Support-free overhead zip line construction method of two-way single-layer cable net structure

A technology of cable net structure and construction method, which is applied in the direction of building structure, construction material processing, construction, etc., can solve the problems of high cost of construction measures, large investment in tooling, high technical requirements, etc., and achieve easy cable protection and tension The effect of high pulling efficiency and low cost of measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

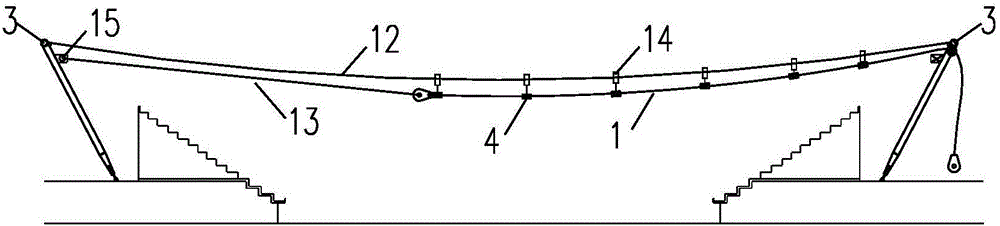

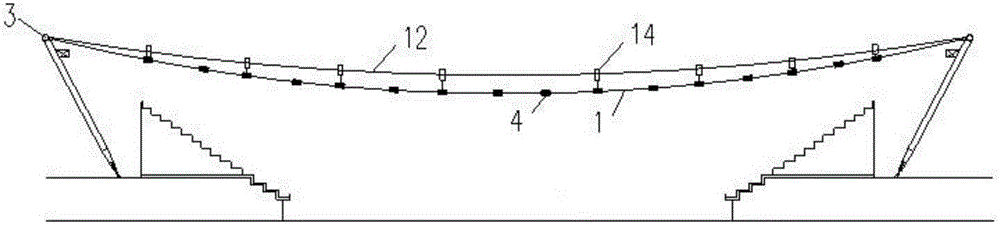

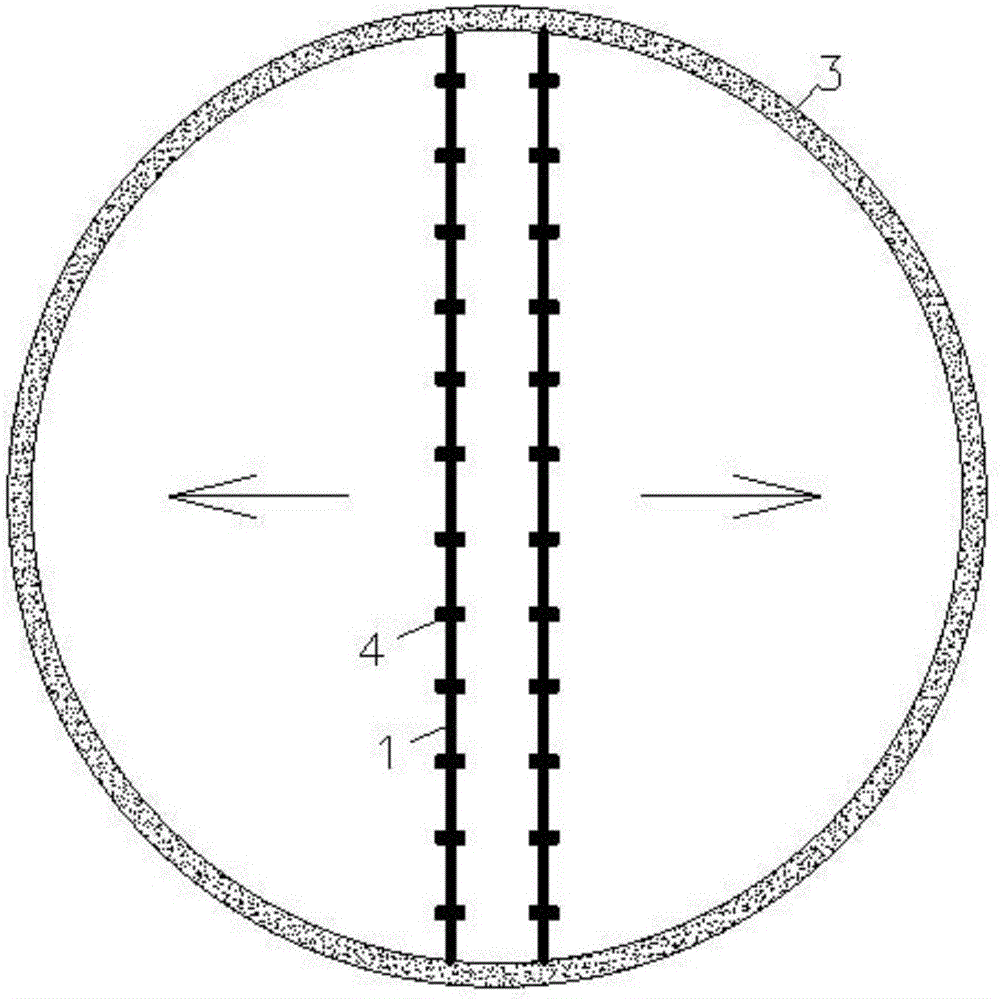

[0033] Attached below Figure 1-11 The present invention is described further.

[0034] The construction method of a two-way single-layer cable net structure high-altitude zipline without support of the present invention is to install the load-bearing cable 1 first and then the stabilizing cable 2 in sequence. For load-bearing cable 1: firstly, spread out the cable straightly on the ground and install and fasten the bottom plate 5 and middle plate 6 of the cable clamp 4, and install the guide cable 12, traction cable 13 and traction equipment on the design position corresponding to the load-bearing cable 1 Tooling 15, and then the load-bearing cable 1 is installed to the high-altitude design position and connected with the outer pressure ring 3 to anchor by traction in the way of a zipline, until all the load-bearing cables 1 are installed in place. For the stabilizing cable 2: First, unfold the stabilizing cable 2 straightly on the ground, lay the catwalk 16 resting on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com