Micron molybdenum disulfide hydrogen evolution electro-catalytic material, preparation method and application of micron molybdenum disulfide hydrogen evolution electro-catalytic material

An electrocatalytic material, molybdenum disulfide technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of difficult to obtain micron or nanoscale materials, high hydrogen evolution overpotential, difficult to efficiently controllable combination, etc., to achieve good industrialization Basic production, good repeatability, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

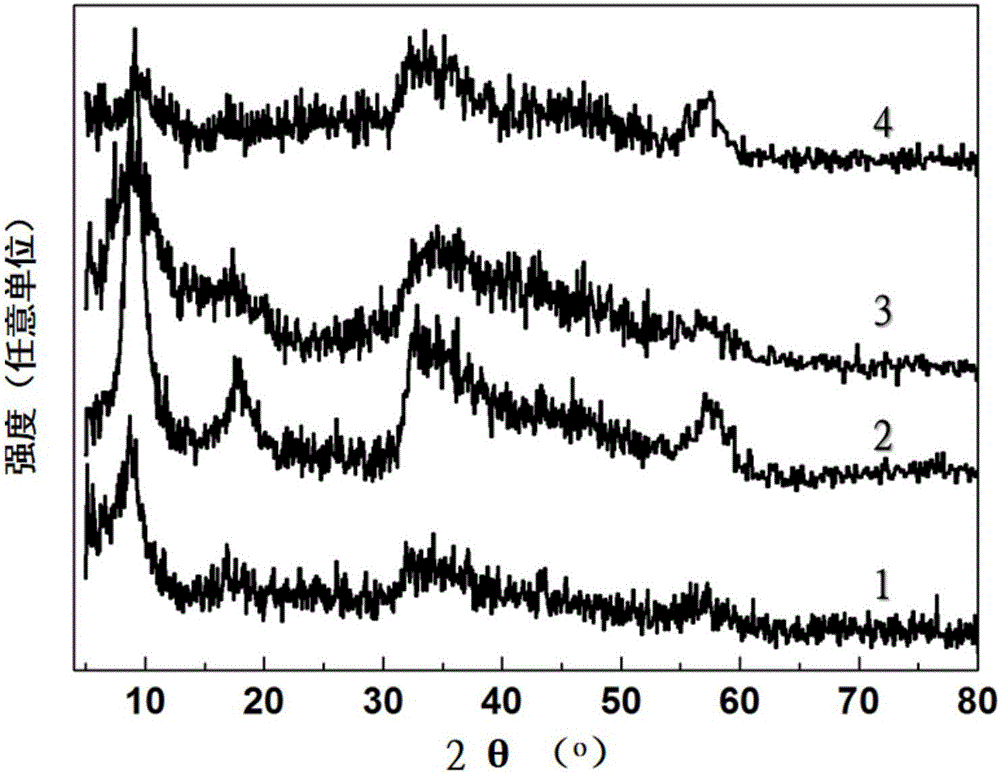

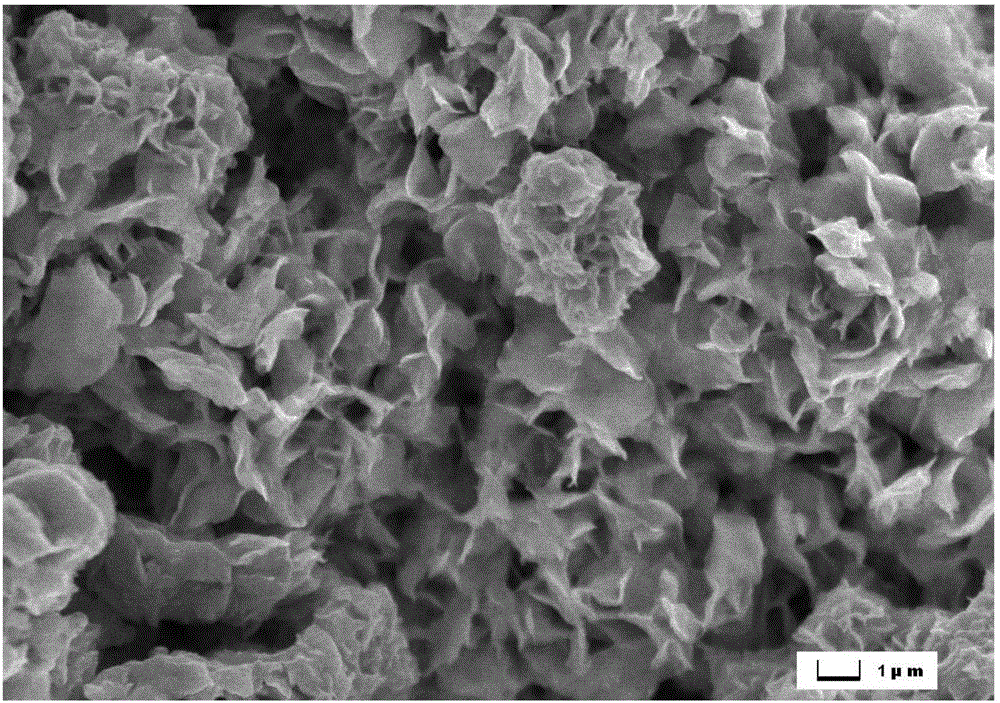

[0031] Dissolve 0.31g (0.00025mol) ammonium heptamolybdate tetrahydrate into 10.0mL N,N'-dimethylformamide to prepare a 0.025mol / L solution, then add 0.57g (0.0075mol) thiourea, use Stir with a magnetic stirrer (500r / min) for 30min, transfer the stirred solution to a hydrothermal reaction kettle with a volume of 30mL, conduct a hydrothermal reaction at 220°C for 24h, then cool naturally, centrifuge, and deionize in turn After washing with water and ethanol and drying, 0.42 g of molybdenum disulfide microsheet hydrogen evolution electrocatalyst was obtained. From figure 2 It can be seen that the product is a microsheet structure.

[0032] The test was performed on an electrochemical workstation (Gamry Reference 600 Instruments, USA) using a three-electrode system. Disperse 5.0 mg of molybdenum disulfide prepared in this example as a catalyst and 20.0 μL Nafion (5wt%) solution in an ethanol-water mixed solution (volume ratio of ethanol: water is 1:1), and ultrasonically treat...

Embodiment 2

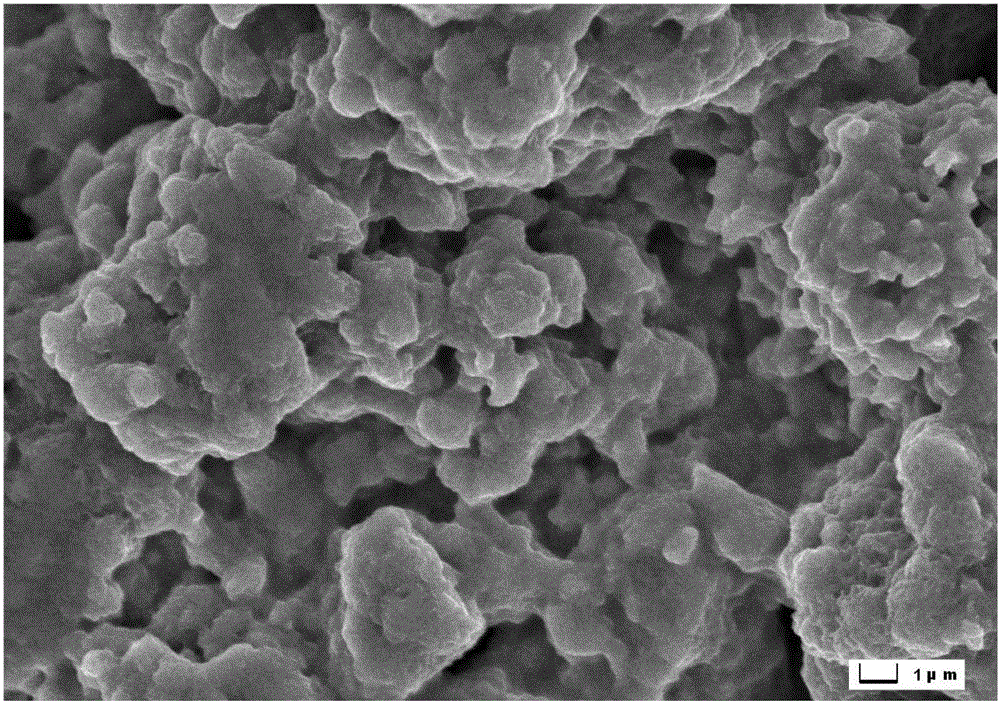

[0034] Dissolve 0.31g (0.00025mol) ammonium heptamolybdate tetrahydrate into 10mL N,N'-dimethylformamide / deionized water (volume ratio = 1:1) mixed solution to prepare a 0.025mol / L solution , then add 0.57g (0.0075mol) thiourea, stir with a magnetic stirrer for 30min (stirring speed 1000r / min), transfer the stirred solution to a hydrothermal reaction kettle with a volume of 30mL, and carry out hydrothermal reaction at 220°C. Thermal reaction for 24h, then natural cooling, drying after centrifugation, deionized water and ethanol washing to obtain 0.37g molybdenum disulfide micro-sheets, from image 3 As can be seen, the product is a microsheet structure, but agglomeration is beginning to occur.

[0035] The test was performed on an electrochemical workstation (Gamry Reference 600 Instruments, USA) using a three-electrode system. Disperse 5.0 mg of molybdenum disulfide prepared in this example as a catalyst and 20.0 μL Nafion (5wt%) solution in an ethanol-water mixed solution (...

Embodiment 3

[0037] Dissolve 0.62g (0.0005mol) ammonium heptamolybdate tetrahydrate into 10mL N,N'-dimethylformamide / deionized water (volume ratio = 1:1) mixed solution to prepare a 0.05mol / L solution , add 1.14g (0.015mol) thiourea again, utilize magnetic stirrer to stir 30min (stirring speed 1000r / min), the solution after stirring is transferred to the hydrothermal reaction kettle that volume is 30mL, carry out water under the condition of 220 ℃ Thermal reaction for 24h, then natural cooling, drying after centrifugation, deionized water and ethanol washing to obtain 0.68g molybdenum disulfide micro-sheets, from Figure 4 It can be seen that the product agglomeration phenomenon is serious.

[0038] The test was performed on an electrochemical workstation (Gamry Reference 600 Instruments, USA) using a three-electrode system. Disperse 5.0 mg of molybdenum disulfide prepared in this example as a catalyst and 20.0 μL of Nafion (5wt%) solution in an ethanol-water mixed solution (volume ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com