Flanges capable of being positioned

A technology for positioning flanges and flanges. It is applied to flange connections, pipes/pipe joints/fittings, through components, etc. It can solve the problem of wasting manpower and material resources, and achieve the effect of stable positioning and connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

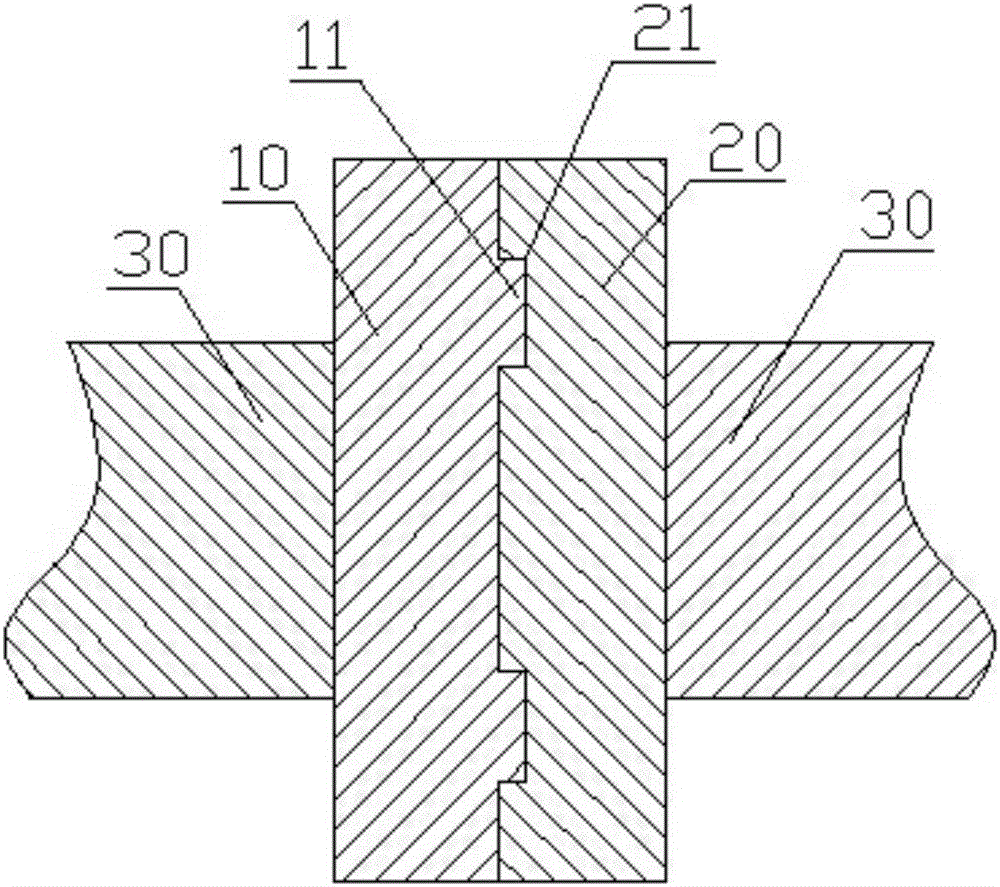

[0020] see figure 1 , as shown in the legend therein, a positionable flange includes a first flange 10 and a second flange 20 arranged left and right, the left end face of the first flange 10 and the left end of the second flange 20 The right end face is respectively connected with the pipeline 30, the right end face of the first flange 10 is protrudingly provided with a positioning protrusion 11, the left end face of the second flange 20 is concavely provided with a positioning groove 21, the first flange 10 The right end face of the second flange 20 is sealingly connected with the left end face of the second flange 20, and the positioning protrusion 11 is stuck in the positioning groove 21.

[0021] The positioning protrusion 11 is an annular protrusion, and the positioning groove 21 is an annular groove. The cross sections of the positioning protrusions 11 and the positioning grooves 21 are rectangular.

[0022] During assembly, preliminary positioning is performed throug...

Embodiment 2

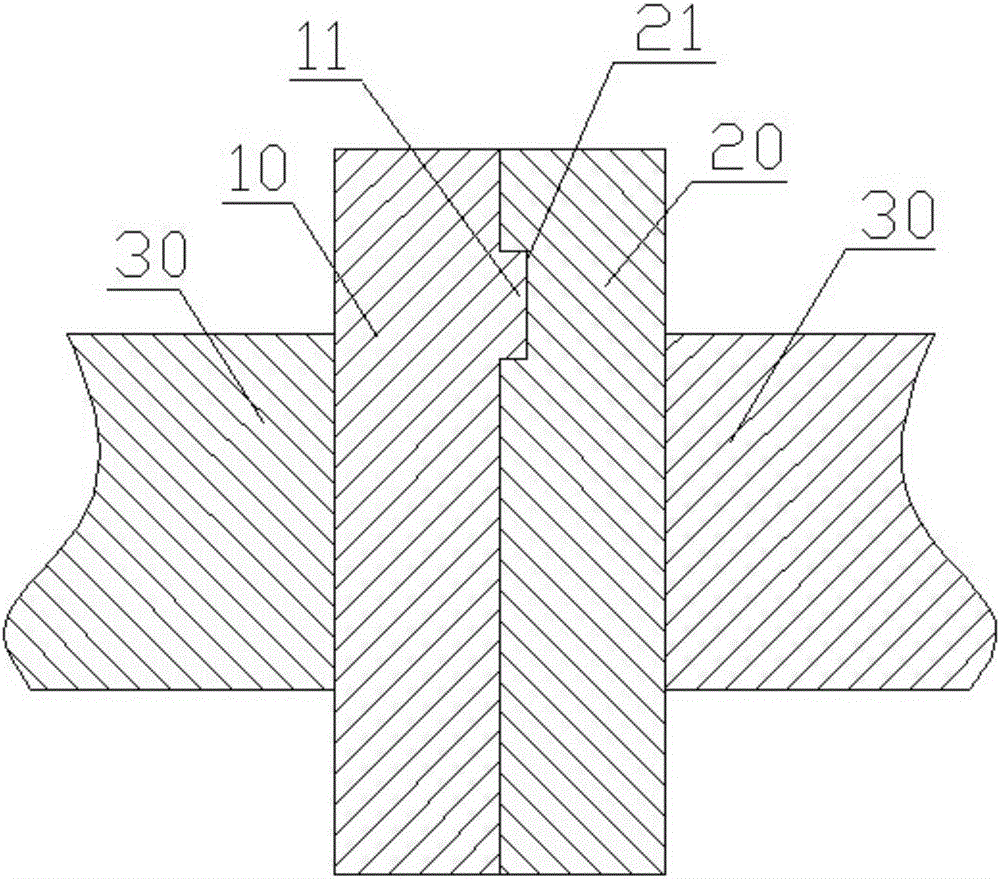

[0024] see figure 2 , as shown in the legend, the rest is the same as the first embodiment, the difference is that the positioning convex strip 11 is an arc-shaped convex strip, the positioning groove 21 is an arc-shaped groove, the arc-shaped convex strip is symmetrical front and back and passes through the first On the upper half of the flange 10 , the arc groove is symmetrical front and rear and passes through the upper half of the second flange 20 .

[0025] During assembly, preliminary positioning is performed through the positioning protrusions 11 and positioning grooves 21 , and then the connection between the first flange 20 and the second flange 21 is performed.

Embodiment 3

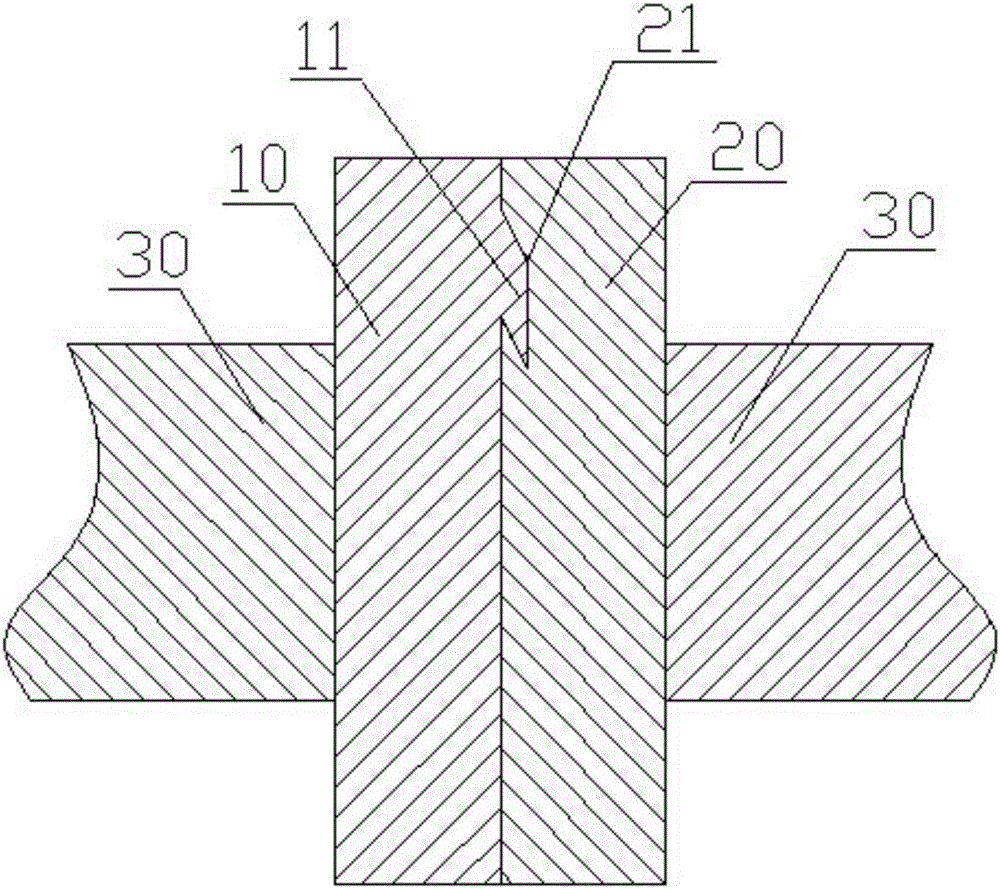

[0027] see image 3 , as shown in the legend, the rest is the same as the first embodiment, the difference is that the positioning convex strip 11 is a straight convex strip, the positioning groove 21 is a straight groove, the straight convex strip is symmetrical front and back and is located at the first On the upper half of the flange 10 , the arc-shaped groove is symmetrical front and rear and is located on the upper half of the second flange 20 . The cross sections of the positioning protrusions 11 and the positioning grooves 21 are parallelograms.

[0028] During assembly, the second flange 20 is assembled first, and then the first flange 10 is positioned on the second flange 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com