Spherical silicon-oxygen-carbon negative electrode composite material and preparation method and application thereof

A technology of composite materials and spherical silicon, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems that the preparation process is not suitable for industrial production, and the charging and discharging efficiency is low, so as to avoid the heat treatment process and control the particle size , the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

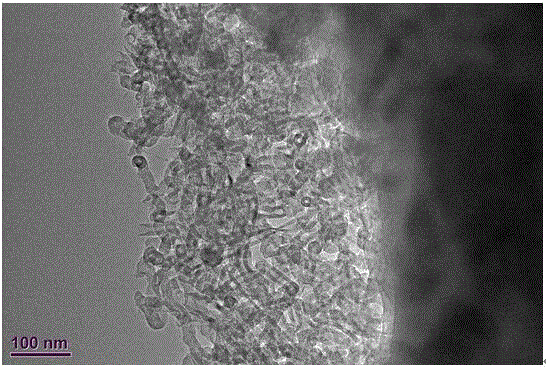

Image

Examples

Embodiment 1

[0034] (1) Liquid-phase carbon coating: 250g of 200-mesh SiO purchased x The sample and the dispersant sodium carboxymethyl cellulose with a mass fraction of 1.5% are ground by a sand mill until the particle size is less than 1 μm, the solvent is acetone, and the solid content is 10%, then 250g of natural graphite with an average particle size of 4.7μm and 46g of The polyvinyl alcohol is stirred and dispersed at a high speed, the stirring speed is 500rpm, the time is 0.5h, and then spray-dried and granulated; the inlet temperature of the spray granulator is 220°C, the outlet temperature is 100°C, the frequency of the feeding pump is 10Hz, and the frequency of the materialization disc is 250Hz; the obtained carbon Source coated spherical SiO x / Graphite particles are put into an atmosphere furnace to heat up and sinter, the atmosphere is nitrogen plus 10% hydrogen, the heating rate is 1°C / min, the sintering temperature is 400°C, and the time is 4 hours to obtain amorphous carb...

Embodiment 2

[0043] (1) Liquid-phase carbon coating: 300g of 200-mesh SiO purchased x The sample and the dispersant sodium carboxymethyl cellulose with a mass fraction of 1.5% were ground by a sand mill until the particle size was less than 1 μm, the solvent was acetone, and the solid content was 10%, then 200 g of natural graphite with an average particle size of 4.7 μm and 46 g of The polyvinyl alcohol is stirred and dispersed at a high speed, the stirring speed is 500rpm, the time is 0.5h, and then spray-dried and granulated; the inlet temperature of the spray granulator is 220°C, the outlet temperature is 100°C, the frequency of the feeding pump is 10Hz, and the frequency of the materialization disc is 250Hz; the obtained carbon Source coated spherical SiO x / Graphite particles are placed in an atmosphere furnace to heat up and sinter, the atmosphere is nitrogen plus 10% hydrogen, the heating rate is 1°C / min, the sintering temperature is 500°C, and the time is 4 hours to obtain amorph...

Embodiment 3

[0047] (1) Liquid-phase carbon coating: 200g of 200-mesh SiO purchased x The sample and the dispersant sodium carboxymethyl cellulose with a mass fraction of 1.5% were ground by a sand mill until the particle size was less than 1 μm, the solvent was ethanol, and the solid content was 10%, then 300 g of natural graphite with an average particle size of 4.7 μm and 46 g of The polyvinyl alcohol is stirred and dispersed at a high speed, the stirring speed is 500rpm, the time is 0.5h, and then spray-dried and granulated; the inlet temperature of the spray granulator is 220°C, the outlet temperature is 100°C, the frequency of the feeding pump is 10Hz, and the frequency of the materialization disc is 250Hz; the obtained carbon Source coated spherical SiO x / Graphite particles are placed in an atmosphere furnace to heat up and sinter, the atmosphere is nitrogen plus 10% hydrogen, the heating rate is 1°C / min, the sintering temperature is 400°C, and the time is 6 hours to obtain amorph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com