Compound sliding block structure

A composite type and slider technology, applied in the field of die-casting molds, can solve problems such as inability to effectively eliminate air trapping in products, low yield rate, complex structure, etc., and achieve the effect of simple structure, low cost, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

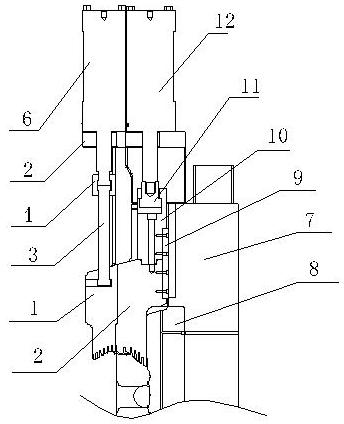

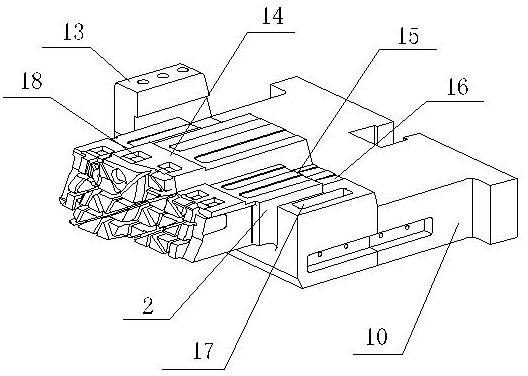

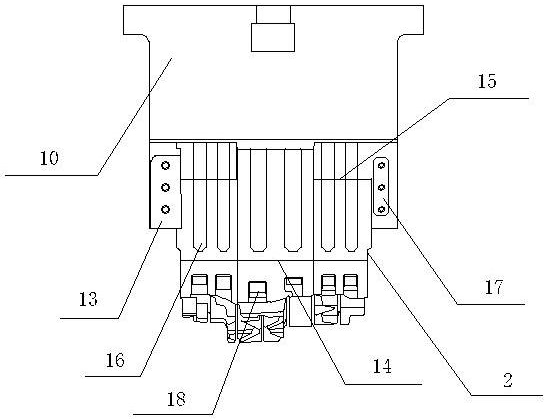

[0021] Example: such as figure 1 As shown, a composite slider structure includes an oil cylinder, a composite slider, a movable mold frame 7 and a movable mold core 8, the movable mold frame 7 and the movable mold core 8 form a movable mold, and the composite slider includes a driven slider 1 and a movable mold core 8. The lower basic slider 2 has six parallel process slag discharge grooves 16 on the upper end surface of the lower basic slider 2, which are used to remove the aluminum skin blown or squeezed in during the movement of the composite slider, and oil cooling Liquid, etc., to ensure smooth and safe mechanical movement, one end of the process slag discharge tank 16 points to the front end of the lower basic slider 2, and the other end points to the rear end of the lower basic slider 2, and at the same time, it is integrated on the upper end surface of the lower basic slider 2 A first progress hindering part 14 and a second progress hindering part 15 are made, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com