Nanometer Cu0/Fe3O4 compound, method for preparing same and application of nanometer Cu0/Fe3O4 compound to treating organic wastewater by means of catalytically activating molecular oxygen

A technology of organic wastewater and catalytic activation, applied in the interdisciplinary field, can solve the problem of low catalyst activity and achieve the effects of wide application value, high catalytic activity and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

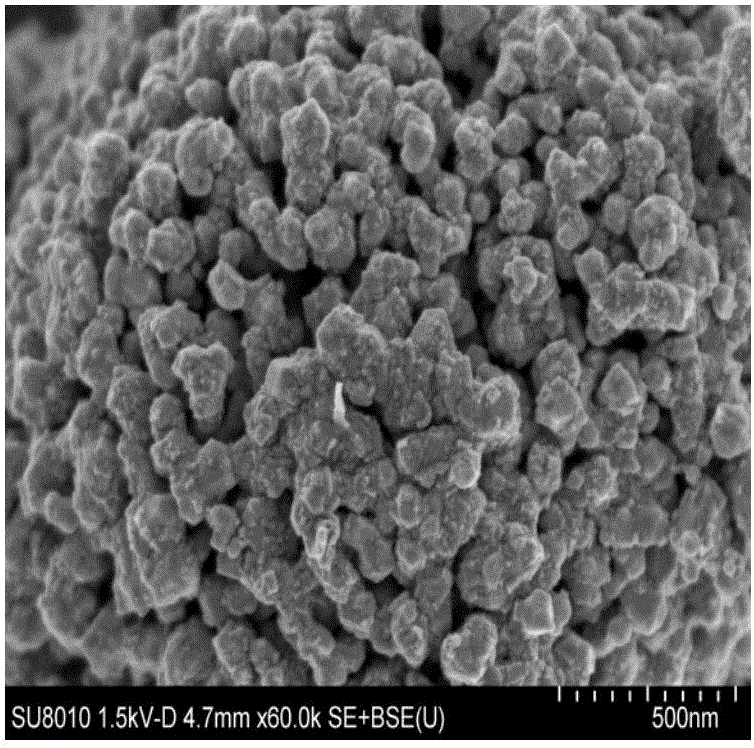

[0031] According to Cu(NO 3 ) 2 ·3H 2 O and Fe(NO 3 ) 3 9H 2O molar ratio is the ratio of 1:3, weigh 5mmol Cu(NO 3 ) 2 ·3H 2 O and 15mmol Fe(NO 3 ) 3 9H 2 O, dissolved in 55mL of ethylene glycol, stirred at 25°C for 120min; transferred the obtained mixture to a polytetrafluoroethylene reactor with a capacity of 100ml, and reacted at 180°C for 24h to obtain a black precipitate; Separation by centrifugation, washing the obtained black precipitate with deionized water until the cleaning solution is neutral, that is, nano-Cu 0 / Fe 3 o 4 Composite (Cu 0 / Fe molar ratio content is 1:3). It was confirmed by XRD and SEM that the prepared catalyst was indeed nano-Cu 0 / Fe 3 o 4 Compounds such as figure 1 As shown, the particle size is about 50-70nm, such as figure 2 shown.

Embodiment 2

[0033] 5 mg L in 50 mL -1 Add HNO to the rhodamine B aqueous solution 3 or NaOH to adjust the pH value to 7.0, and feed air so that the molecular oxygen concentration in water is 2.0mg / L, add the Cu prepared in 50mg embodiment 1 0 / Fe 3 o 4 Composite catalyst (Cu 0 / Fe molar ratio content is 1:3), mechanical stirring at room temperature. After 40min, the degradation rate of Rhodamine B was 99%, as image 3 As shown, the total organic carbon (TOC) dropped by 55%.

[0034] Under the same experimental conditions, the concentration in two cups of 50mL is 5mg L -1 Add 50mgCu to Rhodamine B wastewater 0 and 50mg Fe 3 o 4 Catalyst, after reacting for 40min, Cu 0 Catalyst has a degradation rate of 25% for Rhodamine B, Fe 3 o 4 Catalyst has a degradation rate of Rhodamine B of 33%, Cu 0 The catalyst corresponds to a 6% drop in total organic carbon (TOC), Fe 3 o 4 The catalyst corresponds to a 14% drop in total organic carbon (TOC).

Embodiment 3

[0036] According to Cu(NO 3 ) 2 ·3H 2 O and Fe(NO 3 ) 3 9H 2 O molar ratio is the ratio of 1:7, weighs 2.5mmol Cu (NO 3 ) 2 ·3H 2 O and 17.5mmol Fe(NO 3 ) 3 9H 2 O, dissolved in 55mL of ethylene glycol, stirred at 60°C for 30min; transferred the obtained mixture to a polytetrafluoroethylene reactor with a capacity of 100ml, and reacted at 150°C for 96h to obtain a black precipitate; Separation by centrifugation, washing the obtained black precipitate with deionized water until the cleaning solution is neutral, that is, nano-Cu 0 / Fe 3 o 4 Composite (Cu 0 / Fe molar ratio content is 1:7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com