Filling machine and method for filling pasty substances

A paste-like substance and filling machine technology, applied in the field of filling paste-like substance, can solve problems such as channel blockage, degassing and distribution accuracy deterioration, and achieve the goal of ensuring degassing, reducing cleaning efforts, and ensuring process reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

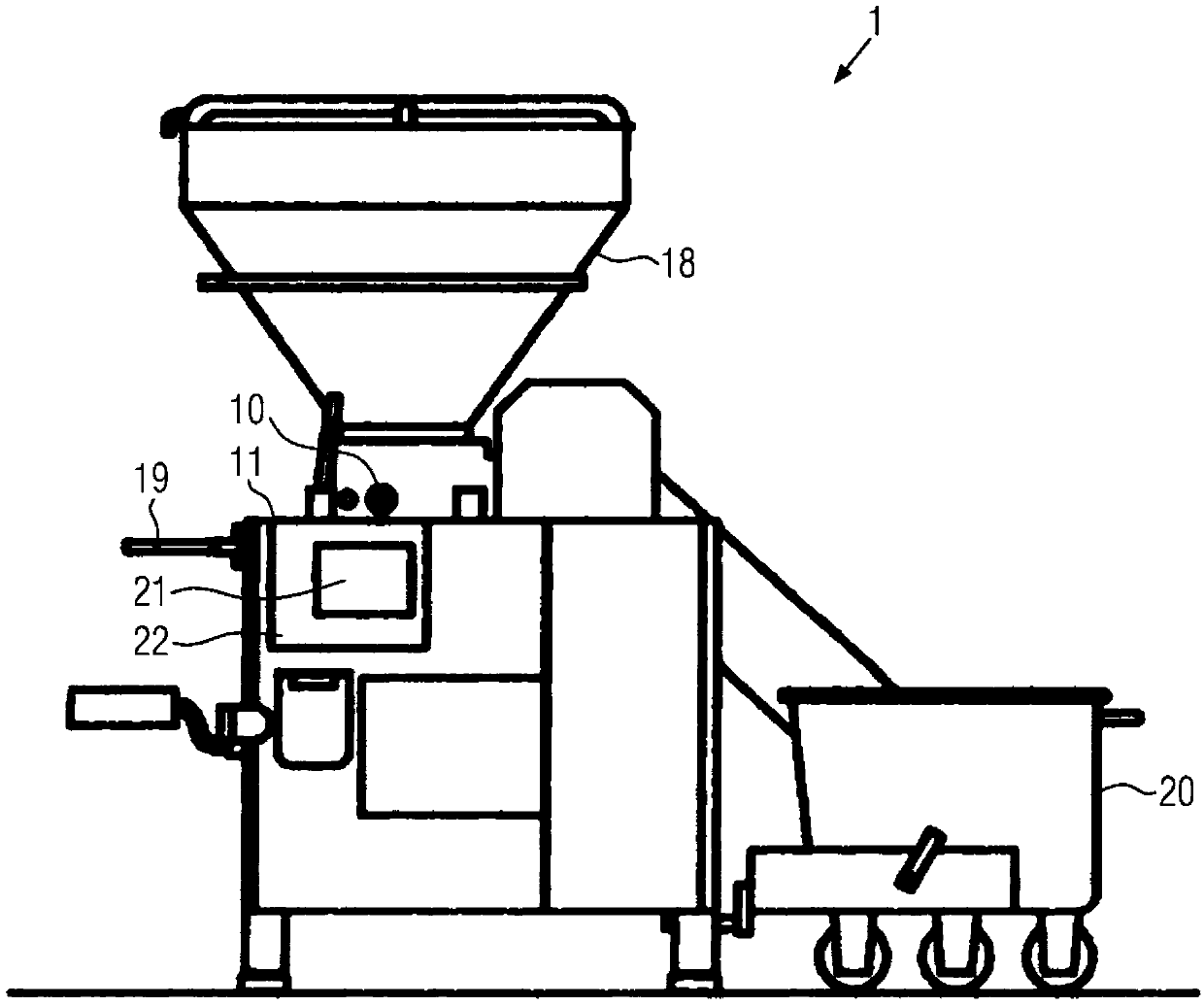

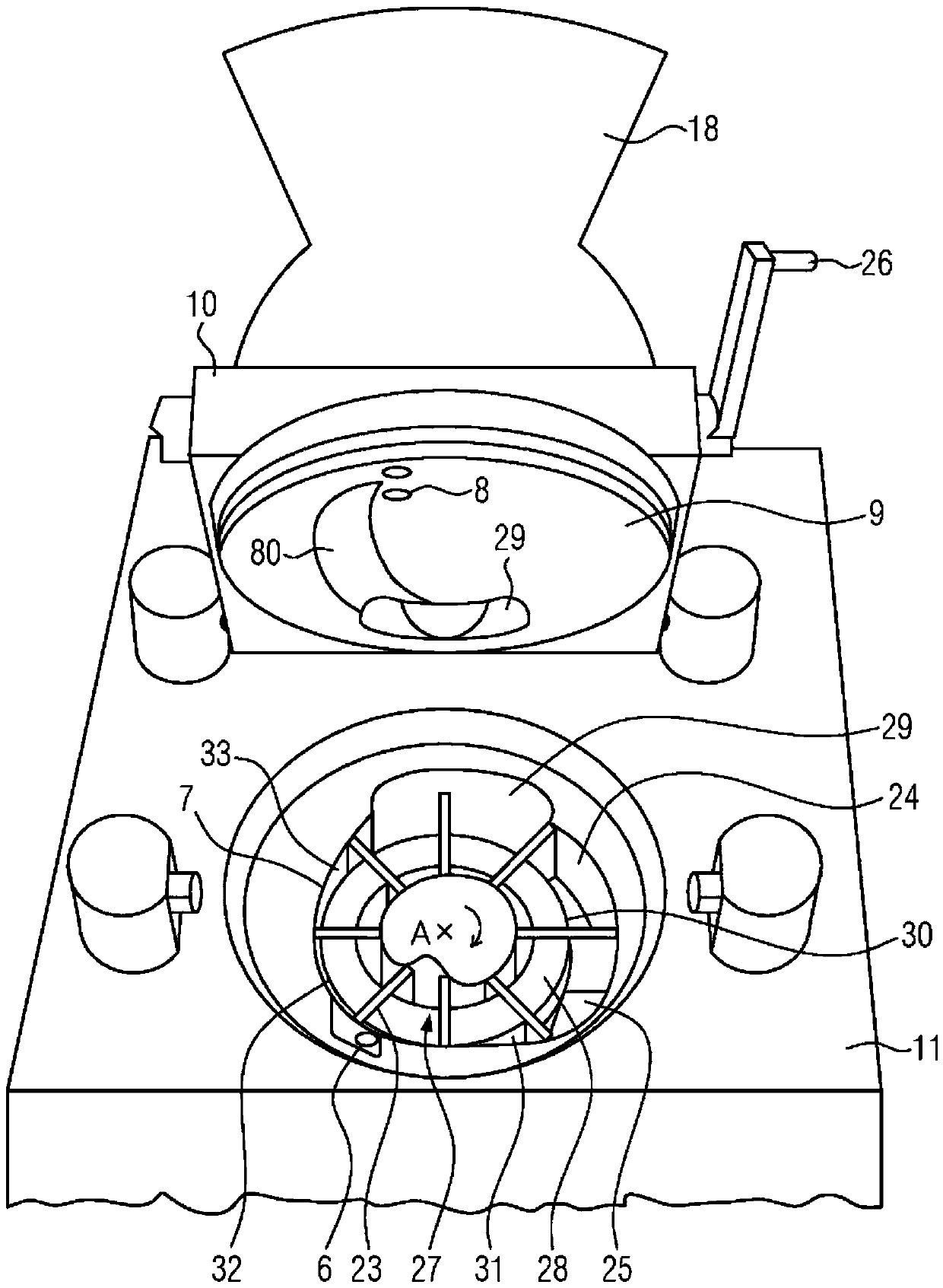

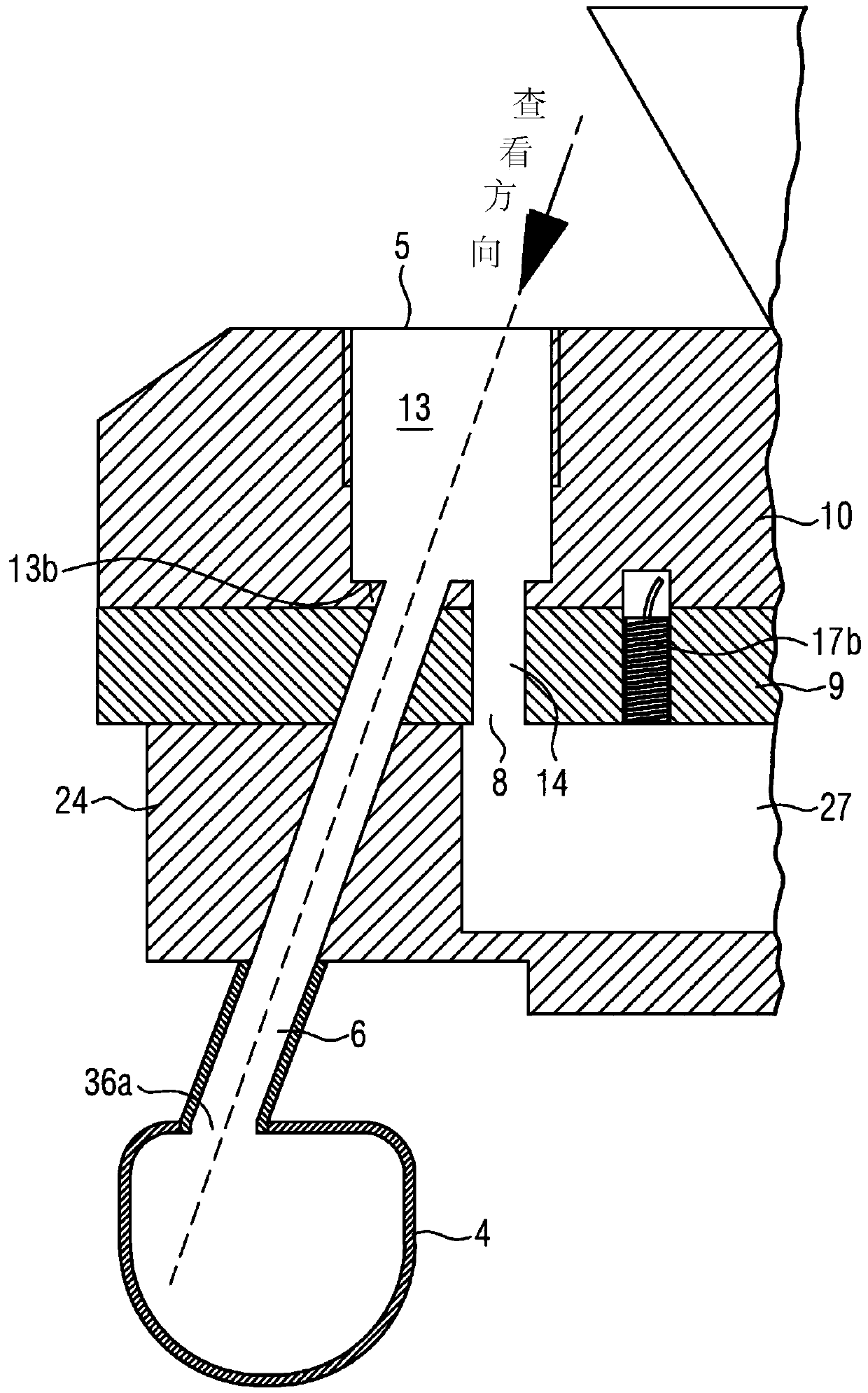

[0038] figure 1 Very schematically shows a side view of the filling machine according to the invention. The filling machine 1 includes a hopper 18 for receiving pulpy substances. This hopper 18, if still from figure 2 It is obvious that it is arranged on the pivot housing 10 so that the pivot housing can be pivoted for opening the vane unit pump, the pivot housing 10 including the cover 9 of the vane unit pump. The vane unit pump is arranged under the hopper. The filling machine 1 also includes a filling tube 19. The pulpy substance is pushed into the filling tube 19 by the vane unit pump and then squeezed into, for example, sausage casings in a known manner. The filling machine also includes a controller 22 and a display 21. In this embodiment, the filling machine also includes a lifting device with a sausage meat compartment 20, which can be used to raise the pulpy substance and pour it into the hopper 18. The filling machine includes a machine housing 11 in which the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com