Preparation method of zinc oxide piezoresistor ceramic chip

A varistor, zinc oxide technology, applied in the direction of varistor core, varistor, and resistors with lead-out terminals, etc., can solve the problem of affecting product quality and work efficiency, slow manual swinging, manual spreading Powder separation and other problems, to overcome human error, high quality, reduce production and processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention provides a method for preparing zinc oxide varistor tiles, comprising the following steps:

[0034] (1) Carrying out batching, mixing, grinding and granulating the zinc oxide varistor raw materials to form porcelain powder, which also includes the following steps:

[0035] (2) The porcelain powder in step (1) is sent into a press, and the porcelain powder is pressed into green bodies of different shapes by the press. In this embodiment, the green body is 38mm in diameter and 150mm in length. A cylindrical green body with a density of 3.2;

[0036] (3) Put the green body into a firing bowl, and obtain a zinc oxide varistor ceramic body after debinding and sintering. The debinding temperature is 700°C, and then it is sent to a kiln at 1200°C for sintering to become Left and right zinc oxide piezoresistor cylindrical ceramic bodies; the step of putting the green body into the firing pot is as follows: the green body is rolled down through the track, and sen...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that the way of taking materials is different

[0047] Such as Figure 6 As shown, the reclaiming device in this embodiment includes a first conveyor 1 and a second conveyor 2, and the first conveyor 1 is also provided with a baffle plate 11 to prevent the cylindrical blank from being caused by two conveyors. The drop caused by asynchrony, the first conveyor 1 is driven by the main conveyor 12, the first conveyor 1 is used to transport the cylinder blank 4 from the forming end to the bowl loading area, and the second conveyor 2 transports the empty sagger to the In the charging area, the loaded blanks are transported into the debinding furnace. The second conveyor 2 is also equipped with a sagger 3 for loading the cylinder blanks into the furnace for debinding and firing. The sagger 3 is equipped with The first loading space 31 and the second loading space 32, an isolation belt 33 is arranged between the first ...

Embodiment 3

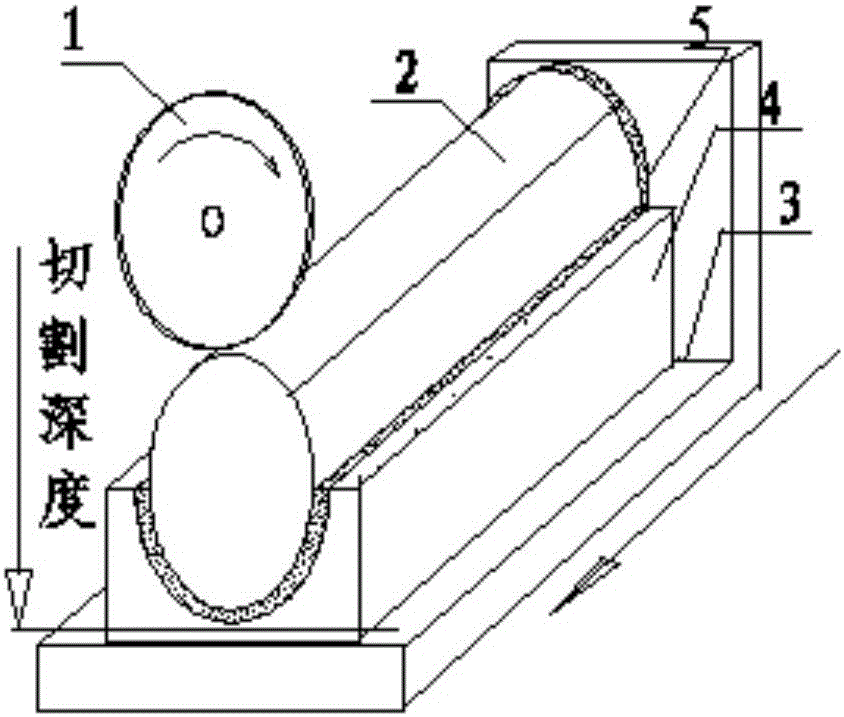

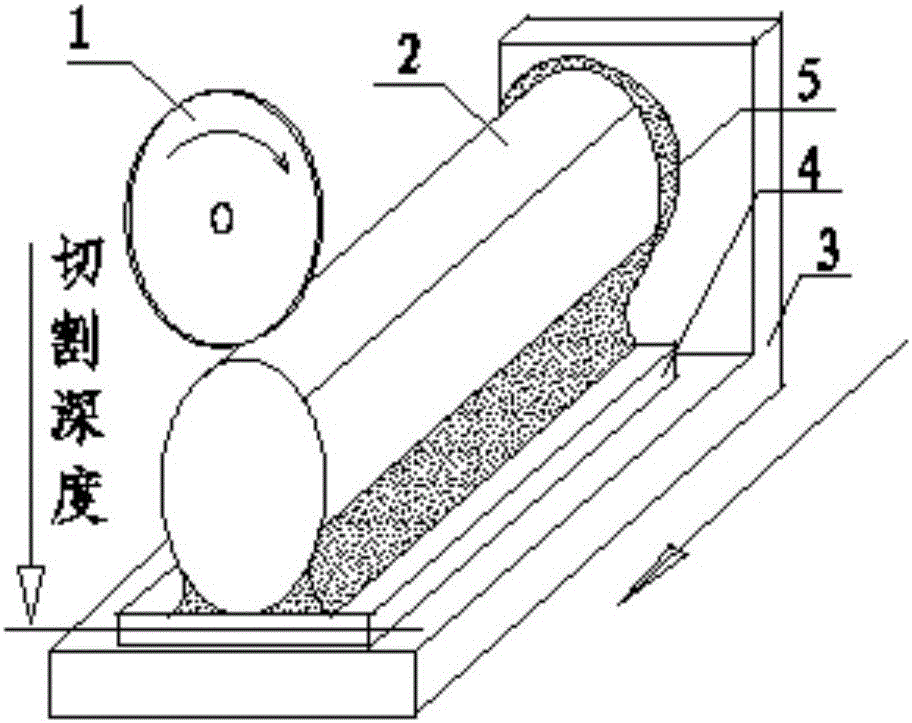

[0051] Such as Figure 7 and Figure 8 As shown, the production process of this embodiment is the same as that of Example 1, the difference is that the shape of the pressed blank and the cutting thickness are different, and the present embodiment uses a high-pressure formula, such as Figure 7 and Figure 8 As shown, the size of the pressed blank is 30×26×280mm rectangular body, and the thickness of the ceramic body is 2.6mm. This kind of product is used for the protection of communication power system.

[0052] The preparation method of a zinc oxide varistor tile provided by the present invention greatly improves the degree of production automation. At the same time, since the thickness of the pressing cylinder is not high, the number of times of pressing in the same batch is small, and the leakage of material is also small. The material utilization rate is high, eliminating the need to adjust the pressure and density of labor and time when pressing tablets with the same di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com