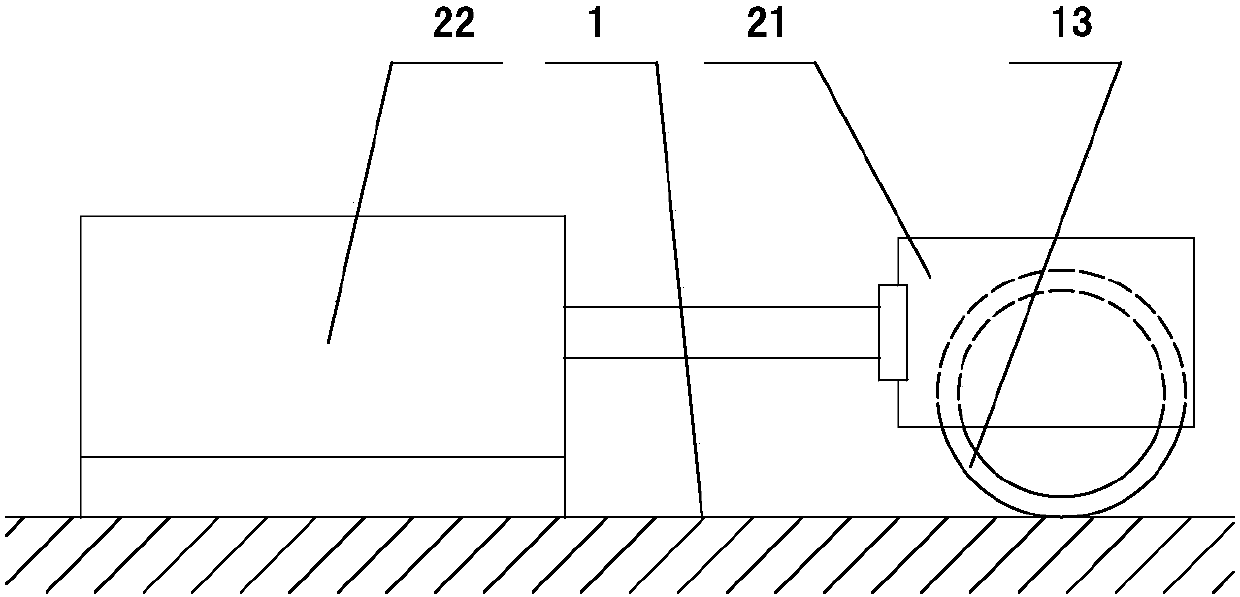

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Depend on Figure 1 ~ Figure 3 The structure schematic diagram of the steel ball automatic sorting equipment of the present invention shown shows that it includes a frame 1, a barrel 16, a feeding pipe 13, a ball blocking device, a sorting device, and a first drop for sorting large-sized balls. feeding device and a second feeding device for sorting small sized spheres. The feed tube 13 and the barrel 16 filled with steel balls 15 are connected to the frame 1 , and the outlet of the barrel 16 communicates with the inlet end of the feed tube 13 . The ball blocking device is located between the sorting device and the barrel, and the fixed end of the ball blocking device is installed on the frame, and the movable end is inserted into or extracted from the feeding pipe 13 . The sorting device is installed on the frame 1 and locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com