Assembled type bathroom floor slab and construction method

A toilet, prefabricated technology, applied to floors, water supply devices, waterway systems, etc., can solve the problems of large human factors, difficult waterproof layer treatment, slow construction speed, etc. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

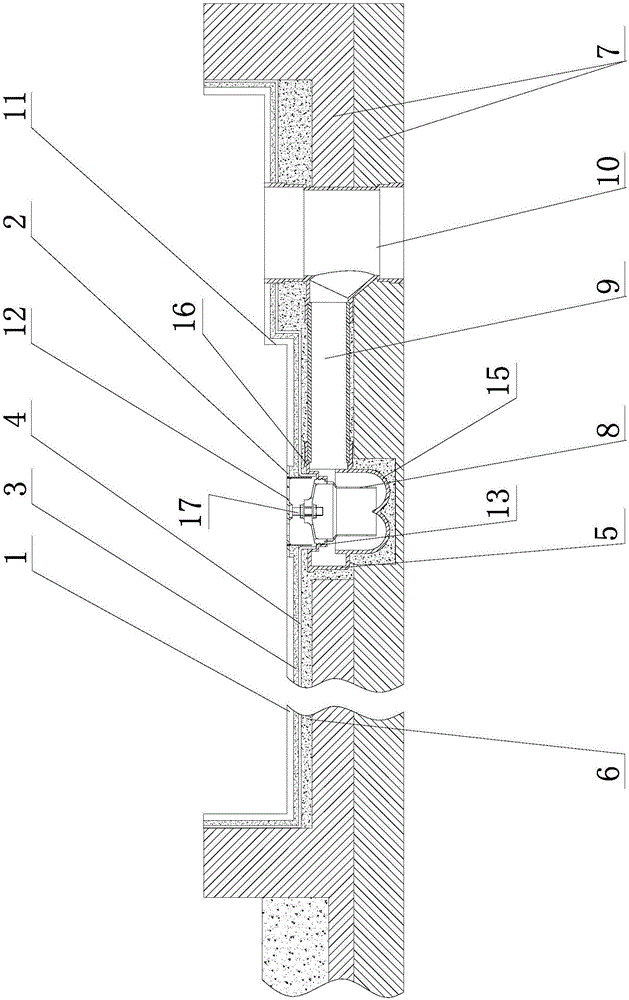

[0031] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0032] Such as figure 1 Shown, the technical solution that the present invention adopts for solving the above-mentioned technical problems is:

[0033] A prefabricated toilet floor, equipped with a built-in drainage system, including a drainage standpipe connection 10, a floor drain, and a floor drain horizontal pipe 9; And the surface layer 1, the surface layer adhesive layer 3, the waterproof layer 4 and the structural layer 7 are arranged in sequence below. A leveling protective layer 6 can be provided on the structural layer 7 for leveling when the surface of the structural layer 7 is uneven.

[0034] Described floor drain comprises floor drain housing 5 and floor drain cover 3, is provided with upper sealing platform 13 on the top of floor drain ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com