Motor blank

A technology for punching and punching motors, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of motor efficiency reduction, high-frequency harmonics, and noise increase, so as to improve efficiency and reduce magnetic flux leakage coefficient , noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

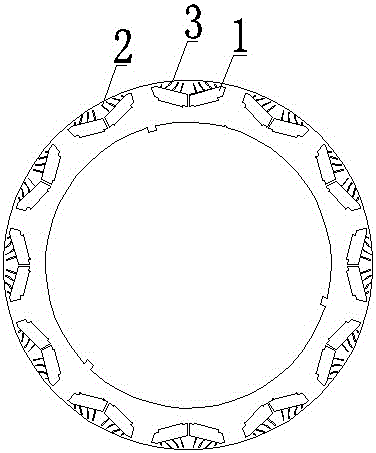

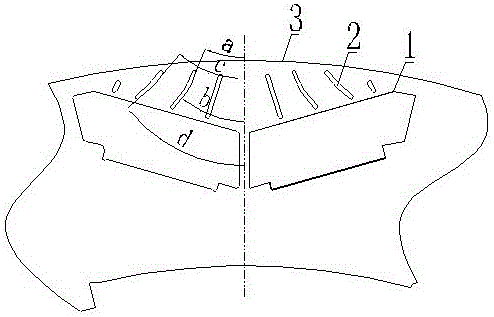

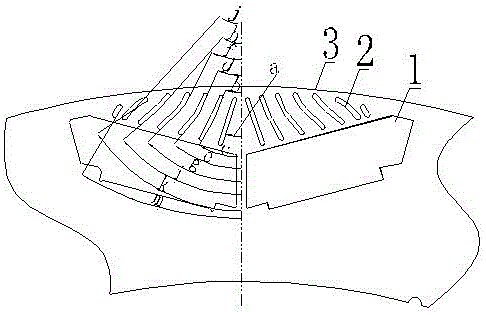

[0015] As shown in the figure, this embodiment includes a punching body 3, and the punching body has 12 or more magnetic steel hole groups distributed along its circumferential direction, and each magnetic steel hole group includes two V-shaped distribution holes with openings outward. Corresponding to each magnetic steel hole group, there are two sets of magnetic force line guide holes 2 symmetrically distributed. Each magnetic flux guide hole 2 is a straight line or a broken line or an arc, or a combination of at least two of the above. Each magnetic force line guide hole 2 is in the shape of converging toward the axial direction of the magnetic steel hole group from the inside of the punch body to the outside. In this embodiment, there are eight magnetic force line guide holes 2 corresponding to each magnetic steel hole group. The middle pair of magnetic force line guide holes 2 is a straight line with an angle of 19° with the axis of the magnetic steel hole group. The ou...

Embodiment 2

[0017] As shown in the figure, this embodiment includes a punching body 3, and the punching body has 12 or more magnetic steel hole groups distributed along its circumferential direction, and each magnetic steel hole group includes two V-shaped distribution holes with openings outward. Corresponding to each magnetic steel hole group, there are two sets of magnetic force line guide holes 2 symmetrically distributed. Each magnetic flux guide hole 2 is a straight line or a broken line or an arc, or a combination of at least two of the above. Each magnetic force line guide hole 2 is in the shape of converging toward the axial direction of the magnetic steel hole group from the inside of the punch body to the outside. In this embodiment, there are fourteen magnetic force line guide holes 2 corresponding to each magnetic steel hole group. The innermost pair of magnetic force line guide holes 2 is a straight line with an included angle of a=19° with the axis of the magnetic steel ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com