Method for automatically constructing support of confined concrete arch center for underground tunnel

A technology for confining concrete and construction methods, which is applied in tunnels, earth-moving drilling, tunnel lining, etc., to achieve the effects of good injection quality, guaranteed support strength, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

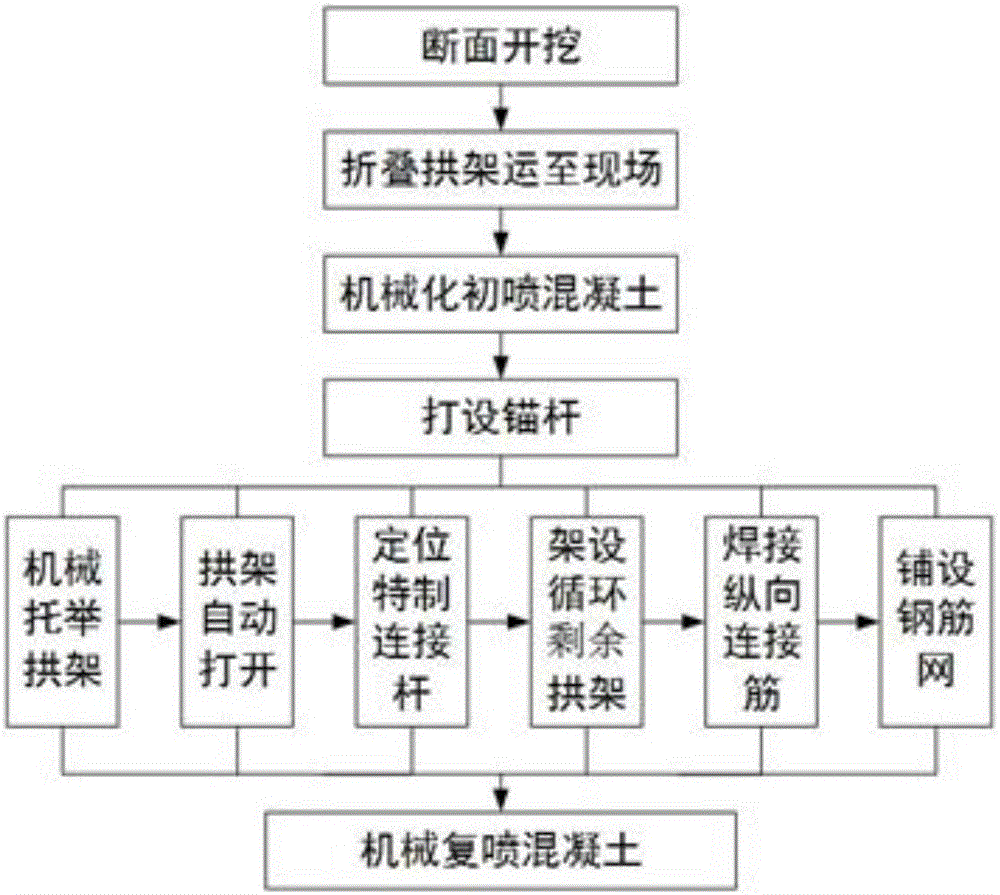

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

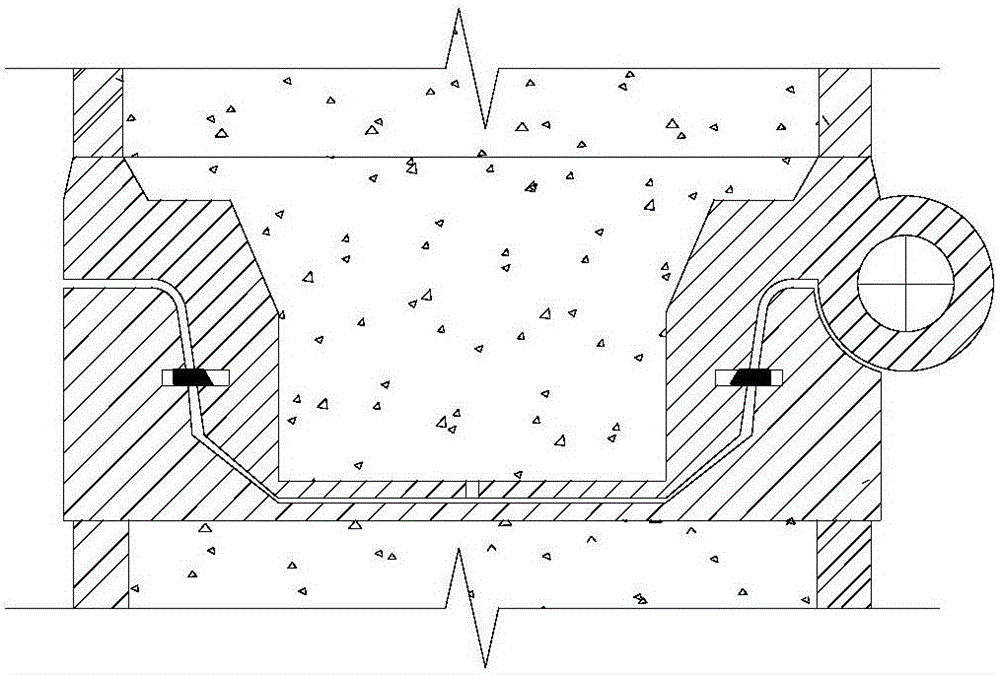

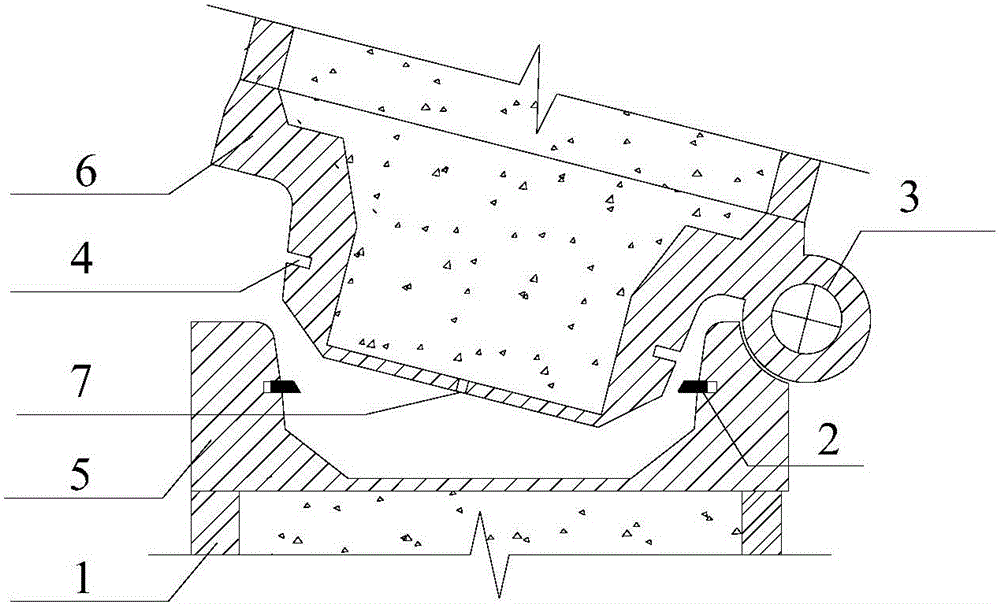

[0065] Figure 2(a), Figure 2(b) and Figure 5 As shown, a constrained concrete arch frame suitable for underground tunnels consists of several sections. The joints of adjacent sections are hinged, and the contact surfaces of the joints of two adjacent sections are set to cooperate with each other. The contact surface structure of one section is set It is a protruding structure 6, and the contact surface structure of the other section is set as a notch structure 5 that cooperates with the protruding structure 6. There is also a pair of holes between the protruding structure 6 and the notch structure 5 when the two are in a mated state. The two are clamped and fixed, and each section is a composite structure filled with concrete in square steel or round steel.

[0066] Wherein, the constrained concrete arch frame is square steel or round stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com