Reluctance rotor field modulation double-stator brushless doubly-fed motor

A doubly-fed motor and double-stator technology, applied to electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of complex structure of wound rotors, difficult design and processing, and large volume of motors, and achieve simple and reliable structure , easy transportation and on-site installation, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

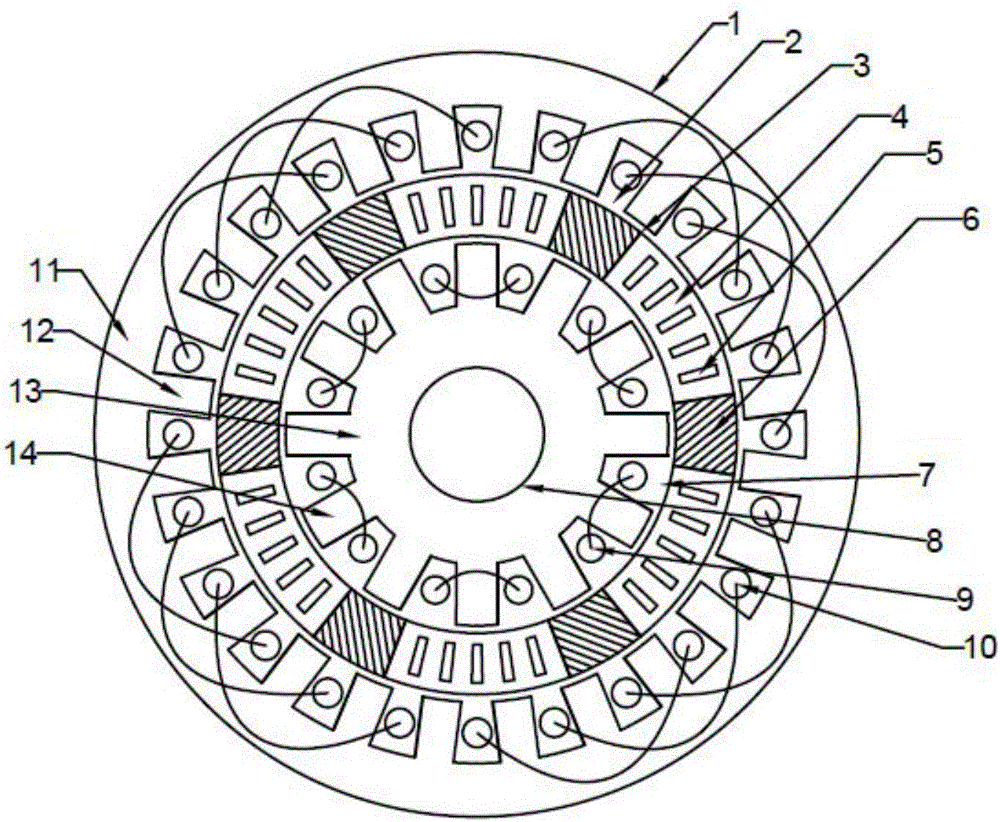

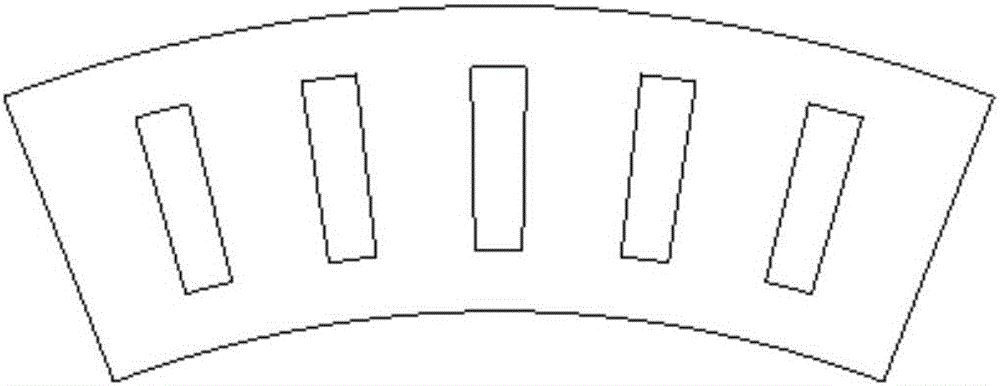

[0029] Such as figure 1 As shown, the outer stator, the rotor, and the inner stator are concentrically arranged, and from the outside to the inside, they are the outer stator 1, the outer air gap 2, the rotor 3, the inner air gap 7, and the inner stator 8; the inner stator 1 includes the outer stator yoke 11. Outer stator teeth 12 and distributed power windings 10 embedded in slots; the inner stator 8 includes inner stator yokes 13, inner stator teeth 14 and distributed control windings 9 embedded in slots; the rotor 3 includes Evenly distributed magnetically permeable core block 4 and non-magnetically permeable material block 6, the structure of the permeable magnetic core block 4 is as follows figure 2 As shown, the interior contains a magnetic isolation groove 5, and the magnetic isolation groove is not connected with the inner and outer air gaps.

[0030] Reluctance rotor field modulation double-stator brushless double-fed motor, including outer stator, rotor and inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com