Refrigeration system and refrigerated transport vehicle with same

A refrigeration system and throttling element technology, applied in the field of refrigeration systems and refrigerated transport vehicles, can solve problems such as affecting the reliability of refrigeration units, affecting the quality of refrigerated goods, and temperature fluctuations in refrigerated compartments, achieving stable pressure, preventing frequent shutdowns, maintaining temperature stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

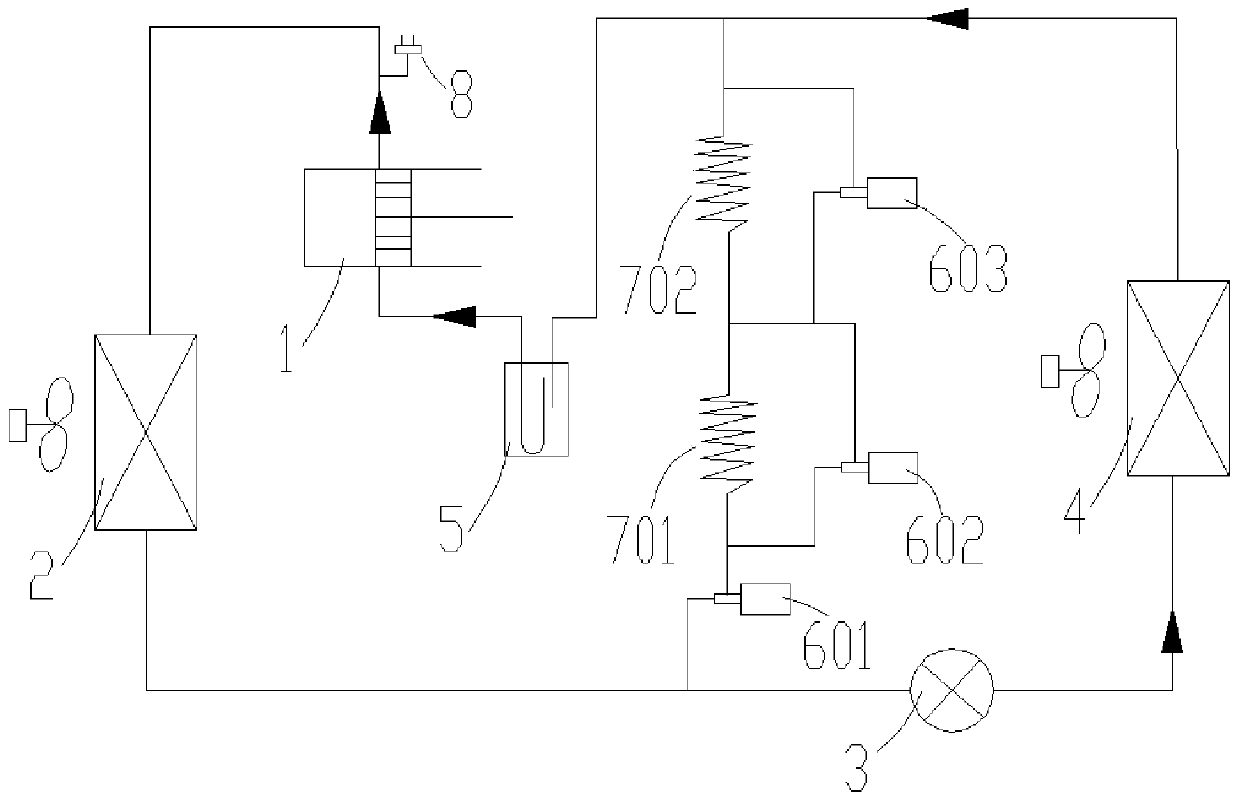

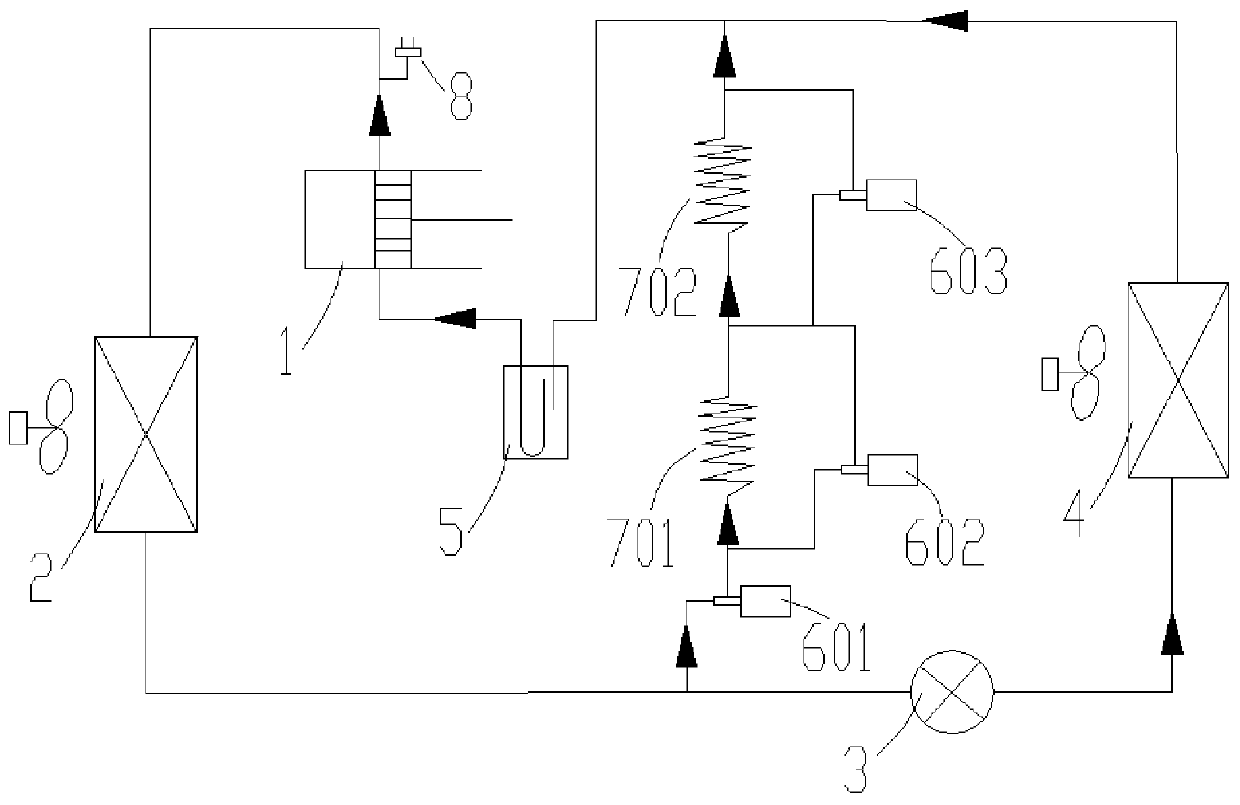

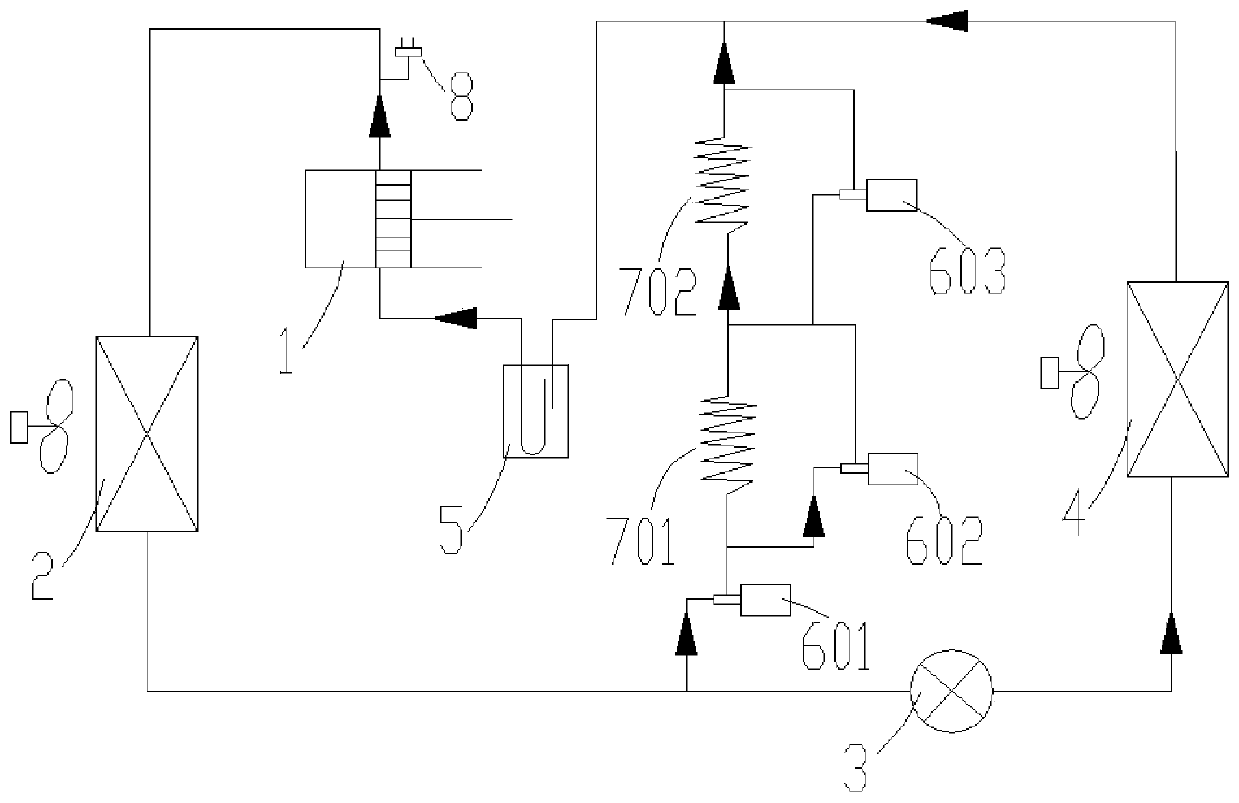

[0023] see first figure 1 , the present invention provides a refrigeration system, which includes a compressor 1 , a condenser 2 , a throttling component 3 and an evaporator 4 . In order to reduce the disadvantages caused by the high pressure of the system, the refrigeration system of the present invention also includes an unloading branch, and the unloading branch is connected in parallel with the evaporator branch. Wherein, the evaporator branch refers to the branch including the evaporator 4 , that is, the pipeline section formed in series by the evaporator 4 and the throttling component 3 . And wherein, the unloading branch includes at least a first unloading valve 601 and a first throttling element (preferably a capillary tube) 701 connected in series with the first unloading valve 601 .

[0024] That is to say, in the refrigeration system of the present invention, the exhaust port of the compressor 1 is connected to one end of the condenser 2, and the connection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com