Paper-inserting apparatus for paper-inserting robot for electric motor

A robot and motor technology, applied in manipulators, program-controlled manipulators, laying solid insulation, etc., can solve the problems of large differences in the propulsion depth of insulating paper, high production cost of motors, affecting the quality of motors, etc., and achieve high consistency of paper insertion depth. , compact structure, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

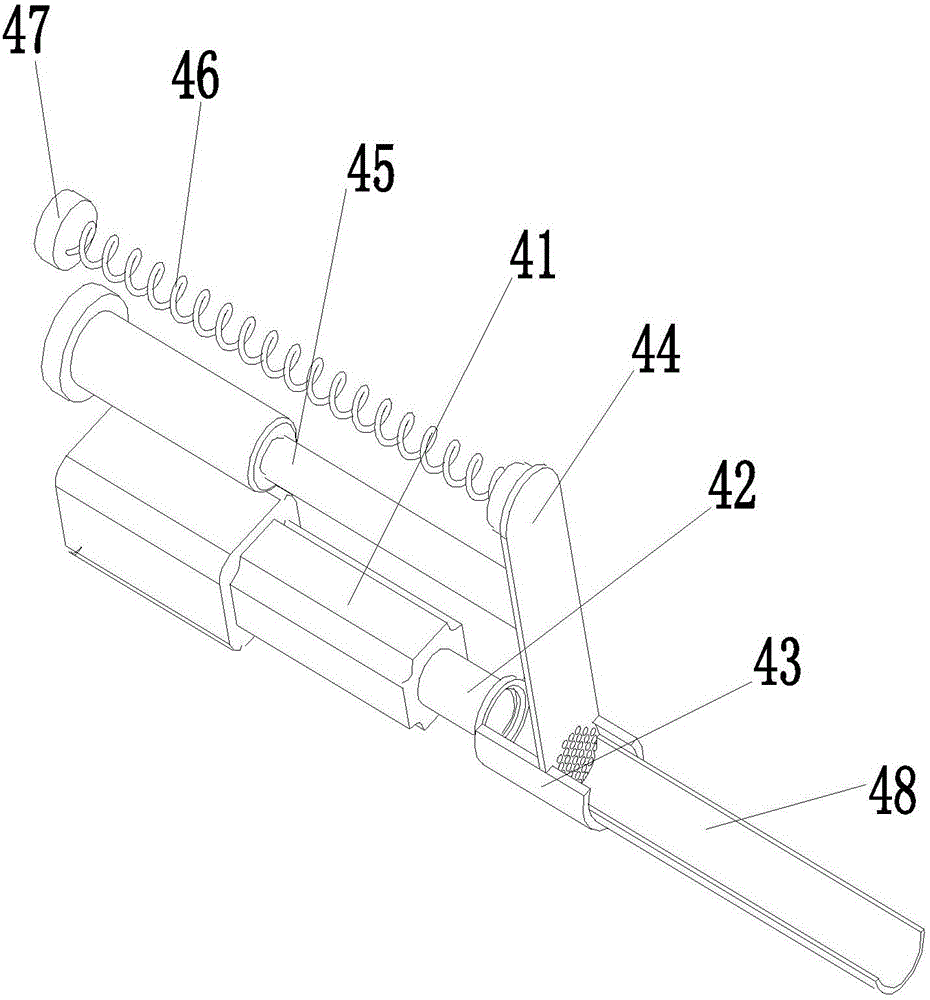

[0013] Such as figure 1 As shown, a paper insertion device for a motor paper insertion robot includes a micro air pump 41, a suction nozzle 42, a C-shaped sleeve 43, a pressure plate 44, a paper insertion electric push rod 45, a return spring 46, a mounting column 47 and insulating paper 48 ; The lower end of the micro air pump 41 is equipped with a suction nozzle 42, and the material of the suction nozzle 42 is a rubber material, the suction nozzle 42 is a hollow circular platform structure, the C-type sleeve 43 is located directly below the suction nozzle 42, and the C-type sleeve 43 It is connected with the suction nozzle 42 by thermal expansion and contraction technology. The pressure plate 44 has a waist-shaped thin plate structure. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com