Fixture and clamp applying same

A fixture and clamp arm technology, applied in the field of hanger structure, can solve the problems of affecting the surface quality of workpieces, reducing production efficiency, increasing costs, etc., and achieve the effect of improving surface quality, increasing productivity, and reducing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

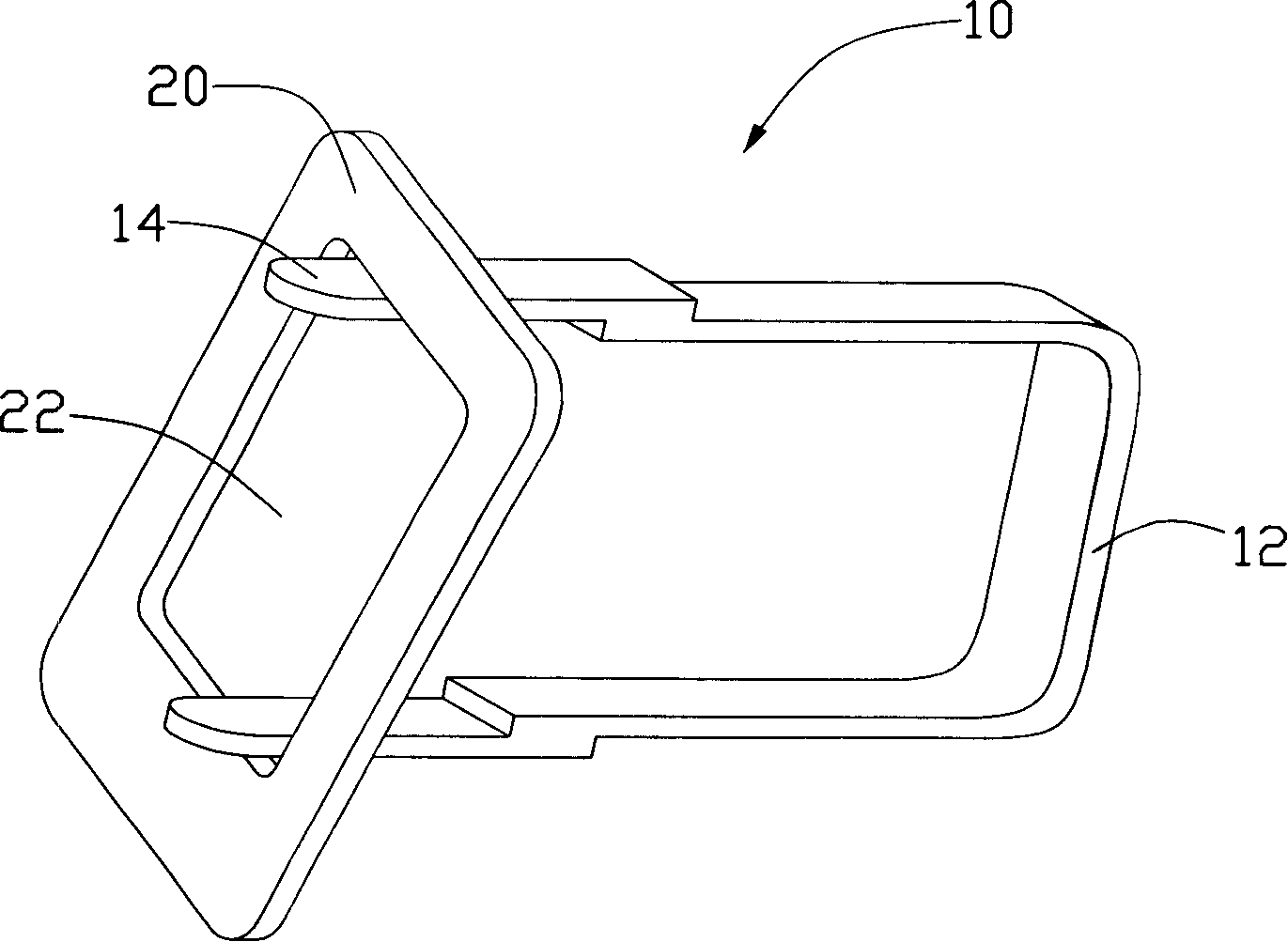

[0013] The fixture and hanger structure of the present invention are applied in the process of performing dip-dyeing treatment on workpieces.

[0014] The preferred embodiment of the clamp of the present invention is described by taking the structure of the hanger using the clamp as an example.

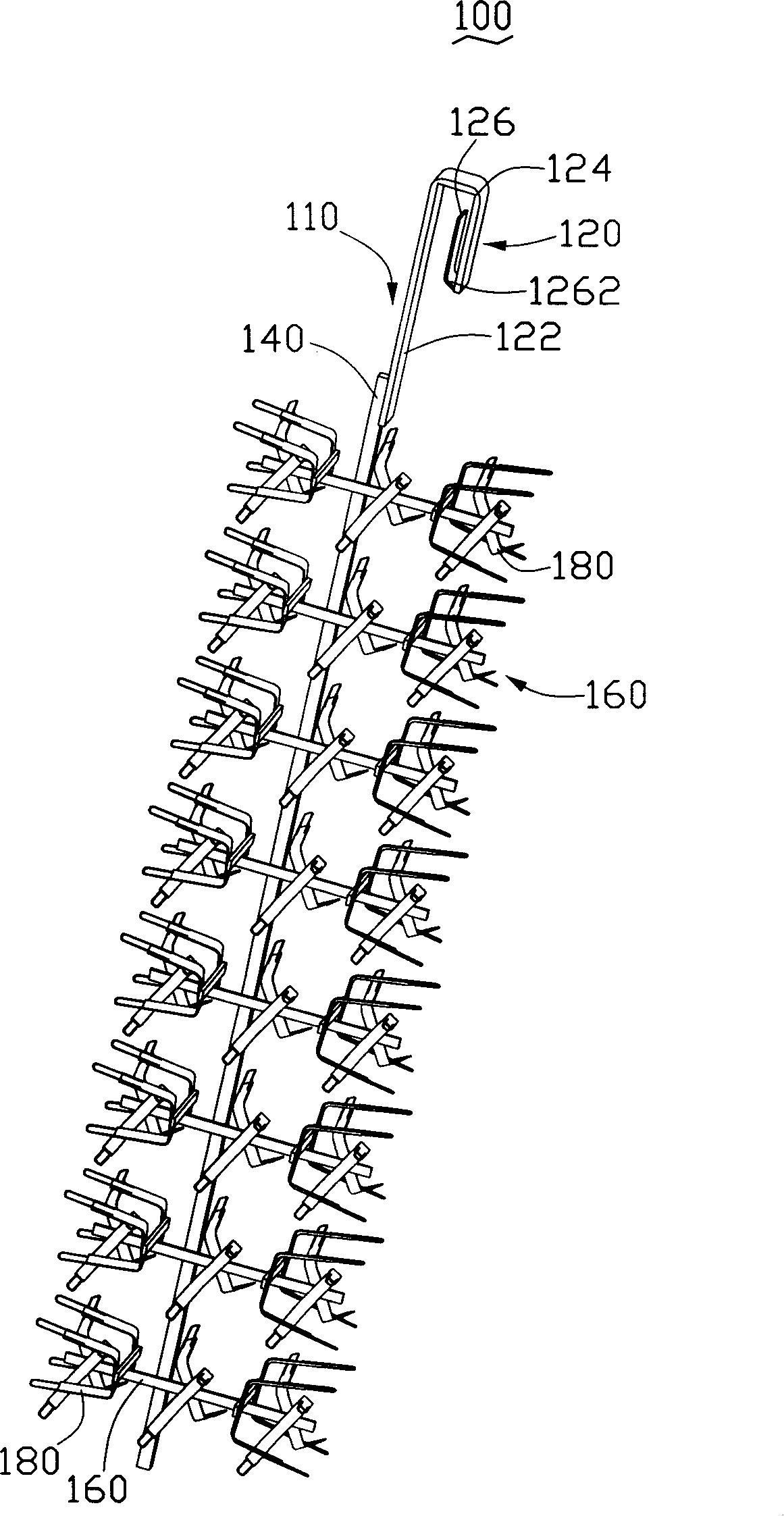

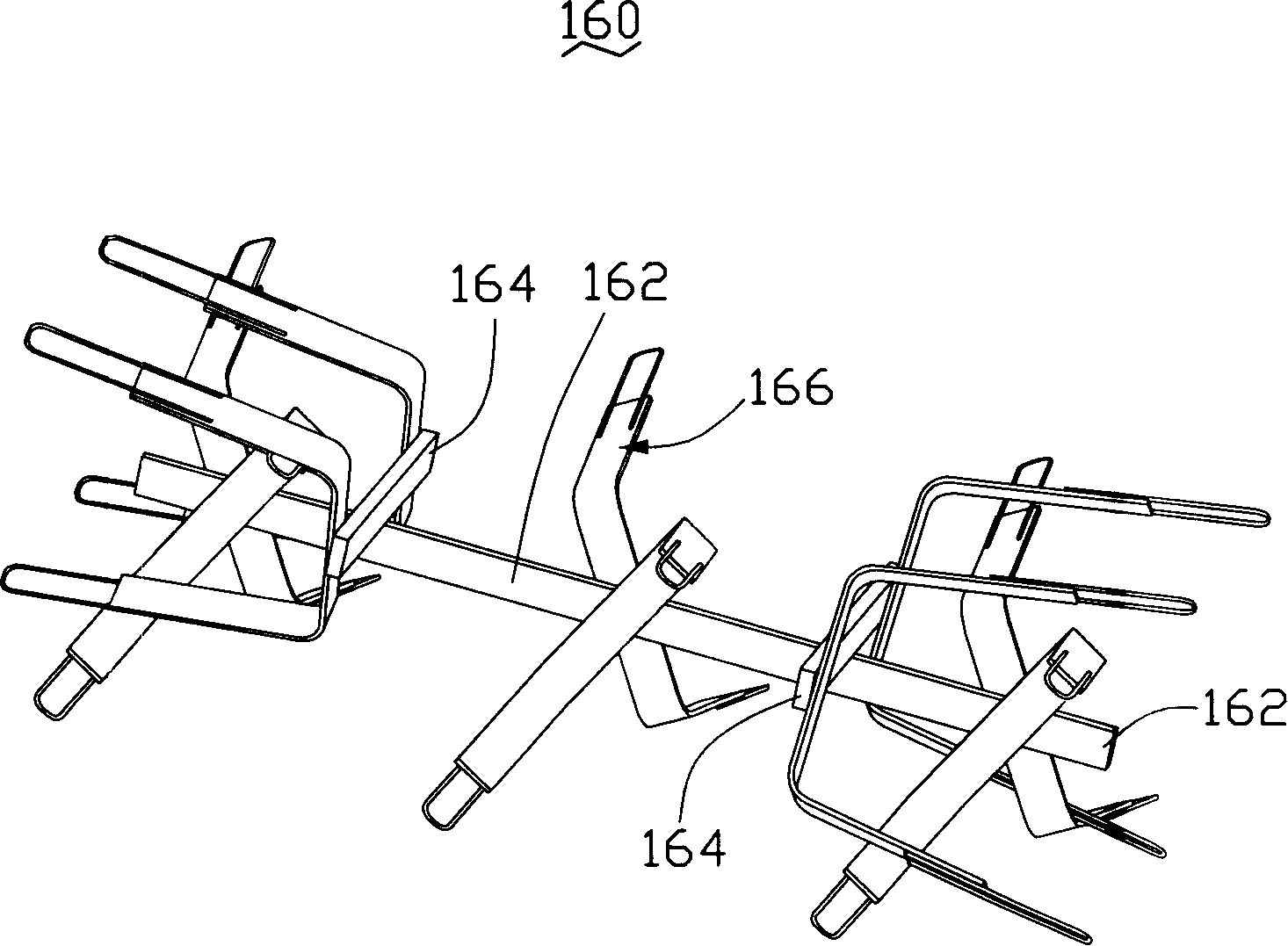

[0015] see figure 2 , the hanger structure 100 is used in anodizing and dip-dyeing processes for workpieces. The hanger structure 100 includes a hanger 110 and a plurality of sets of supports 160 , and the sets of supports 160 are equidistantly arranged on the hanger 110 .

[0016] The hanging frame 110 includes a hanging rod 120 and an extending rod 140 , one end of the hanging rod 120 is fixedly connected with one end of the extending rod 140 .

[0017] The hanging rod 120 is made of conductive material, and includes a connecting portion 122 , a hook 124 and a conductive sheet 126 . The hook 124 is disposed at one end of the connecting portion 122 . A bent portion 1262 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com