Rotor, method of manufacturing the same, and motor including the rotor

一种转子、转子芯的技术,应用在转子、制造该转子以及包括该转子的马达领域,能够解决产生异物、磁体不能被固定、成本粘合剂难以应用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, configuration and operation according to the present invention will be described in detail with reference to the accompanying drawings. In the description with reference to the drawings, like elements are designated with like reference numerals regardless of the drawing numbers, and duplicate descriptions thereof are omitted. Although the terms 'first', 'second', etc. may be used to describe various elements, these elements should not be limited by these terms. These terms are only used to distinguish one element from another.

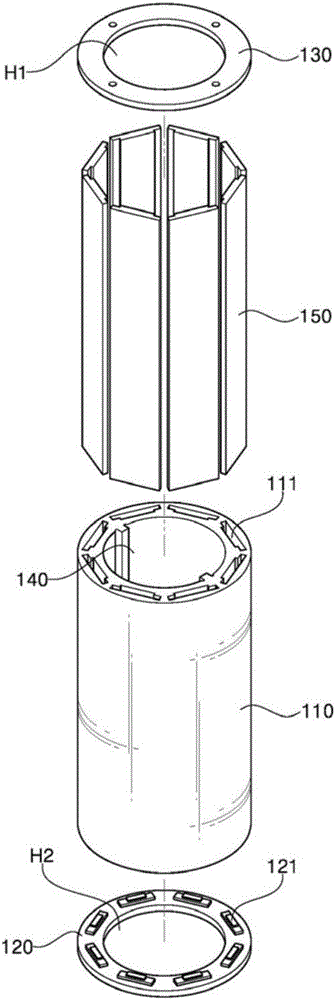

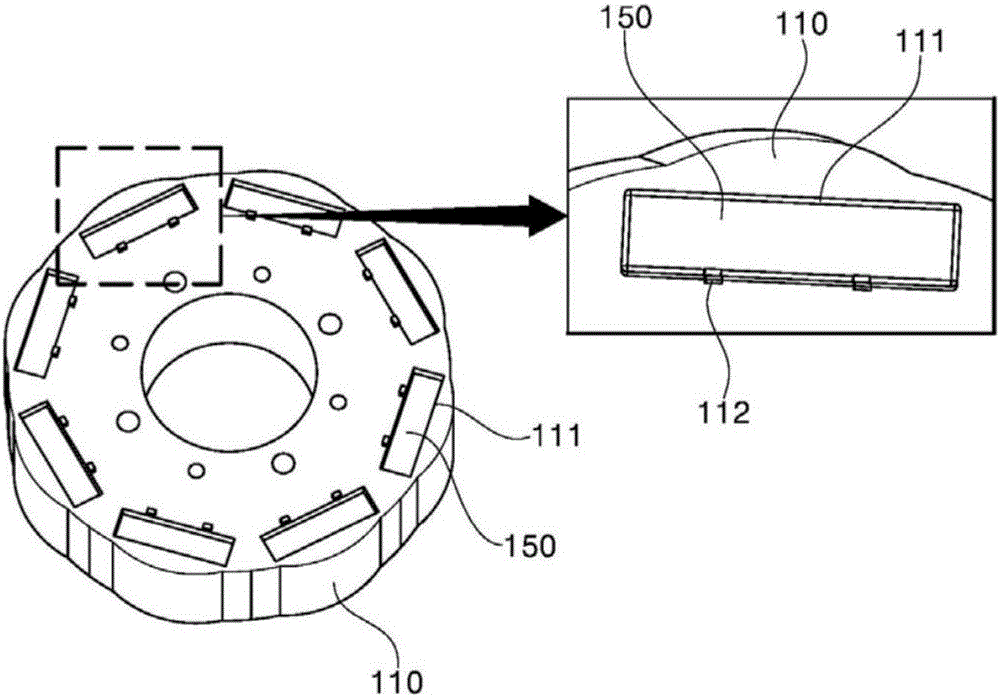

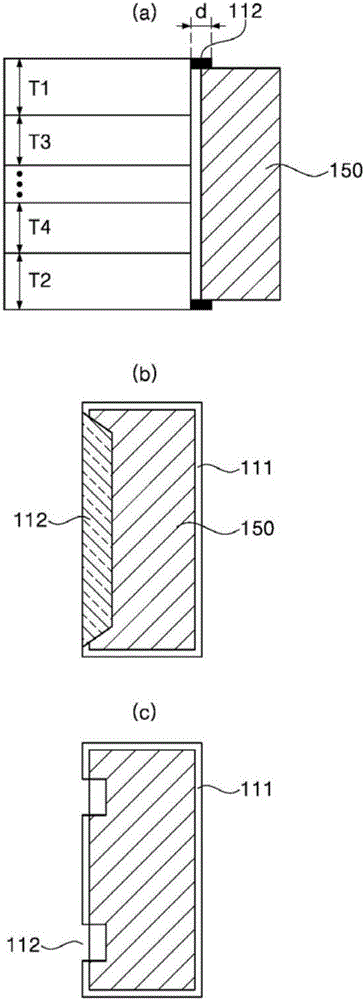

[0016] figure 1 is a schematic diagram for describing the structure of a rotor according to an embodiment of the present invention, and figure 2 is shown figure 1 Schematic diagram of the enlarged main part of the trochanter. also, image 3 is a schematic cross-sectional view for describing the structure of a rotor according to an embodiment of the present invention, and Figure 4 is a process diagram for describing the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com