Heat preservation and sound insulation structure of ground layer of building and construction method of heat preservation and sound insulation structure

A floor surface and sound insulation technology, which is applied to floors, insulation layers, building structures, etc., can solve problems such as thermal insulation and sound insulation, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

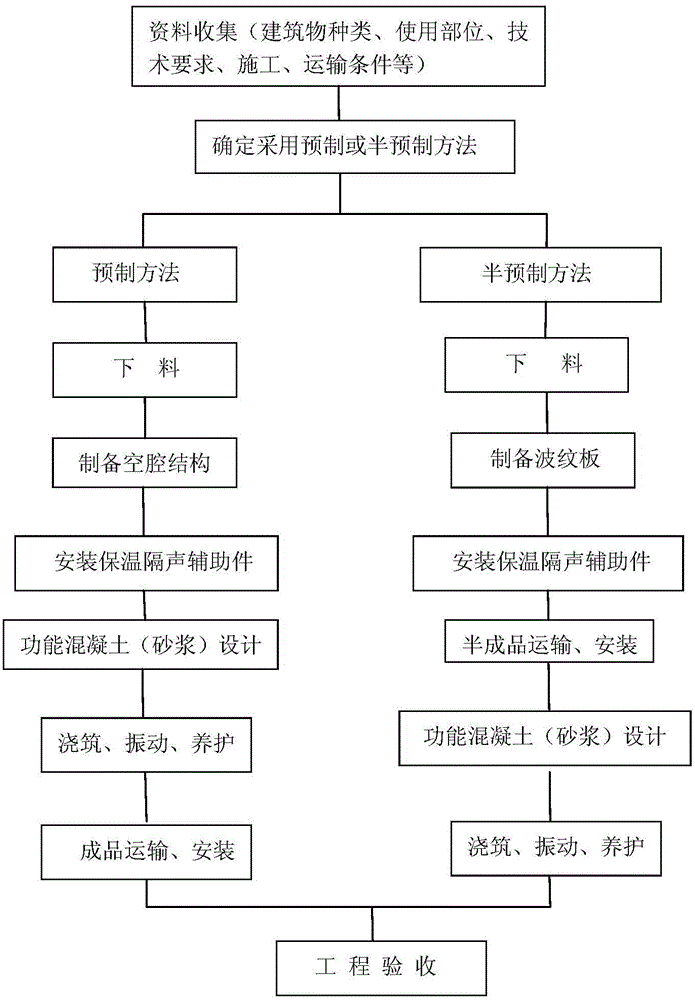

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Cast-in-place thermal insulation and sound insulation board (basic type).

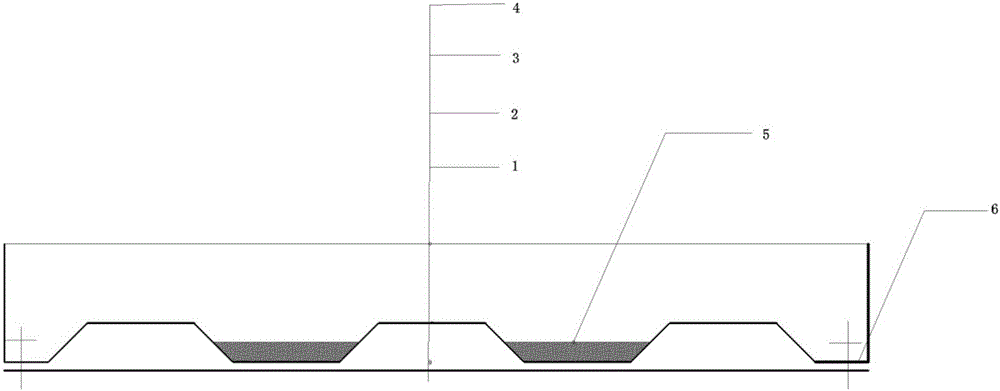

[0044] (1) Prepare metal corrugated board and install thin rubber sound insulation sheet, such as figure 2 Shown.

[0045] (2) Preparing thermal insulation and sound insulation concrete, the specific formula is as follows: cement (P.O42.5) 350kg / m 3 , Fly ash (Class II ash) 50kg / m 3 , Water 180kg / m 3 , 2.5mm rubber particles 10kg / m 3 , Floating beads 30kg / m 3 , Medium sand 450kg / m 3 , Primary EPS particles 3kg / m 3 , Fine stone (5-10mm) 650kg / m 3 , Several other additives.

[0046] (3) The performance indicators of the prepared concrete are as follows: the strength is 15.9MPa, the bulk density is 1600kg / m 3 , The thermal conductivity is 0.58W / (m.K).

[0047] (4) Install the metal corrugated plates on the floor with expansion bolts, and control the gap between the metal corrugated plates at 3-5mm to prevent the metal corrugated plates from squeezing each other due to temperature deformation.

[...

Embodiment 2

[0050] Example 2: Factory prefabricated insulation and sound insulation board (basic type)

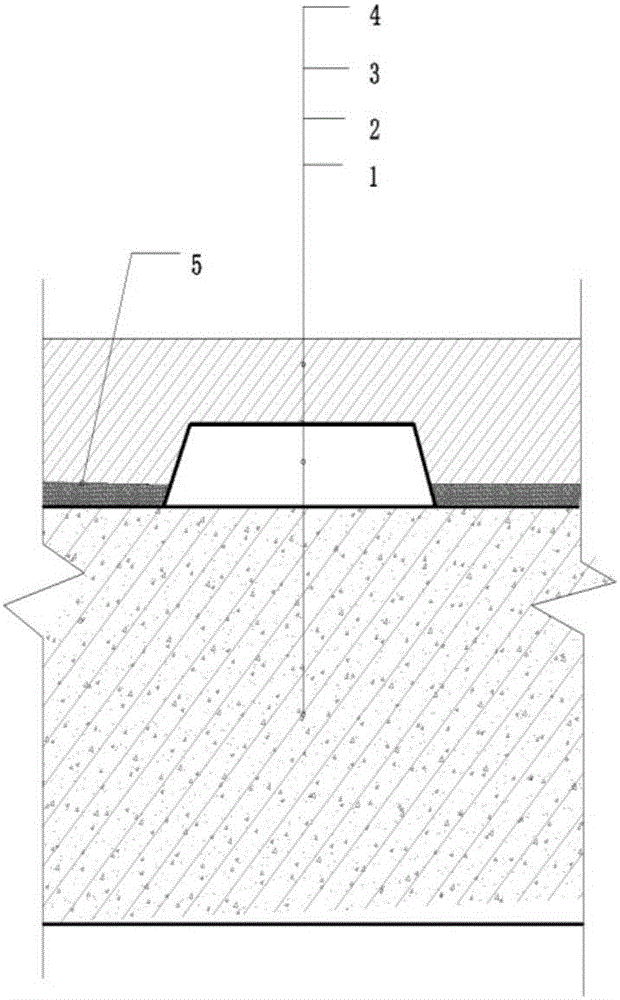

[0051] (1) Prepare a metal cavity and install a thin rubber sound insulation sheet, such as image 3 Shown.

[0052] (2) Preparing thermal insulation and sound insulation concrete, the specific formula is as follows: cement (P.O42.5) 350kg / m 3 , Fly ash (Class II ash) 50kg / m 3 , Water 180kg / m 3 , 2.5mm rubber particles 10kg / m 3 , Floating beads 30kg / m 3 , Medium sand 450kg / m 3 , Primary EPS particles 3kg / m 3 , Fine stone (5-10mm) 650kg / m 3 , Several other additives.

[0053] (3) The performance indicators of the prepared concrete are as follows: the strength is 15.9MPa, the bulk density is 1600kg / m 3 , The thermal conductivity is 0.58W / (m.K).

[0054] (4) Pouring the heat-insulating and sound-insulating concrete prepared and curing it for 14 days to make it have a certain strength.

[0055] (5) Transport to the construction site, and install by spring line. The gap between the control panel joi...

Embodiment 3

[0058] Example 3: On-site pouring type thermal insulation sound insulation board (high thermal insulation type).

[0059] (1) Prepare plastic corrugated board, install thin rubber sound insulation sheet and heat preservation auxiliary parts, such as image 3 Shown.

[0060] (2) Prepare heat insulation and sound insulation concrete, the specific formula is as follows: cement (P.O42.5) 300kg / m 3 , Fly ash (Class II ash) 50kg / m 3 , Water 200kg / m 3 , 2.5mm rubber particles 10kg / m 3 , Floating beads 30kg / m 3 , Medium sand 300kg / m 3 , Primary EPS particles 5kg / m 3 , Fine stone (5-10mm) 500kg / m 3 , Slag (3-5mm) 100kg / m 3 , Several other additives.

[0061] (3) The performance indicators of the prepared concrete are as follows: the strength is 8.9MPa, and the bulk density is 1200kg / m 3 , The thermal conductivity is 0.29W / (m.K).

[0062] (4) Install the metal corrugated plates on the floor with expansion bolts, and control the gap between the metal corrugated plates at 3-5mm to prevent the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com