Method for acquiring axial uniform temperature section of standard test piece

A standard test piece and acquisition method technology, applied in the field of high-temperature mechanical performance testing of materials, can solve problems such as poor temperature uniformity, and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

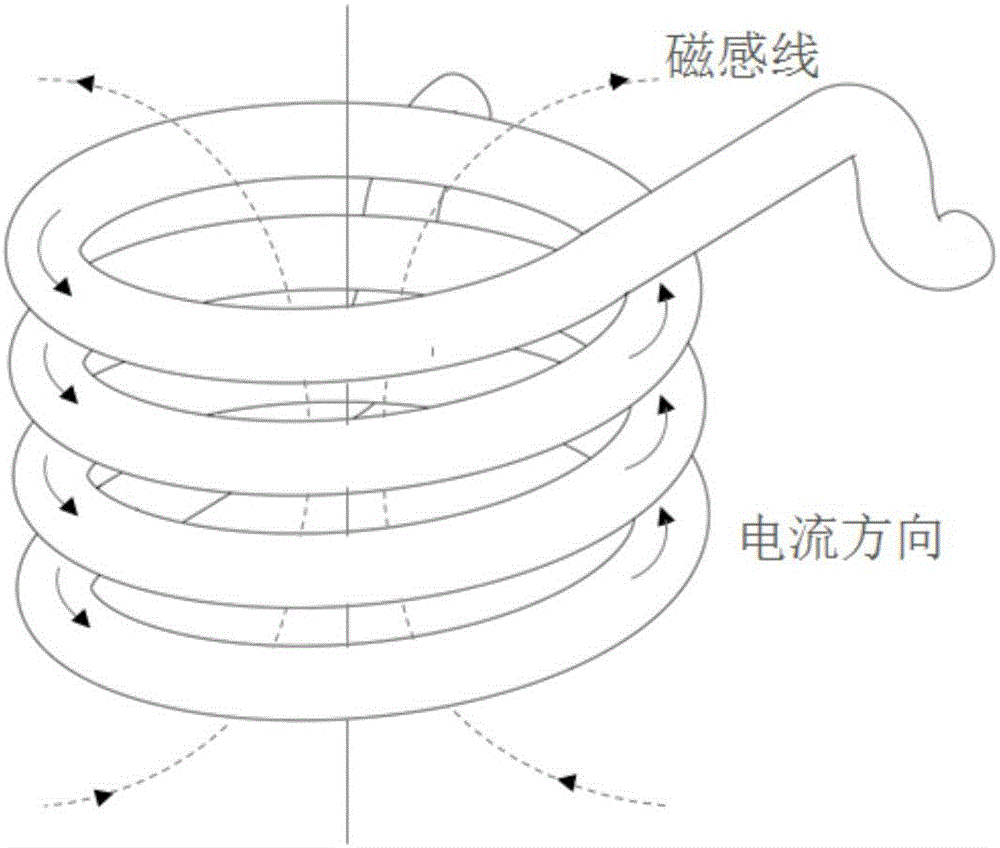

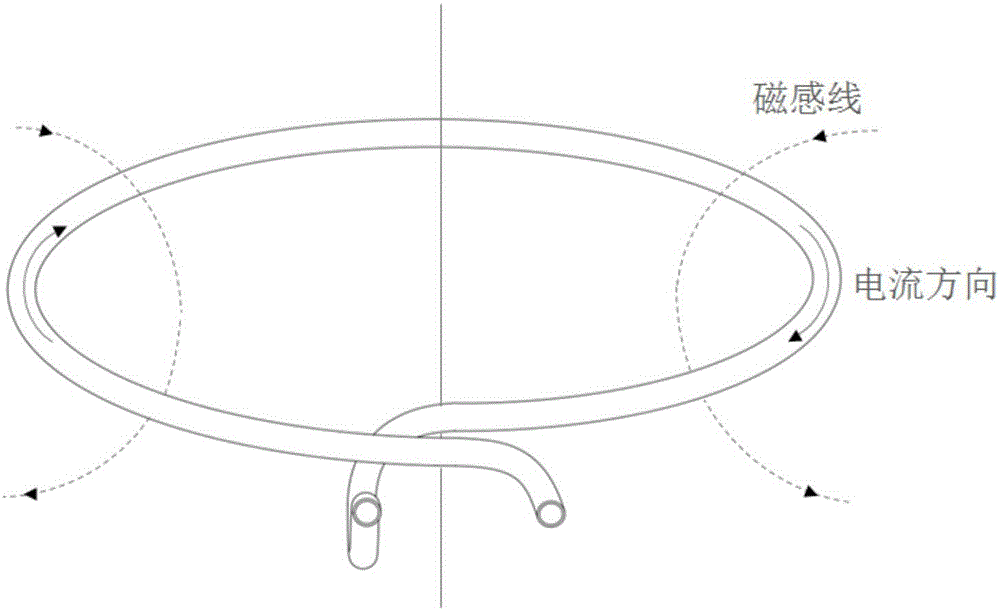

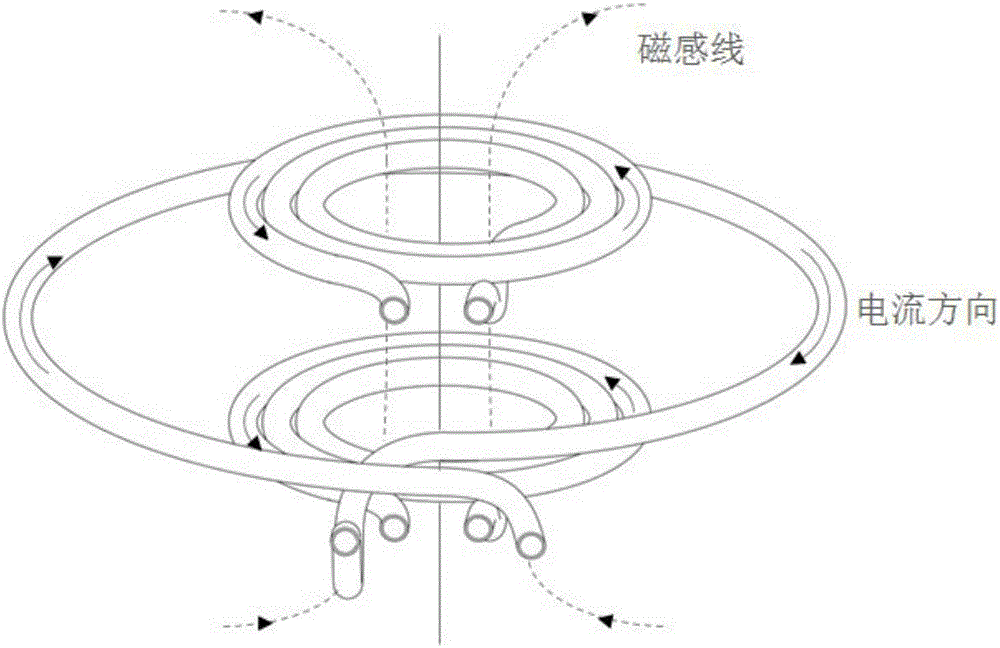

[0019] A high temperature mechanical standard specimen such as Figure 4 As shown, the temperature in the examination section should be as uniform as possible during the test. In order to obtain a better axial temperature uniform section, the present invention adopts the following methods: (1) Make three independent induction heating coils: two of them are vortex-shaped induction heating coils with smaller inner diameters, and the inner diameter range is 40mm to 60mm ,(Such as Figure 5 shown), one is a single-turn induction heating coil with a larger inner diameter, and its inner diameter ranges from 60mm to 150mm, (such as Figure 6 (2) The two coils with small inner diameters have the same inner diameter and are located at the upper and lower ends of the standard test piece. The large diameter coil is located in the middle of the test piece. The current flow direction is opposite to that of the two small diameter coils. When installing, ensure that the three coils are conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com