Slice ice machine evaporator

An evaporator and flake ice machine technology, which is used in evaporator/condenser, ice making, ice making, etc., can solve the problems of welding seam cracking, affecting normal use, welding seam leakage, etc., to improve quality, reduce Detection cost, clever design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

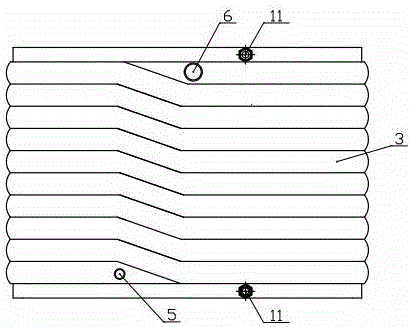

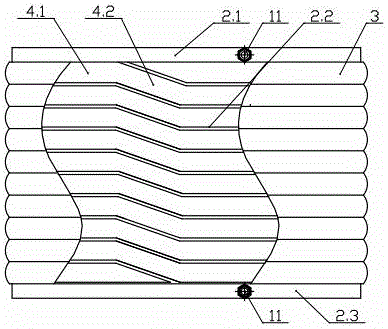

[0025] Such as Figure 1 to Figure 5 As shown, the evaporator of the flake ice machine of the present invention includes an inner cylinder 1, a partition 2 and an arc-shaped sealing plate 3, and the partitions 2 are welded at intervals along the outer wall of the inner cylinder. According to the difference of the welding positions of the partitions 2, the partitions The plate 2 is divided into an upper end face partition 2.1, a middle partition 2.2 and a lower end face partition 2.3. The thickness of the upper end face partition and the lower end face partition is thicker than that of the middle partition. The arc-shaped sealing plate 3 is lap-welded on the outer ends of two adjacent partitions 2 , and the arc-shaped sealing plate 3 , the partitions 2 and the outer wall of the inner cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com